Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction of Boron Carbide Ceramics

Boron carbide ceramics is an inorganic, non-metallic material with carbon and boron as its main components, and its chemical formula is B4C. Since its discovery in the early 20th century, this material has attracted a great deal of attention because of its unique physical and chemical properties. Boron carbide ceramics have an extremely high hardness, second only to diamond and cubic boron nitride, which makes it important in the field of wear-resistant materials. It also exhibits excellent corrosion resistance, high-temperature stability and low-density properties, attributes that make it ideal for the manufacture of bullet-proof vests, nozzles, bearings and other mechanical components that require high wear resistance. Boron carbide ceramics can also be prepared in a variety of shapes and sizes through different processes to meet the needs of different industries.

Characteristics of Boron Carbide Ceramics

Boron carbide ceramics are known for their excellent performance characteristics, starting with their ultra-high hardness and strength, which makes them resistant to severe abrasion and scratching, making them ideal for use in cutting tools and abrasives. Secondly, the material possesses excellent chemical stability and is less likely to react with chemicals such as acids and alkalis, even in extreme environments, making it widely used in certain key components in the chemical industry. In addition, the superior thermal stability of boron carbide ceramics and their ability to maintain structural and property stability at extremely high temperatures makes them one of the key materials in the aerospace and nuclear industries. Finally, it is worth mentioning its lightweight properties, which, due to its low density, make boron carbide ceramics an ideal option for application scenarios that require light weight but high strength. Together, these characteristics give boron carbide ceramics a wide range of applications.

(CAS12069-32-8 Wear Resistant Tool Boron Carbide Powder for Ceramic Reinforcement)

Specification of CAS12069-32-8 Wear Resistant Tool Boron Carbide Powder for Ceramic Reinforcement

CAS12069-32-8 Use Immune Tool Boron Carbide Powder is a high-performance product created for ceramic support. This powder offers extraordinary hardness and durability. It is optimal for applications calling for resistance to wear, deterioration, and extreme temperatures. The item is engineered to improve the toughness and life expectancy of ceramic elements in industrial settings.

Trick specifications consist of a chemical structure of B ₄ C (boron carbide) with a pureness level exceeding 98%. The typical fragment dimension ranges from 0.5 to 5 microns. This great fragment distribution ensures uniform blending with ceramic matrices. The powder has a density of 2.52 g/cm four and a melting point of 2350 ° C. These properties make it secure under high-stress problems.

The product’s Vickers firmness gets to 30-35 GPa. This exceeds most conventional ceramics and metals. It stands up to abrasion effectively. This reduces surface area deterioration in devices and machinery. The powder’s thermal conductivity is reduced. It minimizes warm transfer in high-temperature atmospheres. This protects against thermal shock in enhanced porcelains.

CAS12069-32-8 Boron Carbide Powder is chemically inert. It does not respond with acids or alkalis at area temperature. This makes sure long-lasting security in harsh settings. The product appropriates for usage in ballistic shield, nozzles, and reducing tools. It improves crack strength in ceramic composites.

Production involves advanced synthesis methods. These include carbothermal decrease for regular high quality. The powder goes through stringent quality control. This ensures minimal impurities and ideal performance.

Applications extend aerospace, defense, and manufacturing markets. It strengthens ceramic parts in grinding media, wear plates, and seals. The powder prolongs part lifespan. It reduces upkeep expenses in heavy machinery.

CAS12069-32-8 is packaged in moisture-resistant containers. Storage recommendations consist of cool, completely dry problems. Handling requires basic precaution. This includes handwear covers and masks to stay clear of breathing.

(CAS12069-32-8 Wear Resistant Tool Boron Carbide Powder for Ceramic Reinforcement)

Applications of CAS12069-32-8 Wear Resistant Tool Boron Carbide Powder for Ceramic Reinforcement

CAS 12069-32-8 boron carbide powder is a high-performance material used to strengthen ceramic products. It boosts longevity and use resistance in severe conditions. This makes it perfect for sectors needing tough, lasting parts.

Boron carbide powder has a high firmness level. It is one of the hardest products readily available. This property aids porcelains resist scratches, abrasion, and effect damages. The powder additionally handles heats well. It stays stable in settings up to 2000 ° C. This protects against cracking or weakening under warmth stress.

Chemical resistance is another vital function. Boron carbide does not react with a lot of acids or antacid. This makes it suitable for use in destructive setups. Its reduced thickness adds value. It maintains ceramic components light-weight while maintaining stamina.

In armor systems, boron carbide powder is crucial. It enhances ceramic plates in bulletproof vests and lorry armor. The material’s firmness stops projectiles successfully. This boosts security for military and protection applications.

Industrial devices take advantage of this powder. Cutting devices, grinding discs, and wear plates last much longer when enhanced with boron carbide. This reduces substitute prices and downtime. The powder is added to nozzles and seals in machinery. It aids these components make it through rough materials like sand or coal.

The nuclear market utilizes boron carbide powder for shielding. It soaks up neutrons effectively. This improves security in reactors and waste storage space. The powder’s stability under radiation makes certain reliable long-term performance.

Makers blend boron carbide right into ceramic compounds. This produces products tailored for certain demands. The process entails blending the powder with porcelains prior to sintering. The outcome is a product with boosted sturdiness and put on resistance.

CAS 12069-32-8 boron carbide powder meets rigorous high quality standards. It is offered in controlled particle sizes for consistent results. Industries rely on it to boost item life expectancy and performance. Its adaptability makes it a vital product in innovative engineering services.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of CAS12069-32-8 Wear Resistant Tool Boron Carbide Powder for Ceramic Reinforcement

What is boron carbide powder CAS12069-32-8 used for? This powder is mainly used to reinforce ceramics. It improves hardness and wear resistance in materials like body armor, cutting tools, and industrial nozzles. People choose it because it lasts longer under harsh conditions.

How does boron carbide enhance ceramic materials? The powder bonds tightly with ceramic matrices. This creates a stronger structure. The result is ceramics that resist scratches, cracks, and erosion better. It works well in high-stress environments like mining or machinery parts.

Is boron carbide powder safe to handle? Wear gloves and masks when handling it. The powder is not toxic but can irritate skin or lungs. Store it in a dry, cool place. Keep it away from moisture to prevent clumping or reactions.

What particle sizes are available? Standard sizes range from 1 micron to 50 microns. Smaller particles fit better for precise coatings. Larger ones suit bulk reinforcement. Custom sizes can be made based on specific needs.

Can boron carbide withstand high temperatures? Yes. It stays stable up to 2000°C in inert atmospheres. This makes it ideal for high-heat uses like furnace linings or aerospace components. It keeps its properties without breaking down.

(CAS12069-32-8 Wear Resistant Tool Boron Carbide Powder for Ceramic Reinforcement)

REQUEST A QUOTE

RELATED PRODUCTS

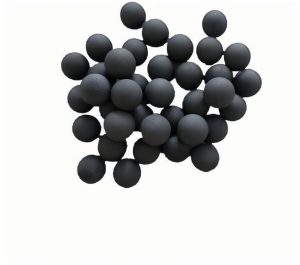

Hot Press Sintered Boron Carbide B4C Ball Boron Carbide Ceramic Protective Ball

Hot Press Sintered Boron Carbide B4C Plate

Silicon Carbide Boron Carbide Alumina Ceramic Armor Plate

Hot Pressing Sintered B4C Boron Carbide Pressureless Sintering Ceramic Parts

High Hardness B4C Boron Carbide Ceramic Tube