Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction of Boron Carbide Ceramics

Boron carbide ceramics is an inorganic, non-metallic material with carbon and boron as its main components, and its chemical formula is B4C. Since its discovery in the early 20th century, this material has attracted a great deal of attention because of its unique physical and chemical properties. Boron carbide ceramics have an extremely high hardness, second only to diamond and cubic boron nitride, which makes it important in the field of wear-resistant materials. It also exhibits excellent corrosion resistance, high-temperature stability and low-density properties, attributes that make it ideal for the manufacture of bullet-proof vests, nozzles, bearings and other mechanical components that require high wear resistance. Boron carbide ceramics can also be prepared in a variety of shapes and sizes through different processes to meet the needs of different industries.

Characteristics of Boron Carbide Ceramics

Boron carbide ceramics are known for their excellent performance characteristics, starting with their ultra-high hardness and strength, which makes them resistant to severe abrasion and scratching, making them ideal for use in cutting tools and abrasives. Secondly, the material possesses excellent chemical stability and is less likely to react with chemicals such as acids and alkalis, even in extreme environments, making it widely used in certain key components in the chemical industry. In addition, the superior thermal stability of boron carbide ceramics and their ability to maintain structural and property stability at extremely high temperatures makes them one of the key materials in the aerospace and nuclear industries. Finally, it is worth mentioning its lightweight properties, which, due to its low density, make boron carbide ceramics an ideal option for application scenarios that require light weight but high strength. Together, these characteristics give boron carbide ceramics a wide range of applications.

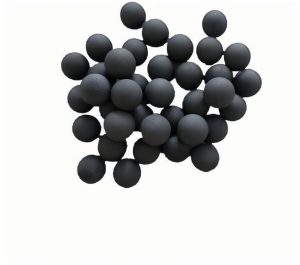

(Black Boron Carbide Micro-powder for Manufacturing Ceramic Products)

Specification of Black Boron Carbide Micro-powder for Manufacturing Ceramic Products

Black boron carbide micro-powder is a high-performance product made use of in producing innovative ceramic products. It has phenomenal hardness, thermal security, and chemical resistance. These homes make it suitable for demanding industrial applications. The powder is generated with sophisticated synthesis techniques to ensure regular top quality.

The chemical structure of the powder is mainly boron carbide (B4C), with a common web content of 95% to 98%. Pollutants like oxygen, nitrogen, and metallic elements are firmly controlled. Bit dimension circulation varies from 0.5 to 5 micrometers. This fine granularity allows uniform combining with ceramic matrices. The powder’s high purity decreases flaws in final products.

Physical homes consist of a density of 2.52 g/cm ³ and a melting factor over 2400 ° C. It preserves architectural stability under extreme temperatures. The material’s Vickers solidity surpasses 30 GPa, making it harder than many porcelains. This firmness enhances wear resistance in elements like cutting tools and shield plates.

The powder is compatible with sintering processes typical in ceramic production. It bonds well with alumina, silicon carbide, and various other ceramic precursors. Processing temperatures between 1800 ° C and 2200 ° C accomplish ideal densification. The outcome is porcelains with boosted mechanical stamina and thermal shock resistance.

Applications consist of ballistic shield, rough nozzles, and wear-resistant linings. It is additionally made use of in atomic power plants as a neutron absorber. Manufacturers value its ability to reduce component weight while maintaining efficiency. The powder is readily available in customized fragment dimensions for particular production demands.

Security standards advise managing the powder in well-ventilated locations. Straight skin call need to be prevented. Storage conditions need a dry environment to avoid moisture absorption. Proper individual safety equipment, consisting of masks and handwear covers, is important during use.

This product goes through extensive top quality screening. Batch-specific certifications of analysis are provided. Technical support is offered for combination right into existing production workflows. The powder meets international criteria for commercial ceramics.

(Black Boron Carbide Micro-powder for Manufacturing Ceramic Products)

Applications of Black Boron Carbide Micro-powder for Manufacturing Ceramic Products

Black boron carbide micro-powder is a crucial material for making advanced ceramic products. It has high hardness, solid thermal security, and exceptional wear resistance. These residential or commercial properties make it suitable for commercial uses where toughness issues.

Ceramic shield items utilize black boron carbide micro-powder. It helps produce lightweight, high-strength plates for armors and lorry security. The product soaks up impact power well. This lowers damages from bullets or explosions.

Industrial ceramic components gain from this powder. Components like seals, bearings, and nozzles last longer. The powder stands up to damage in severe settings. Equipments run smoother with less substitutes.

High-temperature tools make use of porcelains made with black boron carbide. Furnace cellular linings and heat shields manage severe warm without fracturing. The powder’s thermal security maintains frameworks intact at over 2,000 ° C.

Electronics making relies upon porcelains with this material. Semiconductor handling devices require precision and chemical resistance. Black boron carbide porcelains avoid contamination. They stay stable throughout etching or finish processes.

Aerospace applications demand dependable materials. Ceramic turbine blades and engine parts made with this powder stand up to stress and anxiety and warmth. Fuel efficiency improves as components sustain longer under stress.

Chemical plants use corrosion-resistant ceramics. Mixing storage tanks and pipes made with black boron carbide micro-powder stand up to acids and antacids. Devices lasts much longer in aggressive chemical atmospheres.

The powder’s great fragments enable exact shaping during manufacturing. Ceramic products maintain limited tolerances for complicated layouts. Producers save prices with less product waste.

Black boron carbide micro-powder works in additive production. 3D-printed ceramic components acquire stamina and information. Custom shapes for clinical or engineering uses ended up being simpler to create.

Environmental applications include filters and stimulants. Ceramics with this powder trap pollutants or quicken chain reactions. Air and water therapy systems operate a lot more effectively.

The product’s versatility supports technology across sectors. Its combination of hardness, heat resistance, and chemical stability meets modern manufacturing needs.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Black Boron Carbide Micro-powder for Manufacturing Ceramic Products

Black boron carbide micro-powder is a material used in manufacturing high-performance ceramics. Below are answers to common questions.

What is black boron carbide micro-powder?

This powder is a fine, dark-colored substance made of boron and carbon. It has a high melting point and extreme hardness. Manufacturers use it to strengthen ceramics.

Why choose boron carbide for ceramic products?

Boron carbide improves ceramic durability and heat resistance. It works well in extreme conditions. Ceramics made with it last longer under stress or high temperatures.

Does particle size matter in the powder?

Particle size affects how the powder mixes with ceramics. Smaller particles spread evenly and bond better. This creates stronger final products with fewer weak spots.

Is the powder safe to handle?

Direct contact with skin or eyes should be avoided. The powder is abrasive and can cause irritation. Workers must wear gloves and masks during processing.

How does boron carbide compare to other materials?

Boron carbide is harder than silicon carbide or aluminum oxide. It offers better wear resistance. It costs more but provides superior performance in demanding applications.

Can it be used with all types of ceramics?

It works best with ceramics needing high hardness and thermal stability. Compatibility depends on the base material and production method. Testing small batches first is recommended.

(Black Boron Carbide Micro-powder for Manufacturing Ceramic Products)

REQUEST A QUOTE

RELATED PRODUCTS

Best Boron Carbide Ceramic in Hexagonal Tiles

High Hardness B4C Boron Carbide Ceramic Tube

Hot Press Sintered Boron Carbide B4C Plate

Silicon Carbide Boron Carbide Alumina Ceramic Armor Plate

High Purity B4C Boron Carbide Ceramic Grinding Balls