Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Boron Nitride Ceramic

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Boron Nitride Ceramic

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

(Aluminum Nitride / Boron Nitride Composite BN-AlN Ceramic Parts for Ion Source)

Specification of Aluminum Nitride / Boron Nitride Composite BN-AlN Ceramic Parts for Ion Source

The BN-AlN composite ceramic components incorporate aluminum nitride (AlN) and boron nitride (BN) in a specific proportion to supply high-performance materials for ion resource applications. This composite merges the advantages of both porcelains. AlN supplies excellent thermal conductivity and electric insulation. BN adds lubricity and thermal shock resistance. The result is a product matched for severe settings where dependability matters.

These ceramic parts manage heats successfully. The thermal conductivity arrays between 180-220 W/mK. This makes sure effective warmth dissipation during ion source operation. Electric insulation protects against existing leak. The dielectric toughness remains steady at 15-20 kV/mm. This minimizes dangers of electrical failure in high-voltage configurations.

BN-AlN compounds operate reliably in temperature levels up to 1800 ° C under inert conditions. They resist deterioration from responsive gases and plasma direct exposure. This makes them perfect for ion sources in etching, deposition, and ion implantation processes. Mechanical stamina continues to be solid under stress and anxiety. Flexural strength measures 300-400 MPa. Solidity reaches 12-15 GPa. These residential properties protect against cracking or contortion throughout usage.

Precision production guarantees limited dimensional resistances. Surface area surfaces are smooth to reduce bit generation in vacuum systems. Custom shapes and sizes are available. Coatings or metallization can be gotten details user interface needs.

These porcelains are used in semiconductor production, aerospace parts, and advanced study devices. They satisfy demands for resilience and performance in rough problems. The BN-AlN composite decreases downtime by lasting longer than traditional materials. Maintenance expenses go down as substitutes end up being less constant.

The product’s low thermal development coefficient prevents deforming during temperature swings. Chemical inertness maintains responses with procedure gases minimal. This keeps ion resource pureness. Personalized options are customized to fit unique system layouts. Testing data supports performance insurance claims. Technical support assists integrate these parts into existing setups.

BN-AlN ceramic components balance thermal monitoring, electrical insulation, and mechanical security. They resolve difficulties in sophisticated markets calling for precision and reliability. Their buildings make them a useful upgrade for enhancing ion source effectiveness and life-span.

(Aluminum Nitride / Boron Nitride Composite BN-AlN Ceramic Parts for Ion Source)

Applications of Aluminum Nitride / Boron Nitride Composite BN-AlN Ceramic Parts for Ion Source

BN-AlN ceramic components incorporate light weight aluminum nitride and boron nitride. This mix produces materials suited for ion sources in demanding setups. These parts handle high warmth well. They maintain their form under extreme temperatures. They insulate electrical power properly. This quits power loss in ion sources. They stand up to chain reactions. This makes them last much longer in destructive environments.

Ion sources require products that take care of warm. BN-AlN ceramics move heat far from critical areas. This protects against overheating. It maintains ion resources secure throughout operation. Semiconductor making usages these parts in plasma etching systems. The ceramics endure hostile gases and high temperatures. They aid produce exact integrated circuits.

Aerospace and defense sectors make use of BN-AlN elements in ion thrusters. These thrusters thrust satellites and spacecraft. The ceramics endure extreme radiation and thermal tension. They make certain reputable thruster performance. Clinical tools like bit accelerators depends on these porcelains. They preserve vacuum conditions. They decrease contamination threats in cancer therapy systems.

Analytical tools benefit also. Mass spectrometers and ion implanters make use of BN-AlN components. The porcelains enhance ion light beam precision. They minimize electrical disturbance. This results in much better information top quality. Manufacturers pick BN-AlN for its mechanical stamina. It resists splits under repeated thermal cycles. This cuts downtime and upkeep prices.

BN-AlN porcelains operate in high-frequency applications. They support steady ion generation in radar systems. Their reduced thermal development matches metals and other porcelains. This allows limited seals in intricate assemblies. The product’s adaptability makes it optimal for custom-made ion source designs. Designers customize sizes and shapes without losing performance.

These ceramics satisfy rigorous industry standards. They execute in vacuum cleaners and high-voltage configurations. Their sturdiness matches research labs and industrial equipments. BN-AlN parts manage fast temperature level shifts. They preserve feature in severe problems. This reliability sustains innovative innovation across areas.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Aluminum Nitride / Boron Nitride Composite BN-AlN Ceramic Parts for Ion Source

What are BN-AlN composite ceramic parts? These parts combine aluminum nitride (AlN) and boron nitride (BN). Both materials have unique properties. AlN offers high thermal conductivity. BN provides excellent electrical insulation. Mixing them creates a material ideal for ion sources. The composite handles extreme heat and resists wear. It works well in high-tech applications.

Why use BN-AlN ceramics in ion sources? Ion sources need materials that manage heat and electricity. BN-AlN parts move heat away fast. This stops overheating. They also block electric currents. This prevents short circuits. The material lasts longer under stress. It keeps ion sources stable and efficient. Many industries prefer this combo for reliability.

Can BN-AlN parts handle high temperatures? Yes. These ceramics work in temperatures over 1000°C. They stay strong when heated. Other materials might crack or warp. BN-AlN keeps its shape. It resists thermal shock. Sudden temperature changes won’t damage it. This makes it safe for intense processes like ion implantation.

Do BN-AlN parts resist corrosion? They do. The composite fights chemical reactions. Harsh gases or plasmas in ion sources cause corrosion. BN-AlN ignores these attacks. Metals or plastics might degrade. BN-AlN stays intact. This reduces part replacement. It cuts downtime and costs.

Are BN-AlN parts customizable? Manufacturers shape them into many forms. Complex designs are possible. Holes, grooves, or thin layers can be added. Sizes vary from tiny components to large plates. Customization fits specific ion source needs. It ensures the part matches the machine perfectly. This improves performance and ease of use.

(Aluminum Nitride / Boron Nitride Composite BN-AlN Ceramic Parts for Ion Source)

REQUEST A QUOTE

RELATED PRODUCTS

High Temperature 99% Boron Nitride Ceramic Tube/Rod/pipe Hexagonal Hot Press Industrial Ceramic Custom Cutting Service Available

High Strength / SIC+BN Composite Ceramic / Boron Nitride Ceramic Plate

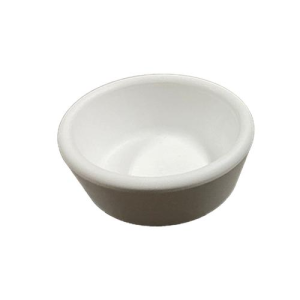

High temperature high purity 99% BN boron nitride crucible

High Temperature BN Composite Boron Nitride Ceramic Crucible Part

BN High purity ceramics boron nitride insulator nozzle