Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

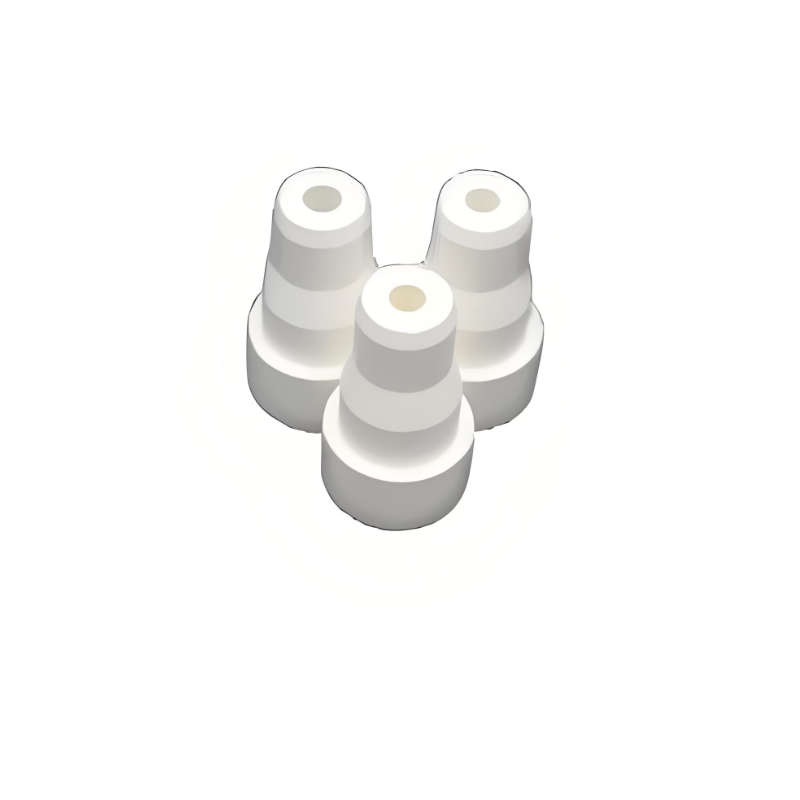

Overview of Boron Nitride Nozzle:

Due to the special properties of Boron Nitride (BN), Boron Nitride nozzles are specialized components used in a variety of high temperature and chemically reactive environments. These nozzles are designed to withstand extreme conditions, ensuring reliable performance in applications such as metal casting, glassmaking and additive manufacturing.

Features of Boron Nitride Nozzle:

- High Thermal Conductivity: Boron nitride has excellent thermal conductivity, which allows for efficient heat dissipation and uniform temperature distribution.

- Chemical Inertness: BN is highly resistant to chemical reactions with many substances, including molten metals, salts, acids, and bases, even at elevated temperatures.

- Low Coefficient of Thermal Expansion: This property minimizes the risk of thermal shock and cracking during rapid heating and cooling cycles.

- Electrical Insulation: Boron nitride acts as an electrical insulator, which can be important for certain applications.

- Non-Wetting Properties: Many molten materials do not adhere to boron nitride surfaces, facilitating easy cleaning and reducing material buildup.

Specifications of Boron Nitride Nozzle:

| Specification | Description |

| Material Type | Hexagonal Boron Nitride (h-BN) |

| Purity | >98% |

| Density | 2.10 – 2.25 g/cm³ |

| Porosity | <1% |

| Thermal Conductivity | 60 – 300 W/m·K (depending on grade and processing method) |

| Coefficient of Thermal Expansion | 4.0 x 10⁻⁶ /°C (at 20-1000°C) |

| Maximum Operating Temperature | Up to 2100°C in non-oxidizing atmospheres; up to 900°C in air |

| Electrical Resistivity | >10¹² Ω·cm at 20°C |

| Chemical Resistance | Excellent resistance to acids, alkalis, molten metals, and salts |

| Non-Wetting Properties | Resistant to wetting by many molten metals and glasses |

| Hardness (Mohs) | ~2 (softer than diamond but harder than most metals) |

| Flexural Strength | 150 – 300 MPa |

| Compressive Strength | 200 – 500 MPa |

| Surface Finish | Can be polished to very smooth surfaces (<0.5 µm Ra) |

| Tolerance | ±0.1 mm (can be tighter based on machining capabilities) |

| Nozzle Diameter | Customizable, typically ranges from 1 mm to several centimeters |

| Nozzle Length | Customizable, depends on application requirements |

| Shape and Design | Various shapes available including cylindrical, conical, and custom designs |

| Application-Specific Features | Special coatings or modifications for specific applications (e.g., anti-wear coatings) |

Applications of Boron Nitride Nozzle:

1. Metal Casting

Continuous Casting: Boron nitride nozzles are used in continuous casting processes for metals like aluminum, magnesium, and titanium. They ensure a steady flow of molten metal while resisting corrosion and maintaining dimensional stability.

Die Casting: Used in die casting operations where precise control of molten metal flow is essential. Their non-wetting properties prevent metal sticking and ensure smooth operation and clean castings.

2. Glass manufacturing

Molten Glass Handling: Used in the handling and molding of molten glass to provide a non-reactive surface that prevents contamination and ensures smooth flow. This is essential for producing high quality glass products free of impurities.

Glass Fiber Production: Essential in the production of glass fibers, where boron nitride nozzles help maintain consistent fiber diameter and quality by withstanding the high temperatures involved.

3. Additive Manufacturing (3D Printing)

Material Extrusion: In advanced manufacturing processes like fused filament fabrication (FFF), boron nitride nozzles enhance the extrusion process by reducing material adhesion and improving heat management. This leads to better print quality and fewer clogs.

Powder Bed Fusion: Powder bed fusion technology for metals and ceramics with excellent thermal stability to prevent contamination of the manufactured material.

4. Semiconductor Industry

Wafer Processing: Maintaining purity and preventing contamination is critical in the processing of semiconductor wafers. Boron nitride nozzles are used in all stages of wafer fabrication, including deposition and etching processes.

Crystal Growth: Used in crystal growth processes for semiconductors, ensuring that the environment remains free from contaminants that could affect the crystal structure.

5. Ceramics and Advanced Materials Processing

High Temperature Processing: Ideal for high temperature processing involving ceramics, superconductors and other advanced materials. Nozzles can withstand extreme conditions while maintaining structural integrity.

Sintering: Used in sintering furnaces to handle and dispense powders or gases, ensuring uniform heating and minimizing the risk of contamination.

6. Chemical industry

High-temperature reactions: Used for high-temperature chemical reactions, especially those involving corrosive or reactive substances. The inertness of boron nitride prevents unwanted chemical reactions.

Laboratory applications: Important for laboratory scale experiments and pilot plants where precise control of temperature and chemical reactions is required.

7. Automotive and Aerospace

Advanced Material Development: These sectors rely on boron nitride nozzles for developing lightweight, high-strength materials suitable for high-performance applications. The nozzles facilitate precise control over material processing parameters.

8. Energy Sector

Fuel Cell Technology: Used in the development and manufacturing of fuel cells, where high-temperature stability and chemical inertness are critical for performance and durability.

Nuclear Industry: Employed in handling radioactive materials, including waste management and fuel fabrication, due to their resistance to radiation and chemical attack.

9. Pharmaceuticals

High-Temperature Processing: Used in pharmaceutical processes that require high-temperature treatments, ensuring that the materials remain uncontaminated and the process is reliable.

Company Profile

Advanced Ceramics founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2012, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Aluminum Nitride Ceramic Products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

FAQs of Boron Nitride Nozzle

1.What is a boron nitride Nozzle?

A: A Boron Nitride Nozzle is a specialized component used in various industrial processes, particularly those involving high temperatures and chemically reactive environments. It is made from boron nitride (BN), a compound known for its exceptional thermal and chemical properties.

2. What are the benefits of boron nitride Nozzle?

A: Boron Nitride Nozzles offer a multitude of benefits that make them indispensable in various high-temperature and chemically reactive applications. Here are the key advantages: High Thermal Conductivity, Low Coefficient of Thermal Expansion, Non-Wetting Properties, Mechanical Strength and Durability.

3. What industries use boron nitride Nozzle?

A: Boron nitride nozzles are utilized across a variety of industries due to their exceptional thermal, chemical, and mechanical properties. Such as metal casting, glass manufacturing, chemical industry, semiconductor, ceramic, 3D printing, automotive and aerospace.

4. Can boron nitride Nozzles be used in high-temperature environments?

A: Yes, boron nitride nozzles are particularly well-suited for use in high-temperature environments due to their exceptional thermal properties and chemical stability. Boron nitride nozzles can withstand temperatures up to 2100℃ in non-oxidizing atmospheres. In air, they can typically handle temperatures up to around 900℃ without significant degradation.

5. Are boron nitride Nozzles environmentally friendly?

A: Boron nitride nozzles exhibit several environmentally friendly characteristics, including durability, energy efficiency, minimal contamination, and sustainable manufacturing practices. While challenges exist, particularly regarding recycling and raw material extraction, the overall environmental benefits make them a favorable choice for many high-performance applications.

REQUEST A QUOTE

RELATED PRODUCTS

Customized Bn Gas Atomization Nozzle Boron Nitride Ceramic

Boron Nitride Factory Can Customize Boron Nitride Ceramic Tube

China Industrial Precision Customized Boron Nitride Ceramic Dowel Pin

High-Performance Boron Nitride Ceramic Pipe for Industrial Use

Boron Nitride Ceramic Tube Pipe Ceramic Protection Insulating Tube