Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

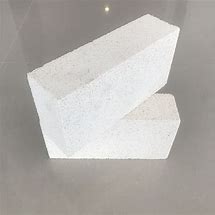

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(High Temperature Alumina Ceramic And Temperature Resistant For Alumina Ceramic Tube)

Specifications of High Temperature Alumina Ceramic And Temperature Resistant For Alumina Ceramic Tube

High-temperature alumina ceramic is a specialized product designed for extreme warm settings. It manages temperature levels up to 1800 ° C without losing architectural integrity. This makes it excellent for commercial applications requiring prolonged direct exposure to intense warmth. The key part is aluminum oxide (Al two O SIX), with purity degrees ranging from 95% to 99.5%. Higher pureness qualities offer better performance in corrosive or high-wear problems. Alumina ceramic tubes made from this product are commonly utilized in heaters, kilns, and thermal handling tools.

The material’s thickness usually drops in between 3.6 and 3.9 g/cm ³. This guarantees durability while keeping a lightweight profile. Alumina ceramic tubes resist thermal shock efficiently. Fast temperature level adjustments from 1000 ° C to room temperature level cause marginal breaking or contortion. The reduced thermal development coefficient contributes to this stability. Mechanical strength is one more vital feature. Flexural strength arrays from 300 to 400 MPa, enabling televisions to hold up against hefty lots and mechanical tension.

Chemical resistance is a vital advantage. Alumina ceramic tubes resist acids, antacid, and molten steels. This makes them appropriate for chemical processing or metal casting. Electric insulation properties continue to be secure also at heats. Dielectric stamina goes beyond 15 kV/mm, protecting against electric breakdown popular environments.

Standard tube measurements differ by application. External sizes range from 5 mm to 200 mm. Wall thicknesses start at 1 mm for accuracy uses. Custom dimensions are offered for specialized demands. Surface area coating choices include brightened, glazed, or as-sintered. A smooth surface reduces friction in high-velocity gas or fluid flow systems.

Temperature-resistant alumina ceramic tubes are examined carefully. Quality checks guarantee dimensional precision and efficiency uniformity. Common sectors utilizing these tubes consist of aerospace, metallurgy, and semiconductor manufacturing. Their dependability in severe conditions makes them a favored option for engineers and service technicians.

(High Temperature Alumina Ceramic And Temperature Resistant For Alumina Ceramic Tube)

Applications of High Temperature Alumina Ceramic And Temperature Resistant For Alumina Ceramic Tube

High-temperature alumina ceramic products are widely utilized in industries needing severe warmth resistance. These ceramics deal with temperatures approximately 1800 ° C without losing architectural stability. Metallurgical processes utilize them for heater linings, crucibles, and safety sleeves. Aerospace applications include thermal obstacles for engine parts. Electronics making relies on alumina porcelains for insulating components in high-power tools. Chemical plants utilize them in reactors and piping systems as a result of their corrosion resistance.

Alumina ceramic tubes excel in high-temperature settings. They keep security under extended warm direct exposure. Their reduced thermal expansion protects against breaking throughout quick temperature level adjustments. These tubes withstand chemical reactions with acids, alkalis, and molten metals. This makes them perfect for rough commercial setups.

The temperature level resistance of alumina ceramic tubes comes from their high pureness aluminum oxide content. This make-up guarantees marginal contortion under tension. The product’s thick framework obstructs gas infiltration. This reduces oxidation damages in vacuum or inert gas atmospheres.

Industrial heater utilize alumina tubes as thermocouple security sheaths. They protect sensing units from straight fire contact. Lab equipment uses these tubes for example containment in high-temperature screening. Semiconductor producing utilizes them for wafer-processing chambers. Thermal processing units count on alumina tubes for even warm circulation.

Mechanical toughness allows alumina ceramic tubes to hold up against physical stress and anxiety. They withstand wear from abrasive products in industrial process. Electric insulation residential or commercial properties make them risk-free for high-voltage applications. Their smooth surface avoids contamination in cleanroom settings.

Personalized measurements and forms adjust alumina tubes to specific needs. They fit securely into complex machinery designs. Compatibility with advanced joining techniques ensures leak-free settings up. This decreases maintenance expenses in high-temperature procedures.

Alumina ceramic tubes outmatch metal alternatives in severe conditions. Metals oxidize or thaw under intense warm. Polymers weaken promptly. Alumina’s security extends devices life-span. It lowers substitute regularity. Power efficiency improves as a result of minimized heat loss.

Cost-effectiveness grows from long-lasting sturdiness. Preliminary financial investment equilibriums with lowered downtime. Industries prioritize these tubes for important high-temperature processes. Dependability makes certain constant performance sought after applications.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Temperature Alumina Ceramic And Temperature Resistant For Alumina Ceramic Tube

(High Temperature Alumina Ceramic And Temperature Resistant For Alumina Ceramic Tube)

REQUEST A QUOTE

RELATED PRODUCTS

Customization Industrial Insulation High Precision High Purity Ceramics 95% 99% 99.5% Structural Parts Alumina Ceramic

Al2O3 Ceramic mutiple size aluminium oxide ceramic tubes

Ceramic Base Industrial Ceramics 95% Alumina Ceramic Part

Al2O3 Ceramic 6mm,20mm Inert Alumina Ceramic Ball as Catalyst Support Media Ceramic Ball

Long Service Life Materials Made of Ceramics 95 99 Al2o3 Insulator Alumina Ceramic Ring