Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

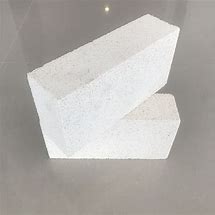

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Fine Ceramic 99% Alumina Ceramic Tube)

Specifications of Fine Ceramic 99% Alumina Ceramic Tube

The Fine Ceramic 99% Alumina Ceramic Tube is created for high-performance applications. It contains 99% light weight aluminum oxide, guaranteeing outstanding chemical security. The material withstands rust from acids and antacids. It runs accurately in severe environments. The tube has a dense structure with reduced porosity. This avoids gas or fluid infiltration. Its surface area is smooth, lowering rubbing during use. The product keeps toughness under severe temperature levels. It deals with temperature levels approximately 1650 ° C. Thermal shock resistance is solid. Quick temperature level modifications cause very little damages. The ceramic tube functions as an electric insulator. It operates in high-voltage conditions without conductivity dangers. Mechanical longevity is high. Television withstands wear, abrasion, and effect. Its hardness exceeds most metals. This prolongs service life sought after settings. Measurements are personalized. External sizes range from 1mm to 200mm. Wall surface thickness differs based upon application demands. Lengths get used to fit specific demands. Resistances are tightly managed. Accuracy machining makes certain consistent quality. Television fits vacuum systems. It performs well in high-purity processes. No pollutants leach from the material. It meets requirements for semiconductor manufacturing. Applications consist of furnace parts, thermocouple protection, and laser systems. The tube is ideal for aerospace and clinical devices. It operates in kilns, sensors, and logical instruments. Compatibility with hostile chemicals is verified. No deterioration happens in acidic or alkaline solutions. The product is non-reactive with liquified steels. It sustains metallurgical processes. Personalized surface area therapies are offered. Sprucing up or layer boosts efficiency. Testing consists of density checks and thermal cycling. Each set undergoes quality verification. The alumina tube is packaged safely. Damages during shipping is minimized. Technical assistance is provided for product selection. Efficiency information is provided upon demand.

(Fine Ceramic 99% Alumina Ceramic Tube)

Applications of Fine Ceramic 99% Alumina Ceramic Tube

Fine Ceramic 99% Alumina Porcelain Tube is a high-performance material commonly made use of in markets calling for longevity and accuracy. It has 99% light weight aluminum oxide, giving it remarkable warm resistance, electrical insulation, and chemical stability. Its mechanical toughness makes it perfect for demanding environments.

In electronic devices, this ceramic tube works as shielding components for circuits and sensors. It stops electrical leakage also at high temperatures. It is utilized in substratums for digital tools and protective real estates for sensitive sensing units. The material makes sure steady efficiency in power systems and communication equipment.

The metallurgy market utilizes these tubes as protective sheaths for thermocouples in high-temperature heating systems. They withstand molten steel and harsh gases. This guarantees accurate temperature dimensions during metal handling. Televisions additionally deal with thermal shock without breaking.

Chemical handling plants depend on alumina ceramic tubes for handling hostile substances. They line reactors and transfer destructive liquids or gases. Their resistance to acids and antacid reduces wear in pumps and shutoffs. This expands tools life and lowers upkeep expenses.

Semiconductor producing usages these tubes in wafer-processing devices. They keep purity in high-temperature atmospheres. Their non-reactive nature prevents contamination throughout crystal development or etching processes.

Aerospace applications consist of sensing unit protection in engines and exhaust systems. Televisions sustain severe warmth and vibration. They ensure trusted data collection in rough problems.

Medical devices make use of alumina ceramic tubes for their biocompatibility. They are located in laboratory devices and surgical tools. The product stands up to repeated sterilization without breaking down.

Power systems like fuel cells and batteries make use of these tubes for thermal administration. They protect electrical elements while carrying out heat successfully. This enhances safety and effectiveness in power storage and conversion.

The convenience of Great Ceramic 99% Alumina Porcelain Tube makes it vital throughout innovative industries. Its properties resolve difficulties in high-stress, high-temperature, and corrosive setups.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Fine Ceramic 99% Alumina Ceramic Tube

What is the maximum temperature the Fine Ceramic 99% Alumina Ceramic Tube can handle? The tube withstands temperatures up to 1650°C. It works well in high-heat settings like industrial furnaces. The material stays stable under extreme heat. It resists thermal shock better than many metals. This makes it reliable for repeated heating cycles.

Does the alumina ceramic tube resist chemicals? Yes. It resists most acids, alkalis, and organic solvents. This makes it suitable for labs or chemical processing plants. The material does not corrode easily. It keeps its structure even in harsh environments. This ensures long-term performance without degradation.

Where is this ceramic tube commonly used? It is used in industries like semiconductors, aerospace, and medical devices. Applications include thermocouple protection, insulating components, and precision machinery parts. Its high wear resistance suits abrasive environments. It also works in electrical insulation systems.

How does 99% alumina ceramic differ from other ceramics? The 99% alumina content gives higher purity. This improves hardness, heat resistance, and electrical insulation. It outperforms lower-purity alumina ceramics. Compared to zirconia ceramics, it handles higher temperatures but is less flexible. The trade-off is worth it for extreme conditions.

Can the tube be customized for specific needs? Yes. Manufacturers adjust dimensions, shapes, and surface finishes. Holes, grooves, or threads can be added. Customization depends on application requirements. Production times vary with complexity. Most suppliers work closely with clients to meet exact specs.

(Fine Ceramic 99% Alumina Ceramic Tube)

REQUEST A QUOTE

RELATED PRODUCTS

Al2O3 Ceramic Large size aluminium oxide ceramic plates and discs Alumina ceramic round plate

Porous Semiconductor Ceramics/insulating Electronic Ceramics/995 Alumina Ceramics

Heat-resistant and Impact-resistant Alumina Ceramics for Sintering Kilns

Long Service Life Materials Made of Ceramics 95 99 Al2o3 Insulator Alumina Ceramic Ring

Al2O3 Ceramic 6mm,20mm Inert Alumina Ceramic Ball as Catalyst Support Media Ceramic Ball