Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

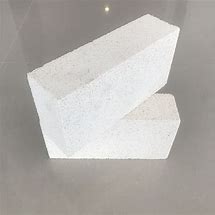

Overview of Aluminum Oxide Ceramic Refractory Bricks

Aluminum oxide (Al₂O₃), commonly known as alumina, is a versatile material used in the production of refractory bricks. These bricks are designed to withstand high temperatures and harsh environments without degrading. They are widely used in metallurgy, glass manufacturing, cement production, and other industries that require materials capable of enduring extreme conditions.

Features of Aluminum Oxide Ceramic Refractory Bricks

- High Temperature Resistance: Alumina bricks can endure very high temperatures, making them suitable for use in furnaces and kilns.

- Chemical Stability: They resist chemical attacks from acids and alkalis, which is crucial in corrosive environments.

- Low Thermal Expansion: The thermal expansion rate is relatively low, reducing the risk of cracking under thermal shock.

- Mechanical Strength: High mechanical strength allows them to support structural loads even at elevated temperatures.

- Wear Resistance: They have excellent wear resistance, extending their service life in abrasive conditions.

Specifications Table of Aluminum Oxide Ceramic Refractory Bricks

| Property | Specification Value |

|---|---|

| Al₂O₃ Content (%) | >= 90% |

| Bulk Density (g/cm³) | 2.7 – 3.6 |

| Cold Crushing Strength (MPa) | >= 80 |

| Apparent Porosity (%) | <= 20 |

| Reheat Linear Change (%) | +0.1 to -0.5 |

| Thermal Conductivity (W/m·K) | ~3.0 at 1000°C |

Applications of Aluminum Oxide Ceramic Refractory Bricks

- Steel Industry: Used in steel-making furnaces, ladles, and continuous casting nozzles.

- Glass Industry: Employed in glass melting tanks due to their ability to resist corrosion by molten glass.

- Cement Industry: Applied in rotary kilns for cement production.

- Chemical Industry: Suitable for reactors and vessels that handle corrosive chemicals.

- Petroleum Industry: Utilized in petroleum refining processes where high temperatures are common.

Production Method of Aluminum Oxide Ceramic Refractory Bricks

- Raw Material Preparation: Selection and processing of raw materials such as bauxite or calcined alumina.

- Mixing: Blending the raw materials with binders and additives to form a homogeneous mixture.

- Molding: Pressing the mixture into brick shapes using hydraulic presses or extrusion techniques.

- Drying: Removing moisture from the green bodies through drying processes.

- Firing: Heating the dried bricks to high temperatures in kilns to sinter the particles together, forming a solid structure.

- Quality Control: Inspecting the finished products for defects and ensuring they meet specifications.

Company Profile

Advanced Ceramics founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2012, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Aluminum Nitride Ceramic Products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs about Aluminum Oxide Ceramic Refractory Bricks

- Q: What are the main advantages of using aluminum oxide refractory bricks? A: They offer superior temperature resistance, chemical stability, low thermal expansion, and good mechanical strength.

- Q: Can these bricks be used in all types of industrial furnaces? A: While they are highly versatile, specific applications depend on the operating conditions and requirements of the furnace.

- Q: How do you install these bricks? A: Installation should be done by professionals who understand the thermal expansion properties and joint sealing methods.

- Q: What is the expected lifespan of these bricks? A: Lifespan varies depending on the application and maintenance but can range from several months to years.

- Q: Are there different grades of aluminum oxide bricks available? A: Yes, grades vary based on the percentage of aluminum oxide content, which affects performance characteristics.

REQUEST A QUOTE

RELATED PRODUCTS

High Purity Alumina Ceramic Rods Favorable Industrial Ceramic Application

High Purity Aluminum Oxide Al2O3 Alumina Ceramic Plate / Alumina Wear Lining Tile

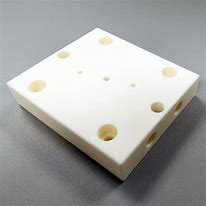

Customized Square Alumina Ceramic Plate Refractory Aluminum Oxide with Melting Crucible Premium Quality Spares Parts

High Quality 99% Alumina Ceramic Plate Al2o3 Ceramic Sheet Thin Plate

17%-19% AL2O3 Inert Alumina Ceramic Ball for Chemical Industry