Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

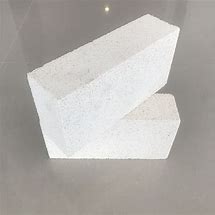

(Ceramic Base Industrial Ceramics 95% Alumina Ceramic Part)

Specifications of Ceramic Base Industrial Ceramics 95% Alumina Ceramic Part

The ceramic base industrial ceramics 95% alumina ceramic component is made primarily from light weight aluminum oxide. This material consists of 95% alumina content. It supplies high mechanical stamina. The component withstands wear properly. It takes care of extreme temperatures well. The maximum operating temperature reaches 1600 ° C. Thermal shock resistance is strong. Sudden temperature level adjustments cause minimal damages. Electrical insulation homes are exceptional. The part works in high-voltage environments securely. Chemical security is reputable. It withstands rust from acids and antacids. Surface smoothness is high. Precision machining makes certain tight tolerances. Dimensional precision fulfills commercial standards. Custom shapes and sizes are available. Applications consist of electronic devices, equipment, and chemical handling. In electronics, it functions as insulators or substrates. In equipment, it serves as wear-resistant elements. In chemical equipment, it operates as corrosion-resistant parts. The density ranges between 3.6 and 3.9 g/cm THREE. Hardness surpasses 80 HRA. Flexural stamina procedures over 300 MPa. Compressive stamina surpasses 2000 MPa. The dielectric toughness is above 15 kV/mm. Thermal conductivity is modest. It balances warmth dissipation and insulation. The material is non-porous. It prevents contamination in tidy atmospheres. Machining alternatives consist of grinding, splashing, and polishing. Surface area finishes can be customized. Roughness degrees meet particular needs. The component works with metalizing and brazing procedures. Assimilation with steel settings up is seamless. Long life span decreases replacement expenses. Performance continues to be secure under constant stress and anxiety. It fits high-frequency applications. Signal loss is minimal. The part meets RoHS and REACH criteria. It is environmentally secure. Manufacturing uses high-purity basic materials. Quality control ensures consistency. Evaluating includes dimensional checks and building verification. Examples are available for analysis. Mass orders receive personalized support. Technical specs can be changed. Shipment timelines are versatile. The item is stuffed safely. Damage during transportation is prevented.

(Ceramic Base Industrial Ceramics 95% Alumina Ceramic Part)

Applications of Ceramic Base Industrial Ceramics 95% Alumina Ceramic Part

Industrial porcelains made from 95% alumina are extensively used across numerous markets due to their high performance and dependability. These ceramic parts handle extreme conditions better than many steels or plastics. In electronics, they function as substratums for circuits, insulators, and elements in high-voltage systems. Their capability to carry out heat while obstructing electricity makes them suitable for tools requiring temperature control and electric security.

In machinery and production, alumina ceramics protect devices from damage. They line pumps, shutoffs, and bearings in durable settings. Their solidity stands up to abrasion, prolonging the life-span of tools subjected to friction. Manufacturing facilities utilize them as reducing devices or guides in precision machining, where security under stress and anxiety matters.

The medical field relies upon these ceramics for implants and surgical devices. Their biocompatibility avoids reactions in the body. They prevail in hip replacements, oral prosthetics, and bone screws. Sterilization processes do not damage them, making reusable tools safer and extra durable.

Chemical plants use alumina ceramic parts to deal with destructive substances. They stand up to acids, alkalis, and high temperatures without breaking down. Reactor cellular linings, laboratory devices, and piping systems gain from their resistance to chemical attack. This minimizes downtime and maintenance expenses in aggressive atmospheres.

Alumina ceramics additionally support power applications. They shield parts in power generation systems, such as wind turbines or photovoltaic panels. Their thermal security makes sure effectiveness in high-heat settings. Automotive systems use them in sensors and engine components to improve efficiency under extreme operating problems.

Custom-made sizes and shapes are achievable through innovative manufacturing techniques. Pressing, extrusion, and machining permit accurate designs customized to details demands. This flexibility guarantees compatibility with varied industrial needs.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Ceramic Base Industrial Ceramics 95% Alumina Ceramic Part

What is 95% alumina ceramic? This material is made from aluminum oxide. It contains 95% aluminum oxide. The rest includes other oxides. It is durable. It resists wear. It handles high temperatures. It works in harsh environments. It is common in industrial parts.

How heat-resistant is 95% alumina ceramic? It withstands temperatures up to 1600°C. It keeps strength in high heat. Metals or plastics fail at lower temperatures. It does not melt easily. It does not deform under stress. It suits furnaces, engines, and high-heat machinery.

Where is 95% alumina ceramic used? It is used in electronics. It insulates circuits. It is used in automotive parts. It cuts metal. It lines pumps in chemical plants. It works in medical tools. It resists corrosion. It handles abrasive materials.

What are the benefits over other materials? It is harder than steel. It resists acids and alkalis. It does not rust. It insulates electricity. Metals conduct electricity. Plastics melt under high heat. It lasts longer in tough conditions.

How is 95% alumina ceramic handled or machined? It is hard. It is brittle. Diamond tools cut or grind it. Standard tools damage it. Avoid sudden impacts. Handle with care. Custom shapes need professional machining. Precise parts require controlled processes.

(Ceramic Base Industrial Ceramics 95% Alumina Ceramic Part)

REQUEST A QUOTE

RELATED PRODUCTS

Al2O3 Ceramic Hot Selling Refractory Alumina Brick Kiln Rotary Kiln Building Making Clay Brick For Oven

High Strength 99 Alumina Textile Ceramic for Factory Use

High Temperature Alumina Ceramic And Temperature Resistant For Alumina Ceramic Tube

Al2O3 Ceramic HIgh Temperature Thermal Alumina Ceramic Crucible For Sale

Industrial Electrical Technical Machinery Custom High Heat Resistant Ceramics Alumina Structural Parts