Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

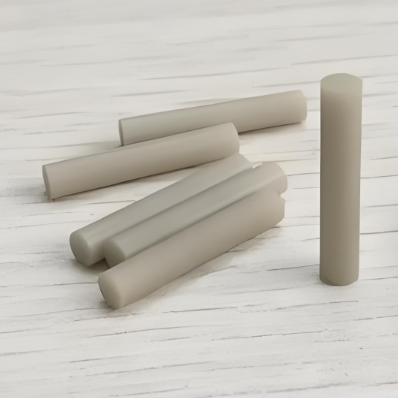

Overview of Aluminum Nitride Ceramic Rod

Aluminum Nitride (AlN) Ceramic Rods are advanced ceramic components that leverage the unique properties of aluminum nitride to serve critical functions in various high-performance applications. These rods are engineered to meet stringent requirements for thermal management, electrical insulation, and mechanical stability. Below is a comprehensive overview of AlN Ceramic Rods:

Properties of Aluminum Nitride Ceramic Rod

1. High Thermal Conductivity:One of the most notable features of AlN ceramic rods is their high thermal conductivity, which can range from 170 to 220 W/m·K. This makes them superior to many other ceramics for applications requiring efficient heat dissipation.

2. Excellent Electrical Insulation:Despite its good thermal conductivity, AlN maintains excellent electrical insulation properties, making it suitable for electronic packaging and semiconductor applications where dielectric strength is crucial.

3. Low Coefficient of Thermal Expansion (CTE):The CTE of aluminum nitride is relatively low and close to that of silicon (~4.5-5.0 ppm/°C). This minimizes thermal mismatch stresses when these materials are used together in electronic devices.

4. Chemical Stability:AlN ceramic rods exhibit good resistance against chemical corrosion, including resistance to molten metals and many acids and alkalis, enhancing their durability in harsh environments.

5. Mechanical Strength:They possess sufficient hardness and strength for many industrial applications, although they are brittle and can fracture under impact or excessive stress.

6. Density:The density of AlN is approximately 3.26 g/cm³, contributing to its lightweight nature compared to some other ceramic materials.

Specification of Aluminum Nitride Ceramic Rod:

| Property | Typical Specification |

| Material Composition | AlN (Aluminum Nitride) |

| Thermal Conductivity | 170-220 W/m·K |

| Coefficient of Thermal Expansion | ~4.5-5.0 ppm/°C (similar to silicon) |

| Dielectric Strength | >20 kV/mm |

| Dielectric Constant (1 MHz) | ~8.4 – 9.6 |

| Volume Resistivity | >10^14 Ω·cm at 25°C |

| Mechanical Strength (Bending) | ~350-450 MPa |

| Hardness (Vickers) | ~12-14 GPa |

| Density | ~3.26 g/cm³ |

| Porosity | <1% |

| Operating Temperature Range | -269°C to +1000°C |

| Chemical Stability | Excellent resistance to acids, alkalis, and molten metals |

| Surface Finish | Can be polished to optical quality or left with a machined finish |

| Diameter | Customizable; typically ranges from a few millimeters to several centimeters |

| Length | Customizable; commonly available in lengths up to several meters |

| Purity | High purity options available (e.g., >99%) |

Applications of Aluminum Nitride Ceramic Rod:

Electronics and Semiconductors

1. Heat Sinks and Thermal Management:AlN rods are used as heat sinks or thermal management components in power modules, LEDs, laser diodes, and RF devices. Their high thermal conductivity efficiently dissipates heat away from sensitive components.

2. Substrates and Mounting Rods:Serve as substrates or mounting rods for semiconductor devices, ensuring proper thermal and electrical performance while minimizing thermal mismatch stresses.

3. Insulating Rods:Provide electrical insulation while allowing efficient heat transfer between components in electronic assemblies.

Automotive Industry

1. Sensor Components:Protect sensors in harsh environments such as exhaust systems, fuel lines, and engine compartments. They can withstand high temperatures and corrosive conditions.

2. Ignition Systems:Utilized in ignition systems where they must endure extreme temperatures and provide reliable electrical insulation.

3. High-Temperature Seals:Act as seals in high-temperature automotive components, maintaining integrity under thermal stress.

Telecommunications

1. Microwave Devices:Employed in microwave devices like filters and resonators due to their low dielectric loss and excellent thermal stability, crucial for maintaining signal integrity at high frequencies.

2. Satellite Communication Systems:Used in satellite components because of their lightweight nature and ability to handle thermal extremes, contributing to the reliability of space-based communication equipment.

Medical Devices

1. Implants and Diagnostic Equipment:Due to biocompatibility and resistance to bodily fluids, AlN rods can be found in certain medical implants or diagnostic equipment requiring stable thermal and electrical properties.

2. Laser Surgery Tools:Used in surgical tools and equipment for laser surgery, benefiting from their thermal stability and durability.

High-Temperature Applications

1. Furnaces and Kilns:Serve as structural components, supports, or spacers in furnaces and kilns, taking advantage of their thermal stability and chemical resistance to withstand high temperatures and corrosive atmospheres.

2. Metallurgical Processes:Used in processes involving molten metals due to their resistance to chemical attack by molten materials.

Optoelectronics

1. Optical Windows and Lenses:Benefiting from their transparency in certain wavelengths and thermal stability, AlN rods can be used in optoelectronic devices like optical windows and lenses.

Laser Technology

1. Laser Components:As substrates or components in laser technology, benefiting from their thermal conductivity and mechanical strength.

Aerospace and Defense

1. Avionics and Spacecraft Components:Utilized in avionics and spacecraft components where reliable operation under extreme conditions is critical.

2. Radar Systems:Used in radar systems for their electromagnetic compatibility and thermal stability.

General Industrial Applications

1. Mechanical Seals and Bearings:AlN rods can serve as mechanical seals or bearings in machinery, providing wear resistance and thermal stability.

2. Chemical Processing:Used in chemical processing equipment due to their resistance to acids, alkalis, and other corrosive substances.

3. Vacuum Systems:Employed in vacuum systems for their excellent outgassing characteristics and thermal stability.

4. Tooling and Fixturing:Used in tooling and fixturing applications where thermal management and dimensional stability are important.

Company Profile

Advanced Ceramics founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2012, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Aluminum Nitride Ceramic Products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

FAQs of Aluminum Nitride Ceramic Rod:

Q1: What is Aluminum Nitride (AlN)?

A1: Aluminum Nitride is a ceramic material known for its excellent thermal conductivity, electrical insulation properties, and low coefficient of thermal expansion. It’s widely used in electronics, semiconductors, and other high-performance applications.

Q2: Why are AlN ceramic rods superior to other ceramics? A2: AlN ceramic rods offer higher thermal conductivity compared to materials like aluminum oxide (Al₂O₃), making them better for heat dissipation. They also provide excellent electrical insulation, chemical stability, and a CTE close to silicon, minimizing thermal mismatch stresses.

Q3: What is the typical thermal conductivity of AlN ceramic rods?

A3: The thermal conductivity of AlN ceramic rods can range from 170 to 220 W/m·K, depending on purity and manufacturing processes.

Q4: Where are AlN ceramic rods commonly used?

A4: Common applications include heat sinks, insulating spacers, substrates in power modules, LEDs, laser diodes, RF devices, automotive sensors, ignition systems, microwave devices, satellite communication systems, medical implants, diagnostic equipment, furnaces, kilns, optical windows, and laser technology components.

Q5: Can AlN ceramic rods be customized?

A5: Yes, AlN ceramic rods can often be customized in terms of diameter, length, and surface finish to meet specific application requirements.

REQUEST A QUOTE

RELATED PRODUCTS

Customized Excellent Thermal Conductivity Aluminum Nitride Component ALN Ceramic Part

Industry Electrical CNC Machining Ceramic Component Aluminum Nitride Ceramic ALN Heat Sink

Refractory Custom AlN Tubes Aluminum Nitride Ceramic Tubes

220V 380V Aluminum Nitride Ceramic Sheet AlN Heating Element Heater Plates

Cu Coating Aluminium Nitride AlN Ceramic Substrate