Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Long Service Life Materials Made of Ceramics 95 99 Al2o3 Insulator Alumina Ceramic Ring)

Specifications of Long Service Life Materials Made of Ceramics 95 99 Al2o3 Insulator Alumina Ceramic Ring

The Long Life Span Ceramics 95-99 Al2O3 Insulator Alumina Ceramic Ring is constructed for high-performance applications. The product has 95% to 99% light weight aluminum oxide (Al2O3), ensuring top-tier toughness. This ceramic ring resists severe heat, wear, and chemical damage. It works well in rough environments where metals or plastics fall short.

The alumina ceramic has a high melting point. It takes care of temperatures over 1600 ° C without losing shape or strength. This makes it excellent for heaters, engines, and high-heat commercial systems. The product also shields electrical energy effectively. It stops existing leakage in power systems, electronic devices, and electric components.

Mechanical stamina is an essential feature. The ceramic ring withstands hefty stress and effect. Its solidity matches sophisticated engineering materials, lowering scrapes and wear. This prolongs its life-span in relocating parts like pumps, shutoffs, and bearings.

Chemical stability is an additional benefit. The ring does not react with acids, antacid, or corrosive compounds. It does reliably in chemical processing, oil and gas devices, or laboratories. The surface stays smooth, preventing contamination or product build-up.

Industries like electronics, automotive, aerospace, and medical gadgets utilize this ceramic ring. Usual applications include spark plugs, sensing units, reducing devices, and shielding parts. Its precision making makes sure tight resistances for complex equipment.

Custom sizes and shapes are offered. The ring can be polished, coated, or machined to fulfill certain requirements. This adaptability suits personalized design tasks.

The item fulfills global quality requirements. It undertakes strict testing for thickness, pureness, and efficiency. This assures uniformity and reliability in every batch.

Low upkeep is a benefit. The ceramic ring does not require regular replacement. It reduces downtime and expenses in industrial operations.

The product is environmentally secure. It does not break down under UV direct exposure, wetness, or temperature level changes. This makes it ideal for outside or variable-condition use.

Lengthy service life and cost performance make it a preferred choice. The alumina ceramic ring delivers enduring performance under tension, warm, and chemical direct exposure.

(Long Service Life Materials Made of Ceramics 95 99 Al2o3 Insulator Alumina Ceramic Ring)

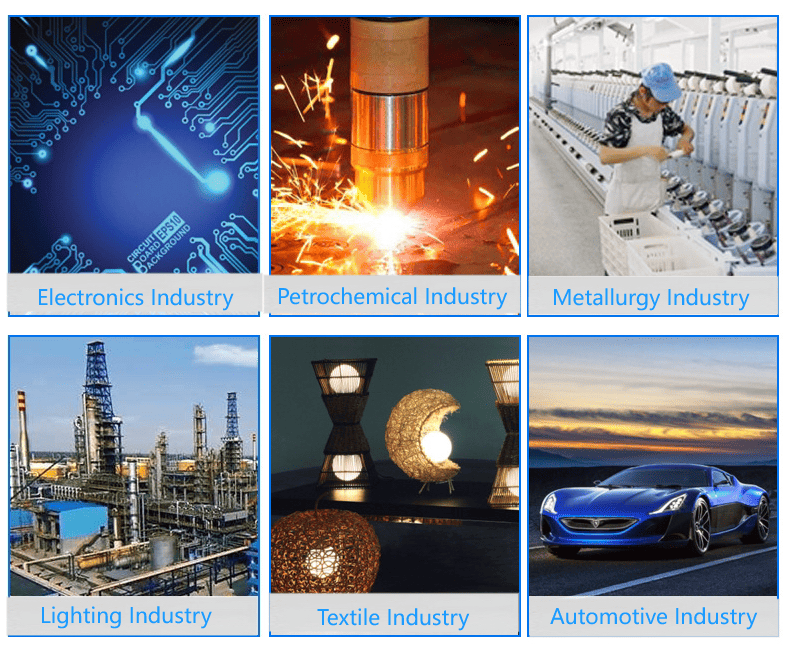

Applications of Long Service Life Materials Made of Ceramics 95 99 Al2o3 Insulator Alumina Ceramic Ring

Lengthy life span products constructed from porcelains 95-99 Al2O3 insulator alumina ceramic rings are commonly utilized across sectors. These parts take care of severe conditions as a result of high mechanical toughness, thermal security, and electrical insulation. Electronic devices makers use them in circuit breakers, sensors, and ports. Their resistance to wear and heat guarantees trusted efficiency in high-voltage environments.

Industrial machinery counts on alumina ceramic rings for sealing and insulation in pumps, valves, and bearings. The product’s firmness decreases friction, extending equipment life expectancy. They additionally protect against deterioration in chemical handling systems, keeping functional security.

Clinical tools gain from the non-reactive nature of alumina porcelains. They act as insulators in imaging gadgets and medical devices. Their biocompatibility makes them suitable for implants, lessening danger of damaging reactions.

Aerospace applications demand materials that hold up against rapid temperature adjustments and mechanical tension. Alumina ceramic rings work in engine components, sensing units, and interaction systems. Their lightweight properties contribute to fuel performance without jeopardizing durability.

The power field makes use of these porcelains in power generation and transmission. They shield high-temperature activators and generator systems. Solar and wind power systems utilize them to shield electrical components from environmental damages.

Alumina ceramic rings are economical with time. Their long service life minimizes replacement regularity and downtime. Maintenance prices go down because of resistance to destruction under severe problems.

Customizable sizes and shapes enable combination into customized tools. Accuracy production makes sure tight tolerances for constant efficiency. Surface therapies can enhance particular properties like hydrophobicity or conductivity based on application requirements.

These porcelains are eco secure. They stand up to UV radiation, moisture, and chemical direct exposure. This makes them excellent for outdoor setups or harsh commercial setups.

Efficiency consistency is critical in automation and robotics. Alumina ceramic rings supply reliable insulation and structural support in robotic arms and automated machinery. Their security ensures precision in repetitive jobs.

Product purity (95-99% Al2O3) assures minimal pollutants. This boosts electric insulation and thermal conductivity. High-density fabrication protects against gas or fluid permeation, preserving stability in pressurized systems.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Long Service Life Materials Made of Ceramics 95 99 Al2o3 Insulator Alumina Ceramic Ring

What makes ceramics like 95% and 99% Al2O3 insulators last long? These materials are built to handle tough conditions. High alumina content (95% or 99%) gives them strong hardness and resistance to wear. They don’t corrode easily when exposed to chemicals or high heat. Proper manufacturing ensures fewer defects, which helps avoid cracks or breaks over time. Correct installation and avoiding extreme stress also play a role in extending their life.

Can these ceramic rings handle high temperatures? Yes. Alumina ceramics work well in temperatures up to 1800°C. They keep their shape and strength even under intense heat. This makes them better than many metals or plastics, which might melt or weaken. Sudden temperature changes should still be avoided to prevent cracks.

Why pick alumina ceramics over metal or plastic insulators? Alumina ceramics are harder and more wear-resistant than most metals. They don’t conduct electricity, making them safer for electrical uses. Unlike plastics, they won’t soften or break down in high heat. They also resist chemicals better than many alternatives, reducing damage over time.

Where are these ceramic rings commonly used? They’re found in industrial machines, electrical systems, and high-temperature equipment. Examples include furnace parts, spark plug insulators, and protective sleeves for sensors. They’re also used in harsh environments like chemical plants or power stations where materials face extreme heat or corrosion.

How should alumina ceramic rings be maintained? Little maintenance is needed. Keep them clean from dirt or debris that might cause abrasion. Avoid hitting them with hard objects to prevent chipping. Check for cracks or wear during routine equipment inspections. Replace rings if damage is visible to ensure safety and performance.

(Long Service Life Materials Made of Ceramics 95 99 Al2o3 Insulator Alumina Ceramic Ring)

REQUEST A QUOTE

RELATED PRODUCTS

Al2O3 Ceramic HIgh Temperature Thermal Alumina Ceramic Crucible For Sale

Al2O3 Ceramic Large size aluminium oxide ceramic plates and discs Alumina ceramic round plate

Customization Industrial Insulation High Precision High Purity Ceramics 95% 99% 99.5% Structural Parts Alumina Ceramic

Industrial Electrical Technical Machinery Custom High Heat Resistant Ceramics Alumina Structural Parts

Fine Ceramic 99% Alumina Ceramic Tube