Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Silicon Carbide Plate

Silicon Carbide Plate (SCP), usually refers to plates made from the material Silicon Carbide (SiC). Silicon Carbide is a composite material that combines the properties of silicon and carbon and has a wide range of excellent properties for a wide range of industrial applications.

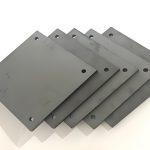

Silicon Carbide Plate

Features of Silicon Carbide Plate

Silicon Carbide Plate usually refers to a plate made of silicon carbide (SiC) material. Silicon carbide is a composite material that combines the characteristics of silicon and carbon, has many kinds of excellent properties, and is widely used in industry. The following are some of the main features of silicon carbon plate:

High hardness: Silicon carbide has a very high hardness, second only to diamond, which makes silicon carbon plates extremely wear-resistant and suitable for various environments with severe wear.

High-temperature stability: Silicon carbon plate can maintain its physical and chemical properties unchanged at very high temperatures, and the maximum operating temperature can reach more than 1600°C, so it is widely used in high-temperature industries such as metallurgy and ceramic sintering.

Low thermal expansion coefficient: Compared with metal materials, silicon carbon plates have a lower thermal expansion coefficient, which means that they change less in size when the temperature changes, reducing the risk of thermal stress and deformation.

Good thermal conductivity: Silicon carbon plate has a high thermal conductivity and can faster conduct heat, which is ok for application scenarios that require efficient heat dissipation.

Corrosion resistance: Silicon carbide has good resistance to most acids, alkalis and salts and is not easily corroded, which makes silicon carbon plates also have important applications in the chemical industry.

Electrical insulation: Although some types of silicon carbide can be semiconductors, ordinary silicon carbon plates are generally good electrical insulators and are suitable for use as insulating components in electrical equipment.

Lightweight: Compared with traditional metal materials, silicon carbon plates have a lower density, which helps to reduce the weight of the structure, which is particularly important for fields such as aerospace.

Thermal shock resistance: Silicon carbon plates can withstand large temperature changes in a short period without cracking or damage, which is very important in applications with rapid heating and cooling.

Self-lubrication: Some silicon carbide products have a smooth surface and have a certain self-lubricating effect. They can work under oil-free lubrication conditions and reduce maintenance costs.

Silicon Carbide Plate

Specifications of Silicon Carbide Plate

| Parameter | Typical Value | Unit |

| Physical Dimensions | ||

| – Thickness | 0.5 mm to 50 mm | mm |

| – Width/Length | Customizable, standard sizes like 300×300, 400×400, 600×600 | mm x mm |

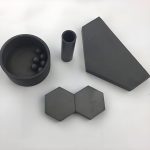

| – Shape | Rectangular, square, circular, custom | |

| Density | 2.95 to 3.20 | g/cm³ |

| Hardness | ||

| – Rockwell A (HRA) | 85 to 93 | |

| – Vickers (HV) | 2500 to 3500 | kg/mm² |

| Thermal Conductivity | 120 to 270 | W/m·K |

| Coefficient of Thermal Expansion | 4.0 to 4.5 × 10^-6 /°C (20-1000°C) | /°C |

| Bending Strength | 300 to 700 | MPa |

| Chemical Resistance | Excellent resistance to most acids, bases, and salts | |

| Electrical Resistivity | > 10^12 | Ω·cm |

| Thermal Shock Resistance | Can withstand rapid temperature changes up to 1000°C | |

| Operating Temperature | Up to 1600°C | °C |

| Surface Finish | Rough, polished, or other treatments | |

| Porosity | Very low, typically less than 1% | % |

| Crystal Structure | α-SiC (hexagonal), β-SiC (cubic) | |

| Impurity Content | Depends on application; high-purity grades available | |

| Dimensional Tolerance | ±0.05 mm or tighter, depending on precision requirements | mm |

Notes:

Customization: Many of these parameters can be customized based on specific application requirements.

High-Purity Grades: For applications in semiconductors and optoelectronics, higher purity grades with lower impurity content are available.

Special Applications: For specialized industrial uses, additional factors such as long-term stability and environmental resistance may need to be considered.

Silicon Carbide Plate

Applications of Silicon Carbide Plate

Silicon Carbide Plate has a wide range of applications in multiple industrial fields due to its excellent physical, mechanical and thermal properties. The following are some of the main application areas of silicon carbon plates and their specific uses:

1. High-temperature industry

Metallurgical industry: used to manufacture refractory materials such as furnace linings, burner nozzles, heating elements, etc., which can remain stable at extreme temperatures.

Ceramic sintering: As a support plate or a sintering plate, it is used to carry ceramic products during high-temperature sintering to ensure the stability of their shape and size.

2. Mechanical engineering

Seals: Due to its high hardness and wear resistance, it is often used to manufacture mechanical sealing rings, pump shaft seals, valve seat rings and other components, suitable for high pressure, high temperature and corrosive environments.

Bearings: Used as a material for rolling bearings or sliding bearings, it has the characteristics of low friction coefficient and long life.

Cutting tools: Used to manufacture cutting tools, grinding tools and drill bits, especially suitable for machining cemented carbide and other difficult-to-machine materials.

3. Electronics and semiconductors

Substrate materials: In power electronic devices, such as MOSFET, IGBT, etc., silicon carbon plates are used as substrate materials to provide good thermal conductivity and electrical insulation.

Heat sink: used for heat dissipation management of high-power electronic devices, such as LED lighting, lasers, microprocessors, etc., which can effectively conduct heat and maintain low-temperature operation.

4. Chemical industry

Reactor lining: Due to its excellent chemical corrosion resistance, silicon carbon plates are often used to manufacture chemical reactor linings to resist acid, alkali and salt corrosion.

Filter: used for gas and liquid filtration, especially in high-temperature and corrosive environments, such as exhaust gas treatment systems.

5. Aerospace

Structural components: The lightweight and high-strength characteristics of silicon carbon plates make them an ideal choice in the aerospace field, such as engine blades, nozzles, heat shields, etc.

Thermal protection system: used to manufacture thermal protection layers for spacecraft to protect the aircraft from high-temperature damage when re-entering the atmosphere.

6. Automotive industry

Brake pads: Brake pads made of silicon carbon composite materials have better braking performance and longer service life, especially for high-performance vehicles and racing cars.

Exhaust system: used to manufacture exhaust manifolds, catalytic converters and other components, which can withstand high temperatures and corrosive gases.

7. Optics and Photoelectricity

Optical lenses: The high hardness and good surface finish of silicon carbon plates make them suitable for manufacturing high-quality optical lenses and reflectors, such as optical components in telescopes and lasers.

Photodetectors: Used to manufacture efficient photodetectors, such as infrared sensors, ultraviolet sensors, etc., with high sensitivity and fast response.

8. Environmental Protection and Energy

Solar cells: Silicon carbon plates are used as substrate materials to manufacture high-efficiency solar cells to improve energy conversion efficiency.

Fuel cells: Used to manufacture electrodes and diaphragms for fuel cells, with good conductivity and corrosion resistance.

9. Medical equipment

X-ray windows: The high density and low X-ray absorption rate of silicon carbon plates make them ideal X-ray window materials for medical imaging equipment.

Surgical instruments: Due to their biocompatibility and high hardness, silicon carbon plates can be used to manufacture precision surgical instruments, such as orthopedic implants, dental tools, etc.

10. Military and Defense

Armor materials: The high hardness and impact resistance of silicon carbon plates make them ideal armor materials for manufacturing protective equipment such as bulletproof vests and armored vehicles.

Missile parts: used to manufacture missile nozzles, combustion chambers and other key parts, which can maintain stable performance under extreme conditions.

11. Other applications

Grinding and polishing: Silicon carbon plates can be processed into grinding tools of various shapes and sizes for precision grinding and polishing operations.

Laboratory equipment: used to manufacture parts of high-temperature experimental equipment, such as crucibles, evaporating dishes, etc., to ensure the safety and accuracy of the experimental process.

Company Profile

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

FAQs of Silicon carbide plate

1.What is a silicon carbide plate?

Answer: A silicon carbide (SiC) plate is a type of advanced ceramic material composed of silicon and carbon. It is known for its exceptional hardness, high thermal conductivity, low thermal expansion, excellent wear resistance, and chemical inertness. These properties make it suitable for a wide range of industrial applications, from high-temperature environments to precision mechanical components.

2.Is silicon carbide plate suitable for high-temperature applications?

Answer: Yes, silicon carbide plates are highly suitable for high-temperature applications. They can withstand temperatures up to 1600°C without significant degradation of their physical or chemical properties. This makes them ideal for use in furnaces, kilns, and other high-temperature processing equipment.

3.Can silicon carbide plates be machined or customized?

Answer: Yes, silicon carbide plates can be machined to custom shapes and sizes using specialized tools. Common machining processes include grinding, drilling, and cutting. However, due to the extreme hardness of SiC, machining requires diamond-coated tools and precise techniques to achieve the desired dimensions and surface finish.

4.How does silicon carbide compare to other ceramic materials?

Answer: Compared to other ceramics like alumina (Al₂O₃) and zirconia (ZrO₂), silicon carbide offers superior hardness, thermal conductivity, and wear resistance. It also has better thermal shock resistance and lower thermal expansion, making it more stable in high-temperature environments. However, SiC is generally more expensive than these materials due to its advanced properties and complex manufacturing process.

REQUEST A QUOTE

RELATED PRODUCTS

Indian ‘s Best ing Silicon Carbide Ceramic Raw Materials Widely Used Industrial Ceramics Processing Cut Moulded

Silicon Carbide SSiC Ceramic Plate/ Tiles

Ultrafine Silicon Carbide Powder Black/Green Silicon Carbide (SiC) Powder for Ceramic Manufacturing

High Quality Factory Custom Alumina PE Plate Silicon Carbide Hard PE Ceramic Plate 10×12” III&IV Armor Plate

Hot ing Cheap F4-F6000 Honeycomb Ceramic Filter Dust Removal Powder Siliconcarbide Black Silicon Carbide Powder for Blasting