Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

With boron carbideunparalleled combination of hardness (9.3 Mohs), neutron absorption capacity (600 barns), and thermal stability (2,350°C melting point), this boron carbide formula (B4C) is now at the heart of trillion-dollar industries—from nuclear reactors to electric vehicle armor.

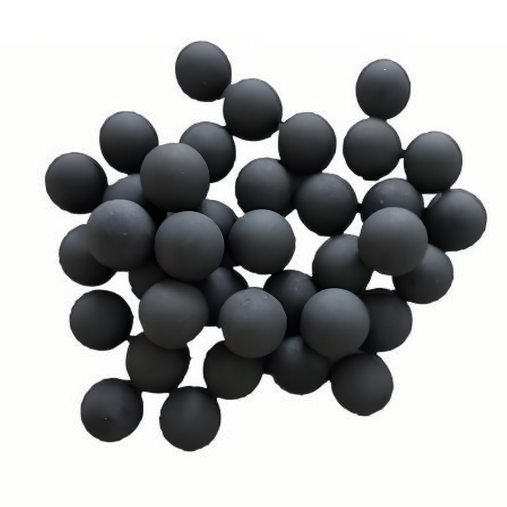

Boron Carbide

The boron carbide formula (B4C) is revolutionizing armor systems in an era of asymmetric warfare. A single B4C boron carbide plate can stop 7.62mm armor-piercing rounds at half the weight of steel, making it indispensable for next-gen military vehicles. The U.S. Department of Defense recently tripled B4C procurement contracts to $890 million annually. At the same time, China’s hypersonic missile program requires boron carbide-radome components capable of withstanding 3,000°C plasma streams—a demand spike causing B4C prices to surge 68% since 2023.

Nuclear energy’s renaissance has turned B4C boron carbide into the ultimate geopolitical chess piece. With 63 new reactors under construction globally, boron carbide’s neutron absorption cross-section (3,800 m²/g) makes it irreplaceable for control rods and shielding. Russia’s Rosatom now stockpiles B4C pellets equivalent to 15 years’ production, while South Korea’s KEPCO scrambles to secure B4C supply chains amid China’s export controls on boron raw materials.

The EV battery arms race is unlocking radical new applications for the boron carbide formula (B4C). Tesla’s patented B4C-reinforced silicon anode boosts lithium-ion battery energy density by 40%—a breakthrough enabling 500-mile charges in 12 minutes. This innovation alone could propel the B4C market to $4.2 billion by 2028, with CATL and LG Chem battling to lock down high-purity boron carbide supplies through 2035.

Advanced manufacturing breakthroughs are pushing B4C boron carbide performance to quantum leaps. German lab Fraunhofer IKTS recently achieved 99.999% pure B4C nanopowder via laser pyrolysis, enabling armor 300% tougher than conventional grades. Meanwhile, Japan’s TPR method produces boron carbide formula (B4C) components with zero porosity—critical for satellite components surviving extreme orbital thermal shocks.

Supply chain chaos is reshaping B4C trade dynamics. Turkey’s stranglehold on 72% of global borate reserves gives it kingmaker status in boron carbide production. In response, the EU launched Project CRITICAL-RAW to develop alternative B4C synthesis from seawater boron—a moonshot aiming to slash dependence from 89% to 45% by 2030.

Environmental regulations are sparking a B4C production revolution. California’s SB-54 law mandating 100% recyclable EV batteries by 2035 has ignited demand for recoverable B4C components. Swedish startup Carbodeon now reclaims 98% pure B4C from spent battery anodes using plasma arc tech—a process cutting CO2 emissions by 80% versus virgin material production.

The semiconductor industry’s AI-driven expansion is consuming B4C at alarming rates.TSMC’s 2nm chip fabs require boron carbide-coated wafer handlers resistant to fluorine plasma corrosion—a niche application swallowing 15% of global B4C output. With chipmakers stockpiling 18-month B4C inventories, smaller manufacturers face existential supply risks.

Counterfeit B4C boron carbide has triggered an international materials integrity crisis. Over 23% of B4C armor plates sold in Middle Eastern markets failed NATO STANAG 4569 tests due to graphite contamination. In response, Lockheed Martin now employs blockchain-tracked B4C batches with isotopic fingerprinting—a $120 million system ensuring bulletproof reliability.

As climate disasters multiply, the boron carbide formula (B4C) emerges as a climate resilience linchpin. B4C-reinforced concrete withstands hurricane-force debris impacts, while B4C-coated power lines prevent wildfire-sparking arcs. California’s PG&E is deploying 8,000 miles of B4C-enhanced grid infrastructure—a $2.7 billion bet against climate chaos.

The future belongs to those mastering B4C’s quantum potential. From boron carbide-based quantum dot sensors detecting single neutrons to B4C-graphene heterostructures enabling room-temperature superconductivity, this supermaterial’s journey has just begun. But with China controlling 58% of B4C production capacity and export licenses tightening, Western industries face a stark choice: innovate domestic supply chains or risk technological subjugation.

Supplier

If you are looking for Boron Carbide, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com)

Tags:b4c boron carbide,b4c,boron carbide formula