Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction of Boron Carbide Ceramics

Boron carbide ceramics is an inorganic, non-metallic material with carbon and boron as its main components, and its chemical formula is B4C. Since its discovery in the early 20th century, this material has attracted a great deal of attention because of its unique physical and chemical properties. Boron carbide ceramics have an extremely high hardness, second only to diamond and cubic boron nitride, which makes it important in the field of wear-resistant materials. It also exhibits excellent corrosion resistance, high-temperature stability and low-density properties, attributes that make it ideal for the manufacture of bullet-proof vests, nozzles, bearings and other mechanical components that require high wear resistance. Boron carbide ceramics can also be prepared in a variety of shapes and sizes through different processes to meet the needs of different industries.

Characteristics of Boron Carbide Ceramics

Boron carbide ceramics are known for their excellent performance characteristics, starting with their ultra-high hardness and strength, which makes them resistant to severe abrasion and scratching, making them ideal for use in cutting tools and abrasives. Secondly, the material possesses excellent chemical stability and is less likely to react with chemicals such as acids and alkalis, even in extreme environments, making it widely used in certain key components in the chemical industry. In addition, the superior thermal stability of boron carbide ceramics and their ability to maintain structural and property stability at extremely high temperatures makes them one of the key materials in the aerospace and nuclear industries. Finally, it is worth mentioning its lightweight properties, which, due to its low density, make boron carbide ceramics an ideal option for application scenarios that require light weight but high strength. Together, these characteristics give boron carbide ceramics a wide range of applications.

(Customized Hexagonal Boron Carbide Silicon Carbide Ceramic Plate Tiles SIC Ceramic for Industrial Use Welding Cutting Services)

Specification of Customized Hexagonal Boron Carbide Silicon Carbide Ceramic Plate Tiles SIC Ceramic for Industrial Use Welding Cutting Services

Custom-made Hexagonal Boron Carbide Silicon Carbide Porcelain Plate Tiles are designed for industrial welding and reducing applications. These ceramic plates combine hexagonal boron carbide (HBC) and silicon carbide (SiC) for remarkable performance in extreme problems. The product supplies high thermal stability, resisting temperature levels up to 1600 ° C. It keeps architectural integrity under rapid heating and cooling cycles. This makes it perfect for settings with intense heat changes.

The ceramic plates give extraordinary mechanical strength. They hold up against hefty abrasion, influence, and chemical rust. This durability expands the service life of devices in metal processing, aerospace, and automobile industries. The reduced thermal development coefficient minimizes warping during operations. This ensures constant accuracy in welding and reducing tasks.

Customization options consist of varied sizes, densities, and forms. Plates can be tailored to fit certain equipment or tooling requirements. Surface coatings are adjustable for optimal friction control. Perforations or grooves are included for boosted heat dissipation or placing simplicity.

These porcelains exceed conventional steels in high-wear scenarios. They lower downtime by decreasing substitute regularity. Maintenance prices lower as a result of their wear-resistant residential properties. The product’s light-weight nature reduces handling without compromising stamina.

Applications vary from welding nozzles to safety linings in heating systems. They function as heat shields in reducing tools and components for semiconductor manufacturing. The non-reactive surface avoids contamination in delicate procedures.

Quality assurance ensures each plate fulfills rigorous industry standards. Advanced sintering strategies ensure uniform density and marginal problems. Checking consists of thermal shock resistance, hardness checks, and load-bearing evaluations. Conformity with ISO certifications guarantees reliability.

The product suits industries requiring products that withstand extreme mechanical and thermal anxiety. It provides regular efficiency in rough operational environments. Custom remedies are offered for specialized industrial demands.

Resources are sourced from relied on distributors. Manufacturing makes use of accuracy molding and machining for accuracy. Preparations vary based on style intricacy. Mass orders obtain top priority organizing. Technical support helps with integration into existing systems.

These ceramic plates are a cost-efficient upgrade for sturdy applications. They enhance procedure effectiveness while minimizing lasting functional costs. Efficiency information is supplied to confirm viability for certain usage cases.

(Customized Hexagonal Boron Carbide Silicon Carbide Ceramic Plate Tiles SIC Ceramic for Industrial Use Welding Cutting Services)

Applications of Customized Hexagonal Boron Carbide Silicon Carbide Ceramic Plate Tiles SIC Ceramic for Industrial Use Welding Cutting Services

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customized Hexagonal Boron Carbide Silicon Carbide Ceramic Plate Tiles SIC Ceramic for Industrial Use Welding Cutting Services

What materials are used in these ceramic plates?

The plates combine hexagonal boron carbide (HBC) and silicon carbide (SiC). These materials are chosen for their high heat resistance and durability. They handle extreme temperatures and wear better than many metals. The mix ensures strength and thermal stability in tough industrial settings.

Why pick these plates for welding and cutting?

They last longer under high heat and physical stress. Regular metals warp or degrade faster. The ceramic plates keep their shape and performance. This reduces downtime and replacement costs. They also protect equipment from sparks and debris during welding or cutting.

Can the plates be customized for specific needs?

Yes. Sizes, shapes, and thicknesses are adjustable. Holes, grooves, or coatings can be added. Customization ensures the plates fit your machinery and tasks. Tell us your requirements. We adapt the design to match your workflow.

What industries use these ceramic plates?

Metal fabrication, aerospace, automotive, and heavy machinery sectors rely on them. They suit tasks like plasma cutting, laser welding, or grinding. Any process needing heat protection or wear resistance benefits. Factories using high-precision tools often choose these plates.

How do I maintain the plates?

Clean them regularly to remove debris. Check for cracks or chips. Minor damage might not affect performance. Replace plates if wear impacts function. Proper storage avoids unnecessary stress. Their lifespan depends on usage intensity. Most users report years of service under normal conditions.

(Customized Hexagonal Boron Carbide Silicon Carbide Ceramic Plate Tiles SIC Ceramic for Industrial Use Welding Cutting Services)

REQUEST A QUOTE

RELATED PRODUCTS

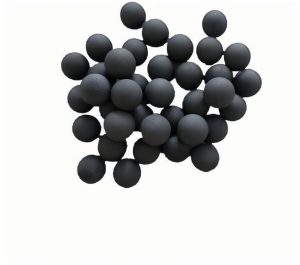

Black Boron Carbide Micro-powder for Manufacturing Ceramic Products

High Purity B4C Boron Carbide Ceramic Grinding Balls

Best Boron Carbide Ceramic in Hexagonal Tiles

High Hardness B4C Boron Carbide Ceramic Tube

Best Boron Carbide Ceramic Nozzle for Sand Blasting