Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Boron Nitride Ceramic

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Boron Nitride Ceramic

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

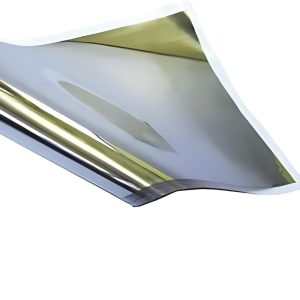

(Hot Press Boron Nitride Ceramic Sheet Pyrolytic Boron Nitride PBN Plate / Substrate / Wafer)

Specification of Hot Press Boron Nitride Ceramic Sheet Pyrolytic Boron Nitride PBN Plate / Substrate / Wafer

The Hot Press Boron Nitride Porcelain Sheet is a high-performance product made for demanding industrial applications. It integrates pyrolytic boron nitride (PBN) innovation with advanced hot-press production. This leads to an item with outstanding thermal stability, chemical resistance, and electrical insulation. The product deals with extreme temperature levels as much as 2000 ° C in inert ambiences. It maintains architectural honesty even under rapid thermal cycling. Its reduced thermal growth coefficient avoids fracturing or contorting throughout temperature changes.

The ceramic sheet offers solid resistance to thaw steels, salts, and destructive gases. This makes it suitable for settings calling for chemical inertness. Its non-reactive surface area stays clear of contamination in high-purity processes. The product offers superb electrical insulation at high temperatures. It has a dielectric strength exceeding 10 kV/mm. This makes certain dependable performance in digital and electric systems.

Mechanical properties consist of high firmness and use resistance. The sheet sustains heavy lots without contortion. It functions well in mechanical systems requiring toughness under anxiety. The surface is smooth and simple to equipment. This enables exact reducing or shaping for custom applications. Very little porosity makes certain consistent performance in vacuum cleaner settings.

Applications extend semiconductor manufacturing, metallurgy, and aerospace. The product serves as crucibles, insulators, or diffusion barriers in crystal development systems. It is made use of in CVD reactors, LED production, and high-temperature heating systems. Its thermal conductivity successfully dissipates warm in electronic gadgets. This prevents getting too hot in power electronic devices or RF elements.

The PBN plate is available in thicknesses from 0.5 mm to 50mm. Customized shapes and sizes are possible through precision machining. It meets rigorous sector standards for pureness and performance. The material is compatible with ultra-high vacuum systems. It runs reliably in harsh conditions where other porcelains fall short.

(Hot Press Boron Nitride Ceramic Sheet Pyrolytic Boron Nitride PBN Plate / Substrate / Wafer)

Applications of Hot Press Boron Nitride Ceramic Sheet Pyrolytic Boron Nitride PBN Plate / Substrate / Wafer

Warm press boron nitride ceramic sheets and pyrolytic boron nitride (PBN) plates/substrates/wafers are advanced products created for demanding commercial applications. These items excel in high-temperature atmospheres, corrosive problems, and accuracy manufacturing processes. They are commonly made use of because they provide extraordinary thermal stability, electrical insulation, and chemical resistance.

In semiconductor production, PBN layers act as crucibles for expanding gallium arsenide and gallium nitride crystals. The material’s pureness prevents contamination throughout high-temperature processes. It additionally holds up against fast temperature level modifications without fracturing. This makes PBN perfect for molecular beam epitaxy (MBE) systems, where uniform heating and ultra-high vacuum conditions are important.

Hot-pressed boron nitride sheets are common in electronic elements. They function as protecting layers in high-power gadgets, minimizing warmth build-up. Their low dielectric loss guarantees minimal signal disturbance in RF and microwave applications. These sheets also work as substratums for published circuit card in severe atmospheres, maintaining efficiency under extreme heat or radiation.

Aerospace and metallurgical sectors depend on boron nitride ceramics for heater cellular linings and protective finishings. The product resists molten steels and slag, prolonging equipment lifespan. It is likewise machined right into parts like washers and nozzles, offering longevity in rough or high-stress settings.

In optoelectronics, PBN wafers sustain the deposition of thin-film materials for LEDs and laser diodes. Their smooth surface and thermal conductivity make it possible for precise layer development. Study labs utilize PBN substrates for experimental setups including graphene or other 2D products, leveraging their inertness and thermal management homes.

Adjustable shapes and sizes permit these boron nitride products to fit specialized tools. They are readily available as poles, tubes, or facility geometries. This flexibility guarantees compatibility with diverse commercial needs. The mix of mechanical strength, thermal performance, and chemical inertness makes these products vital across innovative manufacturing fields.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Hot Press Boron Nitride Ceramic Sheet Pyrolytic Boron Nitride PBN Plate / Substrate / Wafer

What is Hot Press Boron Nitride Ceramic Sheet?

Hot Press Boron Nitride (PBN) Ceramic Sheet is a high-performance material made by compressing boron nitride powder under high heat. It has strong thermal stability, electrical insulation, and chemical resistance. It works well in extreme temperatures and harsh environments.

What are the main uses of PBN plates?

PBN plates are used in high-temperature furnaces, semiconductor manufacturing, and laser equipment. They handle molten metals, act as crucibles, or serve as substrates for electronic components. They are common in aerospace, electronics, and research labs due to their reliability under stress.

Why choose PBN over other ceramics?

PBN offers better thermal conductivity than alumina or quartz. It resists most acids and alkalis. It does not react with molten metals or semiconductors. Its low thermal expansion reduces cracking risks during temperature changes. These traits make it last longer in tough conditions.

How to handle and store PBN products?

PBN is brittle. Avoid dropping or applying sudden force. Clean surfaces with alcohol or mild solvents. Do not use abrasive materials. Store in dry areas away from moisture. Keep it separate from materials that might scratch or damage it.

Can PBN sheets be customized?

Yes. Sizes, thicknesses, and surface finishes can be adjusted. Some suppliers offer coatings or machining for specific shapes. Check with manufacturers for technical limits. Custom orders may take longer due to production requirements.

(Hot Press Boron Nitride Ceramic Sheet Pyrolytic Boron Nitride PBN Plate / Substrate / Wafer)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity BN Insulating Ceramic Plate Boron Nitride Sheet

Chemically Stable Boron Nitride Ceramic BN Film

Customized Hot Pressed Hexagonal BN Boron Nitride Ceramic Structural Parts

Hexagonal Boron Nitride Tube Boron Nitride Ceramic Parts

Hexagonal BN Boron Nitride Ring Insulating Ceramic Part