Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

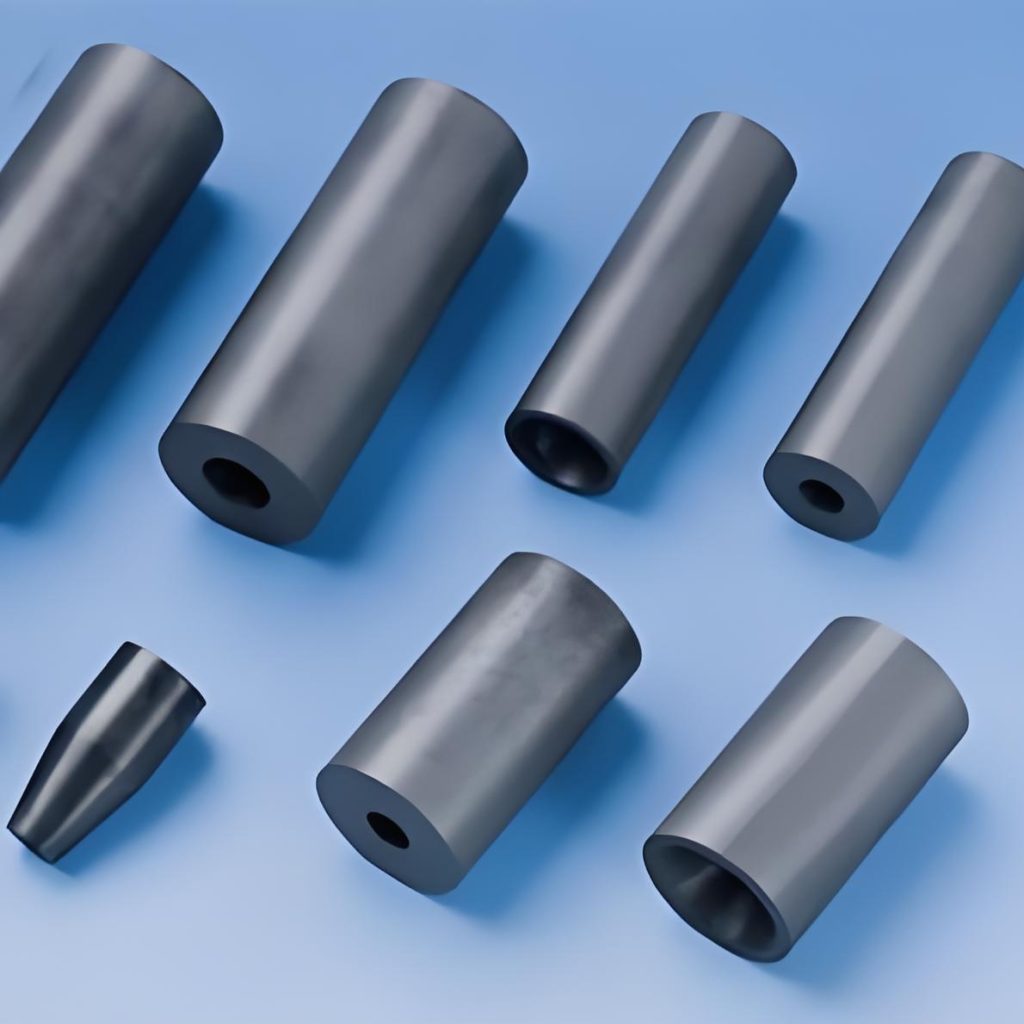

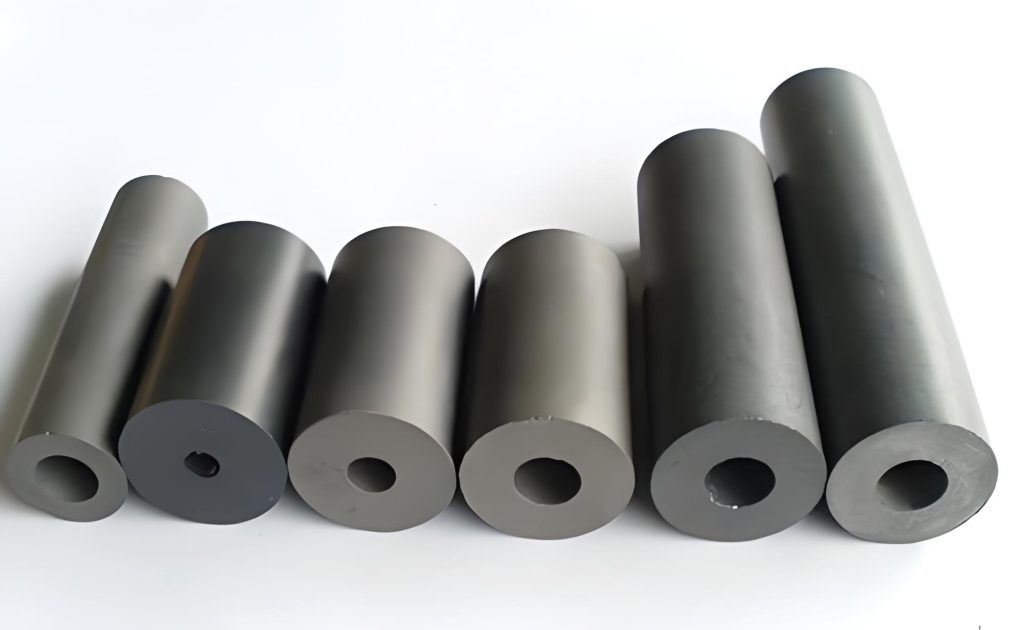

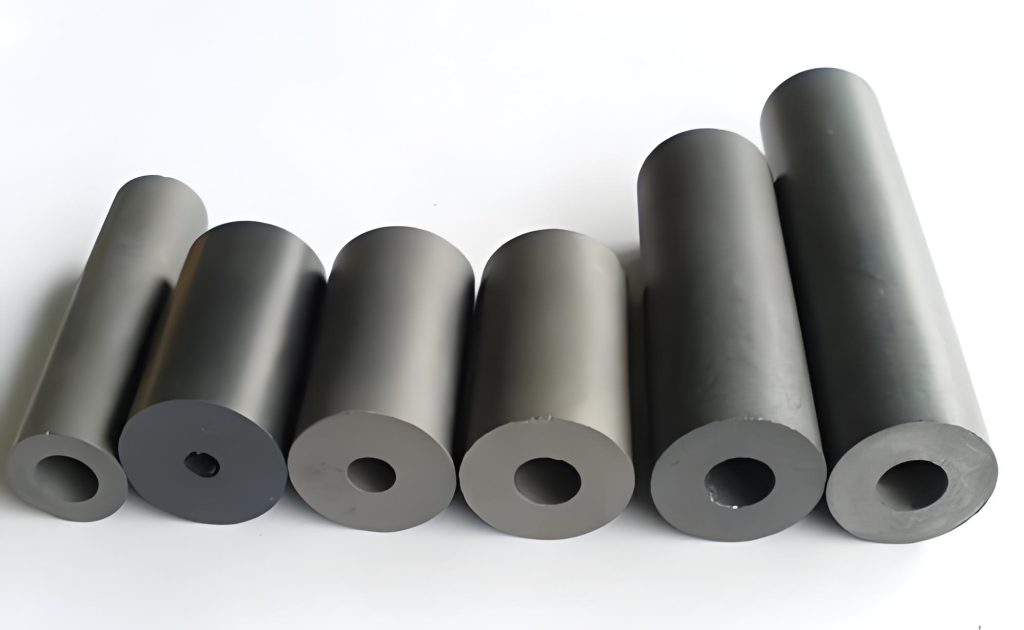

Overview of Boron Carbide Tube:

Boron carbide (B₄C) tubes are specialized ceramic components that take advantage of the excellent properties of DBC to provide superior performance in a variety of demanding applications. A detailed overview of DBC tubes, including their characteristics, manufacturing processes and key applications, is provided below.

Boron carbide tubes are cylindrical structures fabricated from boron carbide, a material known for its extreme hardness, high melting point, excellent wear resistance, and chemical stability. These tubes are used in environments where conventional materials would not suffice due to their limitations in hardness, temperature resistance, or chemical reactivity.

Features of Boron Carbide Tube:

Extremely High Hardness: Carbide tubes have a Vickers hardness of approximately 35 GPa, providing unrivaled resistance to abrasion.

High melting point: The melting point is approximately 2450°C (4442°F), allowing these tubes to withstand extremely high temperatures without significant degradation.

Low Density: Despite being very hard, carbides have a relatively low density of approximately 2.52 g/cm³, contributing to lightweight designs.

Chemical Stability: Highly resistant to most acids and alkalis, suitable for corrosive environments.

Thermal Conductivity: Moderate thermal conductivity allows for effective heat dissipation.

Electrical insulation: acts as an effective electrical insulator for electronic applications.

Nuclear Absorption: High nuclear absorption cross-sectional area makes DBC tubes valuable in nuclear applications.

Boron Carbide Tube

Specifications of Boron Carbide Tube:

| Property | Specification |

| Chemical Formula | B₄C |

| Hardness (Vickers) | ~35 GPa |

| Density | 2.52 g/cm³ |

| Melting Point | 2450°C (4442°F) |

| Thermal Conductivity | 27-129 W/m·K (depending on purity and orientation) |

| Thermal Expansion Coefficient | 6.5 × 10⁻⁶ K⁻¹ |

| Electrical Resistivity | High (acts as an electrical insulator) |

| Compressive Strength | > 3.5 GPa |

| Tensile Strength | Relatively low due to brittleness |

| Modulus of Elasticity | 460-500 GPa |

| Fracture Toughness | Low (~3 MPa·m^(1/2)) |

| Chemical Stability | Highly resistant to most acids, alkalis, and molten salts |

| Neutron Absorption Cross Section | High (~760 barns for natural boron) |

| Corrosion Resistance | Excellent in most environments |

| Acoustic Properties | Good sound damping characteristics |

| Biocompatibility | Generally considered biocompatible |

| Environmental Impact | Non-toxic; long service life reduces replacement frequency |

| Manufacturing Process | Hot isostatic pressing (HIP), sintering, reaction bonding, machining |

| Typical Dimensions | Inner diameter: varies by application; Outer diameter: varies by application |

| Wall Thickness | Customizable based on application requirements |

| Length | Can be manufactured in lengths suitable for specific applications |

Applications of Boron Carbide Tube:

1. Nuclear industry

Control rods: Fluorocarbon tubes are used as neutron absorbers in nuclear reactor control rods to regulate the fission process and ensure safe and controlled operation.

Shielding components: Used for radiation shielding, preventing neutron radiation in nuclear facilities, and strengthening safety protocols.

2. Industrial wear parts

Abrasive nozzles: Ideal for sandblasting operations due to their excellent wear resistance and longer service life than conventional materials.

Extrusion Dies: Used in the extrusion process for metals and ceramics, providing durability and material forming accuracy.

Pump linings and valves: Used in pumps and valves that handle abrasive or corrosive materials to extend service life and reduce maintenance requirements.

3. Chemical Processing

Reactor linings: Suitable for lining reactors and vessels handling aggressive chemicals, with excellent corrosion resistance at high temperatures.

Piping systems: for piping systems that require high resistance to chemical attack and high temperatures, such as petrochemical plants.

4. Aerospace and defence

Thermal protection system: Used for spacecraft reentry vehicles to prevent extreme heat generated during reentry.

Armor components: Integrated into personal and vehicle armor systems for ballistic protection, combining light weight and high hardness.

6. Automotive industry

Engine components: used for engine components requiring high wear resistance and thermal stability, such as piston rings and valve seats.

Brake pads: Some high-performance brake pads use boron carbide to improve braking performance and durability.

8. Scientific research

Experimental Reactors: Used in experimental reactors and research facilities to withstand extreme conditions.

High-Temperature Furnaces: Used in furnace linings and components that must withstand high temperatures without degradation.

9. Electronic equipment

Heat sinks: Boron carbide has moderate thermal conductivity and electrical insulation properties and is used in heat sinks for electronic equipment.

Insulating Components: Used as an insulator in a variety of electronic components to protect against electrical short circuits and overheating.

10. Oil and gas

Downhole tools: Used for downhole tools and equipment that must work under harsh conditions such as high pressure and high temperature.

Corrosion-resistant pipes: used for pipes that must resist corrosive fluids and high temperatures.

Company Profile

Advanced Ceramics founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products. Since its establishment in 2012, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

FAQs of Boron Carbide Tube

1.What are the disadvantages of boron carbide?

However, one of the disadvantages of boron carbide is that it starts to oxidize when temperatures exceed 500°C. Unlike silicon carbide, the silicon dioxide oxide layer it forms will delay high-temperature oxidation.

2.Is boron carbide harder than tungsten carbide?

Boron carbide (B4C) is the third hardest material after diamond and boron nitride. It is an expensive, low-density material. In addition, it is also very fragile.

3.Is boron carbide stronger than silicon carbide?

In addition, boron carbide is harder and lighter than other armor materials such as silicon carbide, making it ideal for protective equipment, especially bulletproof vests.

4.Is boron carbide harder than diamond?

Boron carbide is also one of the hardest compounds we know, but it is not harder than diamond and boron nitride.

5. What is the typical manufacturing process for boron carbide tubes?

Common manufacturing processes include:

Hot Isostatic Pressing (HIP): Powdered boron carbide is compacted under uniform pressure and high temperature.

Sintering: Heating powdered boron carbide below its melting point to bond particles.

Reaction Bonding: Reacting carbon with boron oxide or boric acid to form boron carbide directly within the matrix.

REQUEST A QUOTE

RELATED PRODUCTS

Eco-Friendly Boron Carbide 99.9% B4C Tetraboron Carbide Ceramic Target for Chemical Sensors

Superfine Abrasive Material Boron Carbide F400 F800 B4C Powder China Boron Carbide for Wear Resistance Boron Carbide Ceramic Rod

Black Boron Carbide Micro-powder for Manufacturing Ceramic Products

Customized Hexagon Boron Carbide Ceramic Plate B4C Ceramic Tile

Customized High Strength Hexagonal Boron Carbide Ceramic Tiles B4C Plate