Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Boron Nitride Ceramic

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Boron Nitride Ceramic

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

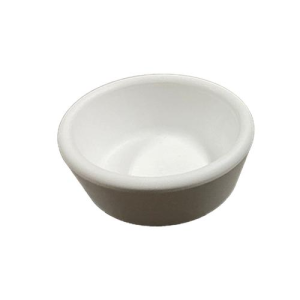

(High Purity BN Ceramic Boron Nitride Crucible for Melting)

Specification of High Purity BN Ceramic Boron Nitride Crucible for Melting

The High Purity BN Ceramic Boron Nitride Crucible is created for high-temperature melting applications. It is made from premium boron nitride ceramic with a pureness level surpassing 99%. This lessens contamination during procedures including metals, alloys, or semiconductors. The material framework is thick and consistent, making certain constant performance under extreme problems.

The crucible deals with temperature levels up to 2000 ° C in inert or vacuum settings. It stands up to thermal shock effectively. Fast heating or air conditioning does not trigger breaking or contorting. This makes it dependable for repeated usage in laboratories or commercial settings. The low thermal expansion coefficient maintains shape and dimensions also under unexpected temperature level modifications.

Chemical inertness is a crucial function. The crucible does not respond with a lot of liquified metals, consisting of gold, silver, and light weight aluminum. It holds up against destructive substances like acids, alkalis, and fluxes. This prolongs service life and preserves example honesty. The non-wetting surface protects against material attachment, streamlining cleanup after melting.

Electric insulation homes are exceptional. Boron nitride stays non-conductive at high temperatures. This suits applications calling for controlled electric settings. The material additionally supplies great machinability. Personalized dimensions or shapes can be created to satisfy details heater or process requirements.

Readily available diameters range from 20 mm to 300 mm, with wall surface thicknesses customized for optimal warmth transfer. Surface area coatings are smooth to lower contamination dangers. The crucible works with induction home heating, resistance heating, and various other melting techniques.

Customers benefit from minimized downtime as a result of the product’s durability. Maintenance demands are minimal. Prices linked to frequent replacements drop dramatically. Industries like metallurgy, electronics, and aerospace rely upon this crucible for precision melting tasks. Efficiency stays secure throughout long operational periods.

(High Purity BN Ceramic Boron Nitride Crucible for Melting)

Applications of High Purity BN Ceramic Boron Nitride Crucible for Melting

High purity BN ceramic boron nitride crucibles are essential tools in high-temperature commercial processes. These crucibles take care of severe problems. They work well in melting steels, semiconductors, and specialty products. Their special buildings make them suitable for requiring applications.

Steel melting take advantage of BN crucibles. They withstand temperatures over 2000 ° C without cracking. This makes them suitable for melting precious metals like gold or platinum. Reactive steels such as aluminum or titanium melt successfully in these crucibles. Contamination threats remain reduced because boron nitride withstands chain reactions.

Semiconductor producing counts on BN crucibles. They offer a secure environment for processing silicon, gallium arsenide, and various other compounds. The crucibles protect against contaminations from getting in delicate products. This makes sure high-purity final result. Their thermal conductivity assists manage heat circulation during crystal growth.

High-purity porcelains production utilizes these crucibles. Materials like zirconia or alumina call for consistent home heating. BN crucibles maintain uniform temperatures. They additionally resist sticking, making material removal less complicated after melting. This lowers waste and improves effectiveness.

Chemical synthesis applications rely on BN crucibles. They take care of destructive compounds like liquified salts or acids. The product’s inert nature prevents undesirable reactions. Researchers utilize them for creating sophisticated materials under controlled problems.

Aerospace and power markets utilize BN crucibles. They melt products for generator blades or solar cell elements. The crucibles’ durability sustains repeated use in extreme settings. Their reduced thermal development protects against contorting throughout rapid temperature modifications.

Lab environments like BN crucibles for precision work. They provide integrity in experiments entailing extreme heat. Their non-wetting surface maintains melted products pure. This is crucial for precise study outcomes.

BN crucibles surpass typical choices like graphite or quartz. They last longer under similar conditions. Upkeep prices remain reduced due to their resistance to wear. Industries save cash with time by decreasing replacement regularity.

These crucibles adjust to numerous heater types. They operate in vacuum cleaner or inert gas settings. This versatility sustains diverse commercial demands. Their light-weight design simplifies taking care of compared to heavier options.

High pureness BN ceramic crucibles meet strict top quality requirements. They fit applications where precision and dependability issue. Their function in sophisticated production and research continues to grow as modern technology demands greater efficiency materials.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity BN Ceramic Boron Nitride Crucible for Melting

What is a high purity BN ceramic boron nitride crucible used for?

These crucibles melt metals, alloys, and other high-temperature materials. They work in vacuum or inert gas environments. The material resists extreme heat and chemical reactions. It keeps melted substances pure without contamination.

Why choose boron nitride over other ceramics?

Boron nitride handles sudden temperature changes better. It does not crack under rapid heating or cooling. It has low thermal expansion. This reduces stress during heating. It also releases molds easily after melting.

What temperatures can BN crucibles withstand?

They operate up to 2000°C in inert atmospheres. In air, they work safely up to 900°C. Higher temperatures in air cause oxidation. The crucible’s structure stays stable under continuous high heat.

How long does a BN crucible last?

Lifespan depends on usage conditions. Proper care extends service time. Avoid mechanical shock or thermal abuse. Clean residues after each use. With good handling, it lasts many cycles.

Are BN crucibles compatible with all materials?

They work with most metals, semiconductors, and glass. They resist corrosion from molten salts and acids. Avoid using them with strong alkaline substances. Check chemical compatibility charts for specific materials.

(High Purity BN Ceramic Boron Nitride Crucible for Melting)

REQUEST A QUOTE

RELATED PRODUCTS

Customized Industrial High Purity High Temperature Boron Nitride Ceramic Tube

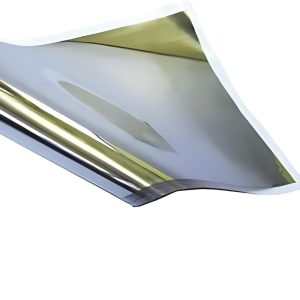

High Purity BN Insulating Ceramic Plate Boron Nitride Sheet

High Temperature BN Composite Boron Nitride Ceramic Crucible Part

High Working Temperature Corrosion Resistance Boron Nitride Gasket

High temperature high purity 99% BN boron nitride crucible