Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction of Boron Carbide Ceramics

Boron carbide ceramics is an inorganic, non-metallic material with carbon and boron as its main components, and its chemical formula is B4C. Since its discovery in the early 20th century, this material has attracted a great deal of attention because of its unique physical and chemical properties. Boron carbide ceramics have an extremely high hardness, second only to diamond and cubic boron nitride, which makes it important in the field of wear-resistant materials. It also exhibits excellent corrosion resistance, high-temperature stability and low-density properties, attributes that make it ideal for the manufacture of bullet-proof vests, nozzles, bearings and other mechanical components that require high wear resistance. Boron carbide ceramics can also be prepared in a variety of shapes and sizes through different processes to meet the needs of different industries.

Characteristics of Boron Carbide Ceramics

Boron carbide ceramics are known for their excellent performance characteristics, starting with their ultra-high hardness and strength, which makes them resistant to severe abrasion and scratching, making them ideal for use in cutting tools and abrasives. Secondly, the material possesses excellent chemical stability and is less likely to react with chemicals such as acids and alkalis, even in extreme environments, making it widely used in certain key components in the chemical industry. In addition, the superior thermal stability of boron carbide ceramics and their ability to maintain structural and property stability at extremely high temperatures makes them one of the key materials in the aerospace and nuclear industries. Finally, it is worth mentioning its lightweight properties, which, due to its low density, make boron carbide ceramics an ideal option for application scenarios that require light weight but high strength. Together, these characteristics give boron carbide ceramics a wide range of applications.

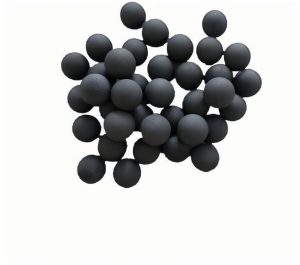

(Hot Press Sintered Boron Carbide B4C Ball Boron Carbide Ceramic Protective Ball)

Specification of Hot Press Sintered Boron Carbide B4C Ball Boron Carbide Ceramic Protective Ball

Hot Press Sintered Boron Carbide (B4C) Round is a high-performance ceramic product developed for severe environments. The material incorporates extraordinary hardness, light-weight homes, and resistance to use, deterioration, and high temperatures. Boron carbide ranks third in solidity after diamond and cubic boron nitride, making it ideal for applications requiring resilience. The warm press sintering procedure makes sure high density and architectural integrity, decreasing porosity and enhancing mechanical stamina.

The product includes a purity degree of over 98%, with a typical solidity of 28-35 GPa. Its density varies between 2.45-2.55 g/cm FOUR, balancing stamina and weight effectiveness. The compressive stamina goes beyond 2900 MPa, ideal for heavy-load conditions. Thermal security permits procedure as much as 1000 ° C in inert ambiences, preserving efficiency under warm. Thermal conductivity is approximately 30-42 W/m · K, helping warmth dissipation in high-temperature settings.

Readily available in sizes from 5 mm to 50 mm, the spheres are adjustable for details requirements. Surface area coatings can be brightened to Ra 0.2 μm or kept as-sintered for harsh applications. Limited dimensional tolerances ( ± 0.05 mm) ensure precision in setting up and performance. The material’s chemical inertness stands up to acids, antacid, and molten metals, expanding service life in harsh settings.

Primary applications include armor systems, ballistic protection, and wear-resistant components in commercial equipment. The spheres are utilized in accuracy bearings, shutoffs, and pumps for rough media handling. In the aerospace field, they act as light-weight armor parts. The energy market employs them in atomic power plant control poles due to boron’s neutron absorption.

Handling guidelines advise staying clear of impact loading past the material’s restrictions. Machining needs ruby devices as a result of severe solidity. Appropriate handling prevents surface area damages throughout installment. Storage space in dry problems prevents moisture-related degradation.

The product meets MIL-DTL-32598 and ASTM C750 criteria, making sure reliability for protection and commercial usages. Customized specs for size, surface high quality, and screening methods are offered. Technical assistance aids with product selection and application optimization.

(Hot Press Sintered Boron Carbide B4C Ball Boron Carbide Ceramic Protective Ball)

Applications of Hot Press Sintered Boron Carbide B4C Ball Boron Carbide Ceramic Protective Ball

Warm press sintered boron carbide (B4C) ceramic protective rounds are sophisticated materials understood for severe solidity and resilience. These rounds are made by condensing boron carbide powder under high warm and stress. This process creates a dense structure immune to wear, corrosion, and heats. Their one-of-a-kind residential or commercial properties make them important throughout multiple markets.

In body armor and military gear, boron carbide balls offer lightweight security. They quit bullets and shrapnel far better than steel. This makes armor lighter for soldiers and security employees. Their strength-to-weight proportion is unmatched by standard products.

Industrial reducing tools utilize boron carbide rounds to prolong device life. They take care of unpleasant materials like concrete or solidified steels. Devices last longer, decreasing downtime and expenses. The rounds keep sharp sides also under hefty use.

Unpleasant blowing up applications count on boron carbide spheres for reliable surface preparation. They clean or form metals and composites without breaking down. This enhances blowing up speed and lowers waste. Their durability guarantees constant results in time.

Atomic power plants utilize boron carbide spheres as control poles or securing components. They take in neutrons properly, improving activator safety. Their stability in radiation and warmth stops destruction. This makes certain dependable efficiency in crucial settings.

Aerospace systems take advantage of boron carbide balls in parts subjected to severe problems. They stand up to high-speed influences and thermal stress and anxiety. Their lightweight nature helps reduce fuel intake. This is crucial for spacecraft and high-performance airplane.

In precision machinery, boron carbide rounds act as bearings or overviews. They lessen rubbing in high-speed operations. Their resistance to chemical corrosion fits rough commercial setups. This boosts equipment accuracy and long life.

Boron carbide rounds are likewise made use of in wear-resistant components for pumps and shutoffs. They avoid erosion in slurry transport or chemical processing. This extends tools life and lowers maintenance requirements. Their inertness to acids and alkalis adds flexibility.

The mix of solidity, lightweight, and thermal stability makes hot press sintered boron carbide spheres important for requiring applications. Industries choose them for efficiency under anxiety without including bulk.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Hot Press Sintered Boron Carbide B4C Ball Boron Carbide Ceramic Protective Ball

What is Hot Press Sintered Boron Carbide B4C Ball made of?

Hot Press Sintered Boron Carbide B4C Ball is made of boron carbide ceramic. Boron carbide has boron and carbon atoms arranged in a strong crystal structure. The hot press sintering method compresses and heats boron carbide powder at high temperatures. This creates dense, hard ceramic balls with minimal pores.

Where is this boron carbide ceramic ball used?

This ceramic ball is used in industrial applications needing extreme wear resistance. Common uses include bulletproof armor, abrasive blasting nozzles, and precision bearings. It protects machinery parts exposed to harsh conditions. It works in high-stress environments like mining, aerospace, and military equipment.

Why choose boron carbide over other ceramics?

Boron carbide is harder than most ceramics. It ranks third in hardness after diamond and cubic boron nitride. It resists wear better than materials like alumina or silicon carbide. It stays stable under high temperatures and radiation. This makes it last longer in tough conditions.

Can boron carbide balls handle high temperatures?

Boron carbide balls handle temperatures up to 600°C in air. They stay strong and resist oxidation. In inert atmospheres or vacuum environments, they withstand even higher temperatures. They do not soften or deform under heat like metals.

How to maintain boron carbide ceramic protective balls?

Boron carbide balls need minimal maintenance. Clean them regularly with non-abrasive methods to remove debris. Avoid impacts from hard objects to prevent chipping. Check for surface cracks during inspections. Replace balls showing visible damage to ensure performance.

(Hot Press Sintered Boron Carbide B4C Ball Boron Carbide Ceramic Protective Ball)

REQUEST A QUOTE

RELATED PRODUCTS

High Hardness B4C Boron Carbide Ceramic Tube

High Purity B4C Boron Carbide Ceramic Grinding Balls

Silicon Carbide Boron Carbide Alumina Ceramic Armor Plate

Black Boron Carbide Micro-powder for Manufacturing Ceramic Products

CAS12069-32-8 Wear Resistant Tool Boron Carbide Powder for Ceramic Reinforcement