Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

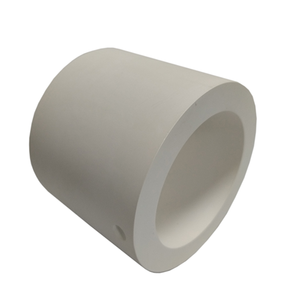

(High Strength 99 Alumina Textile Ceramic for Factory Use)

Specifications of High Strength 99 Alumina Textile Ceramic for Factory Use

High Toughness 99 Alumina Fabric Ceramic matches manufacturing facility setups needing reliable performance. It includes 99% aluminum oxide. This guarantees high mechanical toughness. The product takes care of hefty loads without damage. It withstands extreme temperature levels up to 1650 ° C. Thermal stability avoids cracking under fast home heating or air conditioning. Manufacturing facilities utilize it in high-heat zones without failure.

The ceramic offers extraordinary wear resistance. Abrasive atmospheres cause marginal surface disintegration. This prolongs life span in machinery components like rollers or guides. Thickness reaches 3.9 g/cm TWO. High thickness boosts longevity under anxiety. It works in heavy-duty applications without deteriorating.

Dimensions differ for custom needs. Criterion density ranges from 6 mm to 50 mm. Dimensions adapt to industrial tools requirements. Surface finish is smooth. Reduced rubbing minimizes power loss in relocating components. Precision grinding makes sure limited resistances. Parts fit flawlessly into existing systems.

Chemical inertness makes it ideal for destructive setups. Acids and antacids do not respond with the product. It remains secure in rough chemical procedures. Electrical insulation properties prevent conductivity. This stays clear of short circuits in electronic manufacturing configurations.

Factories use the ceramic in textile machinery, metal processing, and kiln linings. It replaces standard steels vulnerable to put on. Upkeep expenses go down as a result of durable performance. Customized forms are available for specialized tools. The product meets ISO criteria for industrial porcelains.

High Stamina 99 Alumina Textile Porcelain reduces downtime in production lines. Its flexibility fits diverse manufacturing difficulties. The material endures mechanical, thermal, and chemical anxiety. Factories accomplish higher effectiveness with minimal replacements.

(High Strength 99 Alumina Textile Ceramic for Factory Use)

Applications of High Strength 99 Alumina Textile Ceramic for Factory Use

High-strength 99 alumina textile ceramic is a specialized product widely utilized in industrial setups. It contains 99% light weight aluminum oxide, providing it remarkable firmness, warm resistance, and toughness. Manufacturing facilities count on it for requiring settings where typical products fail.

One vital application is high-temperature equipment. Metal handling plants use it as linings for heating systems, kilns, and heat therapy devices. It stands up to temperatures over 1600 ° C without splitting. This avoids warmth damage to equipment parts. It additionally works as guides or rollers in high-heat conveyor systems. These elements manage liquified steels or glass without deteriorating.

Chemical plants take advantage of its corrosion resistance. It lines activators, pipes, and storage tanks exposed to harsh acids or antacid. Unlike metals, it does not corrosion or react with chemicals. This prolongs tools life expectancy. It is additionally utilized in pumps and shutoffs dealing with unpleasant slurries. The material stands up to wear from fragments in liquids, reducing upkeep prices.

In electronic devices making, it serves as insulation for high-voltage tools. Its electrical resistance prevents short circuits in power distribution systems. Manufacturing facilities utilize it in circuit board handling tools. It stays clear of fixed build-up, securing delicate components. Semiconductor production uses it for wafer service providers. It withstands severe warmth during chip fabrication.

Manufacturing facilities with hefty equipment use it for wear-resistant parts. Bearings, seals, and reducing devices made from this ceramic last longer than steel. It decreases downtime for substitutes. Textile mills install it in spinning or weaving devices. Guides and tension poles made from it decrease fiber friction. This guarantees smooth operation in high-speed production.

An additional location is fire safety. It lines commercial chimneys and exhaust systems. The product obstructs flames and extreme warmth, protecting against structural damage. Factories handling combustible products use it as protective barriers.

High-strength 99 alumina fabric ceramic boosts efficiency across sectors. Its sturdiness and adaptability resolve issues in severe operating conditions. Factories accomplish higher performance with less tools failures.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Strength 99 Alumina Textile Ceramic for Factory Use

High Strength 99 Alumina Textile Ceramic is designed for industrial applications. Below are answers to common questions.

What is High Strength 99 Alumina Textile Ceramic?

This material is made from 99% alumina. It combines ceramic durability with textile flexibility. It resists extreme heat, wear, and chemicals. Factories use it in high-stress environments where metals or plastics fail.

How does it handle high temperatures?

The ceramic withstands temperatures up to 1600°C. It stays stable under rapid heating or cooling. This makes it ideal for furnaces, kilns, and metal processing. It does not warp or crack like traditional materials.

Is it durable in harsh conditions?

Yes. The high alumina content provides exceptional hardness. It resists abrasion, corrosion, and chemical exposure. It lasts longer than rubber or steel in acidic or alkaline settings. Maintenance costs drop due to reduced replacement needs.

Where is it used in factories?

Common applications include conveyor belts, seals, and insulation. It lines machinery exposed to heat or friction. Textile factories use it in guides and rollers. Mining and chemical plants rely on it for equipment protection.

Is it safe for industrial use?

The material is non-toxic and chemically inert. It does not release harmful substances under heat or stress. It meets safety standards for factories handling food, pharmaceuticals, or hazardous chemicals. Proper installation ensures minimal risk of breakage.

The product’s versatility and reliability make it a practical choice for demanding industrial tasks.

(High Strength 99 Alumina Textile Ceramic for Factory Use)

REQUEST A QUOTE

RELATED PRODUCTS

Fine Ceramic 99% Alumina Ceramic Tube

Al2O3 Ceramic 6mm,20mm Inert Alumina Ceramic Ball as Catalyst Support Media Ceramic Ball

Ceramic Base Industrial Ceramics 95% Alumina Ceramic Part

Al2O3 Ceramic HIgh Temperature Thermal Alumina Ceramic Crucible For Sale

Long Service Life Materials Made of Ceramics 95 99 Al2o3 Insulator Alumina Ceramic Ring