Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

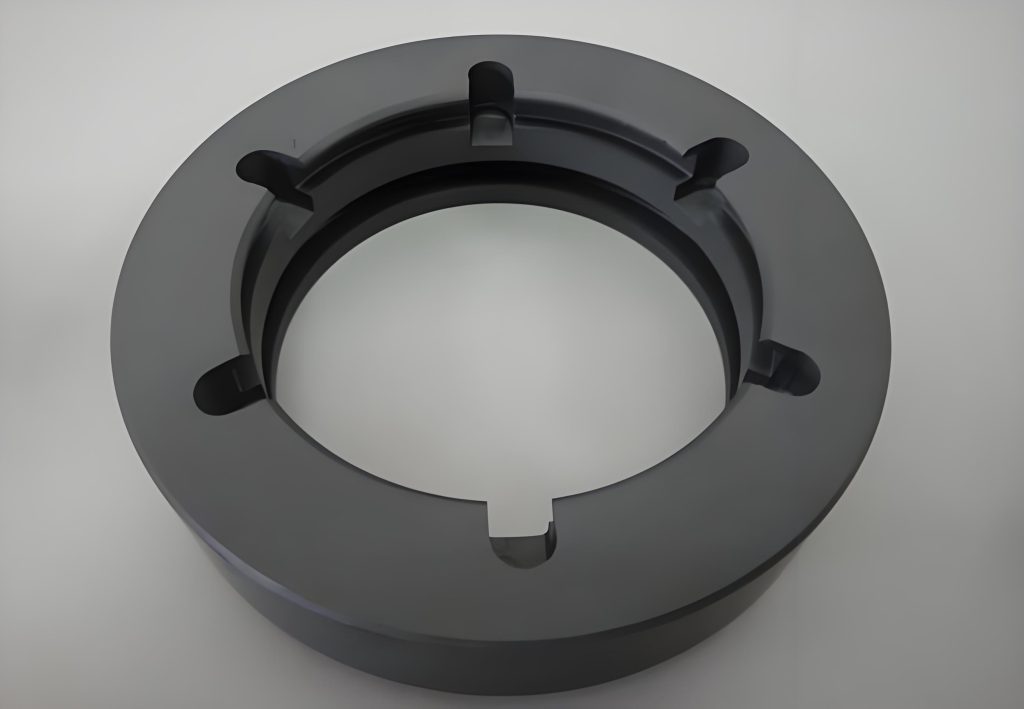

Overview of Silicon carbide ring

Silicon carbide (SiC) rings are advanced ceramic components that offer a unique combination of physical, mechanical, and thermal properties. These rings are widely used in various industries due to their exceptional performance characteristics.

Silicon Carbide SiC Ring

Features of Silicon Carbide Ring

1. High Hardness

Mohs Hardness: SiC rings have a Mohs hardness of around 9.5, making them one of the hardest materials available, second only to diamond.

Wear Resistance: This high hardness translates into excellent wear resistance, which is crucial for applications involving abrasive environments or high friction.

2. Excellent Thermal Conductivity

Thermal Conductivity: SiC rings typically have a thermal conductivity ranging from 120 to 270 W/m·K, depending on the purity and crystal structure.

Efficient Heat Dissipation: This property makes SiC rings ideal for applications where rapid heat transfer is necessary, such as in heat exchangers, heating elements, and thermal management systems.

3. Low Coefficient of Thermal Expansion

Thermal Expansion Coefficient: SiC rings have a low coefficient of thermal expansion, typically around 4.0 to 4.5 × 10^-6 /°C.

Dimensional Stability: This low expansion ensures minimal deformation under temperature changes, reducing the risk of thermal stress and cracking.

4. High-Temperature Resistance

Operating Temperature: SiC rings can withstand temperatures up to 1600°C without significant degradation of their physical or chemical properties.

Stability in Extreme Conditions: This makes them suitable for use in furnaces, kilns, and other high-temperature processes.

5. Chemical Inertness

Corrosion Resistance: SiC rings exhibit excellent resistance to most acids, bases, and salts, making them highly durable in corrosive environments.

Chemical Stability: They do not react with many chemicals, even at high temperatures, ensuring long-term performance in harsh conditions.

6. Mechanical Strength

Bending Strength: SiC rings have high flexural strength, typically ranging from 300 to 700 MPa, depending on the manufacturing process and material grade.

Tensile Strength: They also offer good tensile strength, making them resistant to mechanical stress and deformation.

7. Electrical Properties

Insulation or Semiconductivity: Depending on the type of SiC (α-SiC or β-SiC), the rings can be either excellent electrical insulators or semiconductors.

High Resistivity: For insulating applications, SiC rings have a resistivity greater than 10^12 Ω·cm, providing effective electrical isolation.

8. Thermal Shock Resistance

Rapid Temperature Changes: SiC rings can withstand rapid temperature changes without cracking or breaking, making them suitable for applications involving thermal cycling.

Durability in Dynamic Environments: This property is particularly valuable in industries like aerospace and automotive, where components are exposed to varying temperatures.

9. Lightweight

Density: SiC rings have a density of approximately 3.21 g/cm³, which is lower than many metals, making them lighter and easier to handle.

Weight Savings: Their lightweight nature is beneficial in applications where reducing structural weight is important, such as in aerospace and automotive components.

10. Self-Lubricating Properties

Low Friction: Some grades of SiC rings have a smooth surface finish and exhibit self-lubricating properties, reducing the need for additional lubricants and maintenance.

Reduced Maintenance: This feature can extend the service life of components and reduce operational costs.

11. Precision Machining

Customizable Dimensions: SiC rings can be machined to precise dimensions using diamond-coated tools, allowing for custom shapes and sizes to meet specific application requirements.

High Tolerance: They can achieve tight tolerances, making them suitable for precision engineering applications.

12. Environmental Compatibility

Non-Toxic: SiC rings are non-toxic and environmentally friendly, making them suitable for use in industries with strict environmental regulations.

Recyclable: They can be recycled, contributing to sustainable manufacturing practices.

Silicon Carbide Ring

Specifications of Silicon Carbide Ring

| Parameter | Typical Value | Unit |

| Physical Dimensions | ||

| – Inner Diameter (ID) | Customizable, standard sizes available | mm |

| – Outer Diameter (OD) | Customizable, standard sizes available | mm |

| – Thickness | 1 mm to 50 mm | mm |

| – Shape | Circular, can be customized | |

| Density | 3.21 | g/cm³ |

| Hardness | ||

| – Mohs Hardness | 9.5 | |

| – Vickers (HV) | 2500 to 3500 | kg/mm² |

| Thermal Conductivity | 120 to 270 | W/m·K |

| Coefficient of Thermal Expansion | 4.0 to 4.5 × 10^-6 /°C (20-1000°C) | /°C |

| Operating Temperature | Up to 1600°C | °C |

| Bending Strength | 300 to 700 | MPa |

| Tensile Strength | 300 to 600 | MPa |

| Chemical Resistance | Excellent resistance to most acids, bases, and salts | |

| Electrical Resistivity | > 10^12 | Ω·cm |

| Thermal Shock Resistance | Can withstand rapid temperature changes up to 1000°C | |

| Surface Finish | Rough, polished, or other treatments | |

| Porosity | Very low, typically less than 1% | % |

| Crystal Structure | α-SiC (hexagonal), β-SiC (cubic) | |

| Impurity Content | Depends on application; high-purity grades available | |

| Dimensional Tolerance | ±0.05 mm or tighter, depending on precision requirements | mm |

| Color | Typically black or dark gray |

Notes:

Customization: Many of these parameters can be customized based on specific application requirements.

High-Purity Grades: For applications in semiconductors and optoelectronics, higher purity grades with lower impurity content are available.

Special Applications: For specialized industrial uses, additional factors such as long-term stability and environmental resistance may need to be considered.

Additional Information:

Machining: Silicon carbide rings can be machined using diamond-coated tools to achieve custom shapes and sizes. Precision machining can achieve tight tolerances, making them suitable for high-precision engineering applications.

Applications: Silicon carbide rings are widely used in industries such as seals and bearings, pumps and valves, furnace components, chemical processing, aerospace, automotive, optics, and environmental technology.

Applications of Silicon Carbide Ring

Silicon carbide rings have a variety of applications due to their unique properties:

1. Mechanical Sealing Applications

Pumps: In industrial pumps, silicon carbide rings are used as seal faces. For example, in centrifugal pumps used in the chemical and petroleum industries, the silicon carbide seal rings provide excellent wear resistance and chemical stability. The high hardness of silicon carbide allows it to withstand the abrasion caused by the pumped fluid, which may contain solid particles. At the same time, its chemical resistance ensures that it can handle a wide range of corros handle a wide range of corrosive chemicals, such as acids and alkalis, without significant degradation. This helps to prevent leakage and maintain the efficiency of the pump.

Mixers and Reactors: In mixing equipment and chemical reactors, silicon carbide rings are used to seal the rotating shafts. The ability to maintain a tight seal under high-pressure and high-temperature conditions is crucial. Silicon carbide rings can operate stably in environments with pressures up to several megapascals and temperatures up to hundreds of degrees Celsius, ensuring that the reaction or mixing process is carried out in a sealed environment, preventing the escape of harmful substances or the ingress of impurities.

2. High-Temperature Furnace Applications

Support and Insulation: Silicon carbide rings can be used as support structures in high-temperature furnaces. They can support the heating elements or the workpieces being processed. Their high-temperature resistance and good thermal conductivity properties make them ideal for this purpose. For example, in a vacuum furnace used for heat-treating metal parts, silicon carbide rings can help distribute heat evenly around the workpiece, ensuring uniform heat treatment. Additionally, they can act as insulation materials to some extent, reducing heat loss to the surrounding environment.

Crucible Rings: In some high-temperature melting processes, silicon carbide rings are used as crucible accessories. They can help hold the crucible in place and also provide some protection against heat dissipation and chemical reactions between the crucible and the furnace environment. For example, in the melting of certain special alloys or ceramics, the silicon carbide ring-equipped crucible can provide a more stable melting environment.

3. Semiconductor and Electronics Applications

Wafer Processing: In semiconductor wafer processing, silicon carbide rings can be used as carriers or holders. They provide a stable and clean platform for wafer handling and processing. Their high – purity and chemical stability ensure that the wafers are not contaminated during various manufacturing steps such as etching and deposition. The good electrical insulation properties of silicon carbide also prevent electrical interference between different parts of the wafer processing equipment.

High-Power Electronic Devices: In high-power electronic components such as insulated-gate bipolar transistors (IGBTs), silicon carbide rings can be used for heat dissipation and insulation. The high – thermal – conductivity of silicon carbide helps to quickly dissipate the heat generated by the high-power device, improving its reliability and performance. At the same time, its insulating properties prevent electrical short-circuits and ensure the safe operation of the device.

4. Aerospace and Automotive Applications

Engine Components: In aerospace and automotive engines, silicon carbide rings can be used in various components. For example, in turbine engines, they can be used as part of the sealing system to reduce gas leakage and improve engine efficiency. Their lightweight and high-strength properties also contribute to the overall performance of the engine. In automotive engines, silicon carbide rings can be used in piston rings or valve seals to enhance the wear resistance and sealing performance of the engine, leading to better fuel economy and reduced emissions.

Brake Systems: In high-performance brake systems, silicon carbide rings can be used as part of the brake rotor or pad material. The high-friction and high-temperature-resistant properties of silicon carbide can provide excellent braking performance, especially in high-speed and heavy-duty braking applications. The use of silicon carbide-based brake components can reduce braking distances and improve the safety of vehicles.

Company Profile

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

FAQs of Silicon Carbide Ring

1. What is a silicon carbide ring made of?

A: A silicon carbide ring is primarily made of silicon carbide (SiC). Silicon carbide is a compound of silicon and carbon, usually synthesized through high-temperature processes. The material has a strong covalent-bonded crystal structure. Some silicon carbide rings may also have trace amounts of other elements or additives used to enhance certain properties, such as improving the sintering process or adding color.

3. What are the advantages of a silicon carbide ring over a traditional metal ring?

A: Hardness and Durability: Silicon carbide is extremely hard, second only to diamond in hardness. This makes silicon carbide rings highly resistant to scratches and abrasions. They can maintain their appearance and integrity over a long period, unlike metal rings that are more prone to scratching.

Chemical Resistance: Silicon carbide rings have excellent resistance to chemicals such as acids and alkalis. This means they are less likely to be damaged or corroded when exposed to substances like household cleaners, perfumes, or sweat, which can cause discoloration or degradation in metal rings.

Thermal Stability: With a low thermal expansion coefficient, silicon carbide rings can withstand a wide range of temperatures without significant expansion or contraction. This property is beneficial for applications where the ring may be exposed to temperature changes, such as in jewelry worn during different seasons or in industrial settings.

3. Can silicon carbide rings be resized?

A: Resizing a silicon carbide ring is generally more difficult than resizing a metal ring. Due to its high hardness and brittleness, traditional methods of stretching or cutting and adding material, as used for metal rings, are not applicable. Some manufacturers may offer limited resizing options through advanced machining techniques, but this is not as straightforward as with metal rings and may have limitations depending on the design and thickness of the ring.

4. How do you clean a silicon carbide ring?

A: To clean a silicon carbide ring, you can use a mild detergent and warm water. Gently scrub the ring with a soft-bristled brush to remove dirt and debris. Avoid using harsh chemicals or abrasive cleaners as they may scratch the surface. After cleaning, rinse thoroughly with clean water and dry with a soft, lint-free cloth.

5.Are silicon carbide rings hypoallergenic?

A: Silicon carbide rings are generally considered hypoallergenic. Since they are not made of common allergenic metals like nickel, they are less likely to cause allergic reactions. However, individual sensitivities can vary, and some people may still have a reaction to other substances that the ring may come into contact with, such as certain cleaning agents or adhesives used in the manufacturing process.

REQUEST A QUOTE

RELATED PRODUCTS

Diamond Oil Stone CBN Stick Grinding Stone Abrasive Block Silicon Carbide Ceramic Whetstone

Customization 1um 5um 15um 50um 100um Alumina Silicon Carbide Ceramic Porous Vacuum Plate

Kiln Furniture Sic Ceramic Plate Refractory Ceramic Kiln Shelf Cheap Ceramic Shelves Silicon Carbide Tiles Slabs

Engineering Ceramic Silicon Carbide Ceramic Bushing

High temperature Silicon Carbide Insulator Ceramic Sheet SiC plate for Chip IC MOS IGBT /Power Module