Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Silicon Nitride Ceramics

Silicon Nitride Ceramics are high-performance materials known for their excellent mechanical properties, including strength, toughness, and resistance to wear, corrosion, and thermal shock, making them ideal for demanding applications in various industries.

Features of Silicon Nitride Ceramics

Exceptional hardness and wear resistance.

Superior mechanical strength and fracture toughness.

Excellent thermal stability and resistance to thermal shock.

High corrosion resistance in aggressive environments.

Low density contributing to lightweight components.

(Factory Direct 1.4mm-1.6mm Industrial Ceramic Beads Si3n4 Silicon Nitride Ceramic Parts Zirconia Ceramic Rod And Ball)

Specifications of Factory Direct 1.4mm-1.6mm Industrial Ceramic Beads Si3n4 Silicon Nitride Ceramic Parts Zirconia Ceramic Rod And Ball

Factory Straight 1.4mm-1.6 mm Industrial Porcelain Beans Si3N4 Silicon Nitride Porcelain Parts Zirconia Porcelain Pole and Ball are created for high-performance commercial applications. These elements are made from sophisticated ceramic products, making sure durability and integrity in severe conditions. The main materials consist of silicon nitride (Si3N4) and zirconia (ZrO2), understood for their phenomenal mechanical strength and resistance to wear, warmth, and deterioration.

The ceramic beads step 1.4 mm to 1.6 mm in diameter, ideal for precision applications requiring tiny, uniform parts. Silicon nitride components give exceptional thermal stability, maintaining efficiency in temperatures approximately 1200 ° C. Zirconia ceramic poles and balls use high fracture toughness, decreasing the danger of damaging or breaking under heavy stress and anxiety. Both products exhibit reduced thermal expansion, guaranteeing dimensional security in varying temperature levels.

These products are suitable for usage in machinery, vehicle systems, aerospace devices, and chemical processing plants. They function successfully as bearings, valves, reducing devices, and wear-resistant parts. The non-reactive nature of silicon nitride and zirconia makes them compatible with hostile chemicals and high-pressure environments.

Key advantages consist of extended life span, reduced upkeep costs, and enhanced operational performance. The smooth surface finish of the beads decreases rubbing, boosting energy effectiveness in relocating parts. Zirconia’s high thickness and hardness provide premium load-bearing ability, while silicon nitride’s light-weight residential properties minimize element weight without sacrificing stamina.

Production processes entail accuracy molding and sintering to attain limited tolerances and regular quality. Each component goes through rigorous testing for solidity, density, and thermal shock resistance. Personalized sizes and shapes are available to meet certain industrial demands.

These ceramic parts are alternatives to standard steel components, offering far better efficiency in high-wear, high-temperature situations. They are electrically insulating, making them suitable for digital and semiconductor applications. Minimal lubrication is required, minimizing contamination threats in delicate atmospheres.

The mix of silicon nitride and zirconia makes certain convenience throughout sectors. Their resistance to oxidation and chemical destruction prevents early failure. Businesses benefit from lowered downtime and raised efficiency as a result of the reliability of these advanced ceramic remedies.

(Factory Direct 1.4mm-1.6mm Industrial Ceramic Beads Si3n4 Silicon Nitride Ceramic Parts Zirconia Ceramic Rod And Ball)

Applications of Factory Direct 1.4mm-1.6mm Industrial Ceramic Beads Si3n4 Silicon Nitride Ceramic Parts Zirconia Ceramic Rod And Ball

Factory Straight 1.4mm-1.6 mm Industrial Porcelain Beads Si3N4 Silicon Nitride Ceramic Components Zirconia Porcelain Rod And Sphere offer important roles throughout markets. These elements deal with extreme problems because of their warmth resistance, use resistance, and chemical security. Automotive systems utilize them in engine parts, bearings, and shutoffs. Their toughness reduces rubbing and expands devices life under heats.

Aerospace applications count on these porcelains for wind turbine blades and structural components. Silicon nitride and zirconia hold up against intense stress and thermal shock. This makes sure integrity in engines and navigation systems. Equipment manufacturing usages ceramic beads and rods in precision tools. They keep precision in grinding and reducing procedures. Their firmness prevents contortion during heavy operations.

Electronics gain from ceramic balls in semiconductors and protecting parts. The materials’ electric insulation buildings protect against existing leak. This sustains stable performance in circuit card and sensors. Chemical processing tools uses zirconia rods and beads for corrosion resistance. They sustain aggressive acids and alkalis without degrading. This reduces downtime in reactors and piping systems.

Clinical gadgets include these ceramics for implants and surgical devices. Their biocompatibility and resistance to sterilization methods make them secure for long-term usage. Renewable resource systems use ceramic parts in wind turbines and photovoltaic panels. They take care of ecological stress and anxiety while keeping effectiveness.

These items are offered in precise sizes like 1.4mm-1.6 mm beads for specialized jobs. Custom shapes ensure compatibility with industrial equipment. Manufacturing facilities focus on tight resistances to fulfill strict quality requirements. The ceramics’ light-weight nature decreases energy usage in relocating components. This contributes to cost financial savings and ecological objectives.

Industries pick silicon nitride and zirconia for their equilibrium of toughness and convenience. They change traditional metals in high-wear situations. This change enhances performance and decreases upkeep needs.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Factory Direct 1.4mm-1.6mm Industrial Ceramic Beads Si3n4 Silicon Nitride Ceramic Parts Zirconia Ceramic Rod And Ball

What are the main benefits of using silicon nitride and zirconia ceramic parts?

These parts handle extreme heat and wear better than metals. Silicon nitride resists thermal shock and lasts longer under stress. Zirconia offers high toughness and low friction. Both materials work in harsh environments without corroding. They reduce downtime and maintenance costs.

Where are these ceramic beads and rods commonly used?

They fit industries needing durable components. Examples include automotive engines, aerospace bearings, chemical pumps, and electronics. The beads work as grinding media or valve parts. Rods and balls serve in precision machinery. Their reliability suits high-performance applications.

What sizes are available for the ceramic beads?

The standard range covers 1.4mm to 1.6mm diameters. Custom sizes outside this range can be made. Exact dimensions ensure consistency for industrial equipment. Tight tolerances meet specific engineering needs.

Can these parts be customized for unique applications?

Yes. Shapes, sizes, and surface finishes are adjustable. Special coatings or treatments improve performance. Technical specs like hardness or density are tailored. Provide details for a solution matching your requirements.

How does pricing compare to traditional metal components?

Initial costs are higher. Long-term savings come from reduced replacements and repairs. Bulk orders lower per-unit prices. Contact for quotes based on quantity and customization. Competitive rates ensure value for industrial buyers.

(Factory Direct 1.4mm-1.6mm Industrial Ceramic Beads Si3n4 Silicon Nitride Ceramic Parts Zirconia Ceramic Rod And Ball)

REQUEST A QUOTE

RELATED PRODUCTS

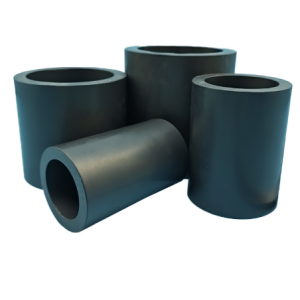

Precision CNC Machining Grey Black Silicon Nitride Si3n4 Ceramic Tube Sleeve Insert Customized

Factory Customized High Hardness Silicon Nitride Si3N4 Ceramic Blade SiN4 Plate

Custom Good Heat Dissipation Chemical Stability Silicon Nitride Si3N4 Ceramic Part Raw Material Tube Sleeve

Silicon Nitride Nozzles High Hardness And High Strength Si3N4 Nozzles

Silicon Nitride Tube High Hardness And High Strength Si3N4 Tube