Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

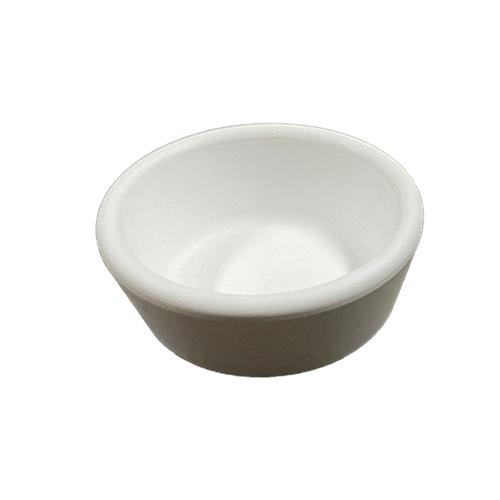

Overview of Boron Nitride Crucible:

Boron Nitride Crucibles are specialized laboratory equipment used primarily in materials science and metallurgy for the high-temperature processing of metals, ceramics, and other materials. These crucibles are made from boron nitride (BN), a chemical compound known for its unique properties.

Features of Boron Nitride Crucible:

- High Thermal Conductivity: Boron nitride has excellent thermal conductivity, which means it can transfer heat efficiently. This property facilitates the maintenance of a uniform temperature distribution within the crucible during the heating process.

- Chemical Inertness: BN is chemically inert to many substances at high temperatures, making it resistant to corrosion or reaction with molten metals and salts.

- Low Coefficient of Thermal Expansion: Boron nitride exhibits a low coefficient of thermal expansion, which minimizes the risk of cracking or breaking due to thermal shock when exposed to rapid temperature changes.

- Electrical Insulation: At room temperature and up to very high temperatures, boron nitride acts as an electrical insulator, which is important for certain applications where electrical conductivity could be problematic.

- Lubricity: Boron nitride has a lubricating effect even at high temperatures, which can be advantageous for certain manufacturing processes.

Specifications of Boron Nitride Crucible:

| Specification | Details |

| Material Composition | Hexagonal Boron Nitride (h-BN) |

| Maximum Operating Temperature | Up to 2100°C (3812°F) in non-oxidizing atmospheres; up to 900°C (1652°F) in air |

| Thermal Conductivity | High thermal conductivity, promoting uniform heat distribution |

| Coefficient of Thermal Expansion | Low, minimizing risk of thermal shock |

| Chemical Resistance | Resistant to most molten metals, salts, acids, and bases |

| Electrical Resistivity | High electrical resistivity at elevated temperatures |

| Purity | Typically >99% BN |

| Surface Finish | Smooth, sometimes with a polished finish |

| Common Sizes | Varies widely, from small laboratory sizes to larger industrial capacities |

| Shape Availability | Cylindrical, boat-shaped, rectangular, custom shapes available |

| Mass Loss at High Temperatures | Minimal mass loss under high-temperature conditions |

| Porosity | Generally low, contributing to chemical inertness |

| Color | White or light gray |

| Special Features | Some may come with lids or covers; options for coatings or reinforcements |

Applications of Boron Nitride Crucible:

1. Metallurgy and Metal Processing

Melting and Casting: Boron nitride crucibles are used for melting and casting metals and alloys that require high temperatures and resistance to chemical attack. They are especially suitable for reactive metals like aluminum, titanium, and magnesium.

Heat Treating: These crucibles are ideal for heat treating processes such as annealing, quenching and tempering where maintaining a non-reactive environment is critical.

2. Ceramic and Glass Manufacturing

Material Synthesis: Boron Nitride crucibles provide an inert environment during the synthesis of advanced ceramics and glasses, preventing contamination and ensuring purity.

Firing and Sintering: Used for firing and sintering ceramic materials at high temperatures without risking contamination from the crucible material.

3. Chemical Industry

High-Temperature Reactions: Boron nitride crucibles can be used for conducting high-temperature chemical reactions, especially those involving corrosive or reactive substances.

Laboratory Analysis: In analytical chemistry, these crucibles are used for preparing samples for analysis by methods like X-ray fluorescence (XRF) spectroscopy, where contamination must be avoided.

4. Semiconductor Industry

Wafer Fabrication: The semiconductor industry uses boron nitride crucibles for growing single crystals and processing wafers, benefiting from the material’s ability to withstand high temperatures while remaining chemically inert.

Epitaxial Growth: Used in epitaxial growth processes for creating high-quality thin films on semiconductor substrates.

5. Research and Development

Experimental Work: Researchers use boron nitride crucibles for experimental work involving new materials or processes that require controlled high-temperature environments.

Development of New Materials: Crucial for developing new materials that need to be processed under stringent conditions, ensuring that the crucible does not interfere with the material properties being studied.

6. Nuclear Industry

Handling Radioactive Materials: Due to its chemical inertness and radiation resistance, boron nitride crucibles can be used in the handling and processing of radioactive materials, including waste management and fuel fabrication.

7. Optoelectronics

Crystal Growth: Utilized in the crystal growth processes for optoelectronic devices, which often require high-purity and high-temperature stability.

Company Profile

Advanced Ceramics founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2012, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Aluminum Nitride Ceramic Products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

FAQs of Boron Nitride Crucible

1.What is a boron nitride crucible?

A: A Boron Nitride Crucible is a specialized container used in laboratories and industrial settings for high-temperature applications, particularly in materials science, metallurgy, and chemical processing. It is made from boron nitride (BN), a compound known for its exceptional properties that make it suitable for handling extreme conditions.

2. What are the benefits of boron nitride crucible?

A: Boron Nitride Crucibles offer a range of benefits that make them particularly valuable for high-temperature applications in materials science, metallurgy, and chemical processing. Here are the key advantages: High Thermal Conductivity, Low Coefficient of Thermal Expansion, Excellent Electrical Insulation, High Temperature Stability, Non-Wetting Properties, Lubricity at High Temperatures, Versatility in Applications.

3. What industries use boron nitride crucible?

A: Boron nitride crucibles are widely used in industries such as metallurgy, ceramics, chemical industry, semiconductor, optoelectronics, pharmaceuticals, automotive and aerospace.

4. Can boron nitride crucibles be used in high-temperature environments?

A: Yes, boron nitride crucibles are exceptionally well-suited for use in high-temperature environments. Boron nitride crucibles can typically operate at temperatures up to 2100℃ (3812℉) in non-oxidizing atmospheres. In air, the maximum temperature is generally lower, around 900℃ (1652℉), due to oxidation concerns.

5. Are boron nitride crucibles environmentally friendly?

A: Boron nitride crucibles present several environmentally friendly attributes, primarily due to their durability, energy efficiency, and minimal contamination risks.

REQUEST A QUOTE

RELATED PRODUCTS

The Heat-Withstanding Hero in High-Tech Frontiers – High Purity Boron Nitride Ceramic Ring

Ceramic Boron Nitride Powder CAS 10043-11-5

Boron Nitride Ceramic Plate

Hexagonal BN Boron Nitride Ceramic Disk

High Mechanical Strength Boron Nitride Ceramics Cubic Boron Nitride Raw Materials