Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

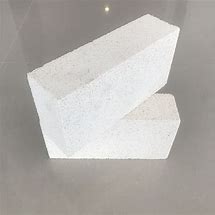

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

( Corrosion Resistance Insulating Al2O3 Alumina Ceramic Plunger Shaft Ceramic Rod Zirconia Ceramic Pipe)

Specifications of Corrosion Resistance Insulating Al2O3 Alumina Ceramic Plunger Shaft Ceramic Rod Zirconia Ceramic Pipe

This line of product includes high-performance ceramic elements designed for requiring commercial applications. The Rust Resistance Insulating Al2O3 Alumina Porcelain Plunger Shaft offers exceptional resilience. It is made from 95% or 99% pure alumina. The material makes sure solid resistance to acids, antacid, and solvents. Running temperature levels rise to 1600 ° C. The surface is smooth, minimizing rubbing during mechanical motion. Its insulation properties avoid electric conductivity, making it optimal for electronics or high-voltage atmospheres. Custom diameters vary from 3mm to 50mm. Lengths vary as much as 500mm based on requirements.

The Alumina Porcelain Rod shares similar material properties. It supplies high solidity, ranked at Hv 1500 or above. Wear resistance expands component life expectancy in unpleasant conditions. Thermal stability stops contortion under quick temperature changes. The rod’s thickness is 3.8 g/cm FIVE, making sure light-weight yet robust performance. Applications consist of semiconductor production, heating system components, and accuracy machinery. Typical sizes span 2mm to 100mm. Sizes are adjustable up to 1000mm.

The Zirconia Porcelain Pipe masters extreme atmospheres. Made from yttria-stabilized zirconia, it incorporates toughness with deterioration resistance. Crack toughness goes beyond 8 MPa · m 1ST/ ², lowering damage dangers. Thermal shock resistance enables sudden shifts from 20 ° C to 800 ° C without breaking. The pipeline’s low thermal conductivity isolates warmth effectively. Readily available in internal diameters from 5mm to 80mm. Wall thickness options array in between 1mm and 10mm. Surface area surfaces achieve Ra ≤ 0.2 μm for precision fluid handling.

These ceramics are chemically inert, staying clear of reactions with metals or hostile media. Electrical insulation ratings surpass 15 kV/mm. All elements go through rigorous quality checks for dimensional precision. Checking consists of firmness confirmation, thermal biking, and leakage discovery for pipelines. Customized shapes or coatings like silicon carbide can be included.

Primary industries offered consist of chemical processing, aerospace, power, and clinical devices. The products meet ISO 6474 and ASTM F2094 standards. Packaging uses anti-static products to prevent contamination. Preparations vary from 1-4 weeks based on order intricacy.

( Corrosion Resistance Insulating Al2O3 Alumina Ceramic Plunger Shaft Ceramic Rod Zirconia Ceramic Pipe)

Applications of Corrosion Resistance Insulating Al2O3 Alumina Ceramic Plunger Shaft Ceramic Rod Zirconia Ceramic Pipe

Corrosion-resistant protecting Al2O3 alumina ceramic bettor shafts, ceramic rods, and zirconia ceramic pipelines are widely utilized in markets requiring longevity and integrity. These materials stand up to harsh chemicals, heats, and mechanical wear. They perform well in settings where metals or plastics fall short.

Alumina ceramic bettor shafts prevail in pumps and valves. They manage aggressive fluids like acids, alkalis, and solvents. Their smooth surface lowers rubbing, boosting efficiency in liquid transfer systems. These shafts are used in chemical processing, pharmaceuticals, and water therapy. Their insulation homes stop electrical conductivity, making them secure for use in electrical devices.

Ceramic rods made from Al2O3 alumina serve in mechanical systems needing high stamina. They sustain hefty loads without flexing or breaking. Applications include accuracy equipment, medical tools, and aerospace parts. The poles endure severe temperatures, preserving stability in heating systems or high-heat commercial processes. Their resistance to oxidation guarantees lasting performance in oxygen-rich setups.

Zirconia ceramic pipelines excel in carrying harsh liquids or gases. They are harder than alumina, suitable for high-impact atmospheres. These pipelines are utilized in oil and gas removal, where they withstand unpleasant slurries and high-pressure problems. Zirconia’s low thermal conductivity makes it perfect for insulating pipes in high-temperature systems. The material’s biocompatibility allows use in clinical implants or lab tools taking care of responsive compounds.

In electronic devices, alumina ceramics protect circuits and elements. They dissipate warmth successfully, shielding sensitive parts from overheating. Zirconia’s wear resistance advantages cutting devices and bearings, minimizing maintenance prices. Both materials are lightweight, decreasing power intake in relocating components contrasted to metal choices.

These porcelains are picked for their mix of solidity, thermal security, and chemical inertness. They prolong devices lifespan sought after applications. Industries depend on them to decrease downtime and replacement costs. Their adaptability sustains development in fields from power production to biomedical engineering.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Corrosion Resistance Insulating Al2O3 Alumina Ceramic Plunger Shaft Ceramic Rod Zirconia Ceramic Pipe

What are corrosion-resistant insulating Al2O3 alumina ceramic plunger shafts? These components are industrial parts made from high-purity aluminum oxide (Al2O3). They resist chemical damage, handle extreme temperatures, and insulate against electricity. Their structure suits pumps, valves, and machinery needing durability in harsh conditions.

Why do Al2O3 alumina ceramic plunger shafts resist corrosion? Alumina ceramic has no reactive metals. It stays stable in acidic, alkaline, or salty environments. This prevents rust or decay common in metal parts. The material’s density blocks chemicals from penetrating the surface.

What temperatures can alumina ceramic rods handle? Alumina ceramic rods work in temperatures up to 1650°C (3000°F). They keep strength and shape under heat stress. This makes them ideal for furnaces, engines, or high-heat industrial processes.

Where are zirconia ceramic pipes used? Zirconia pipes are tougher than alumina. They handle mechanical stress better. These pipes are common in fuel cells, medical devices, or precision equipment needing wear resistance. They perform in both high-pressure and abrasive settings.

What’s the difference between alumina and zirconia ceramics? Alumina offers better insulation and cost efficiency. It’s preferred for electrical systems or budget-focused projects. Zirconia has higher fracture toughness. It suits heavy-load applications like cutting tools or joint replacements. Both resist corrosion but differ in strength and use cases.

( Corrosion Resistance Insulating Al2O3 Alumina Ceramic Plunger Shaft Ceramic Rod Zirconia Ceramic Pipe)

REQUEST A QUOTE

RELATED PRODUCTS

Porous Semiconductor Ceramics/insulating Electronic Ceramics/995 Alumina Ceramics

High Temperature Alumina Ceramic And Temperature Resistant For Alumina Ceramic Tube

Al2O3 Ceramic Large size aluminium oxide ceramic plates and discs Alumina ceramic round plate

Al2O3 Ceramic Hot Selling Refractory Alumina Brick Kiln Rotary Kiln Building Making Clay Brick For Oven

High Strength 99 Alumina Textile Ceramic for Factory Use