Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Boron Nitride Ceramic

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Boron Nitride Ceramic

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

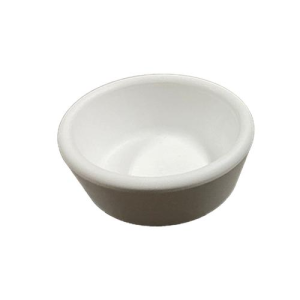

(Soild Hexagonal Boron Nitride BN Ceramic Insulator for High Temperature Furnace)

Specification of Soild Hexagonal Boron Nitride BN Ceramic Insulator for High Temperature Furnace

Strong Hexagonal Boron Nitride BN Ceramic Insulators handle severe warm in high-temperature heaters. These insulators function reliably in environments approximately 2000 ° C. They keep thermal stability under prolonged direct exposure. The hexagonal structure of boron nitride provides reduced thermal growth. This avoids splits during fast temperature level changes. The product remains chemically inert. It resists reactions with molten metals, acids, and alkalis. This prolongs life span in severe conditions.

BN ceramic insulators offer high thermal conductivity. Warm disperses evenly across surface areas. This minimizes hot spots in heating system setups. The material serves as an electric insulator. It protects against current leakage in electrical heating unit. This makes sure safe procedure in high-voltage applications.

Mechanical strength stays solid at elevated temperature levels. The insulator withstands deformation under hefty loads. It supports structural stability in heater components. The product has low rubbing. Parts slide smoothly versus each various other without lubrication. This minimizes wear in moving systems.

BN ceramic is easy to maker. Makers form it right into rods, plates, or personalized geometries. Tight resistances meet details heating system layouts. The material discharges no damaging gases when heated. It fits vacuum cleaner or inert atmosphere furnaces.

These insulators operate in steel handling, semiconductor manufacturing, and aerospace. They manage liquified steel control, crystal growth crucibles, and warm therapy components. The non-wetting surface protects against product adhesion. This simplifies cleansing and upkeep.

Requirement dimensions include diameters from 10mm to 200mm. Density ranges from 5mm to 50mm. Custom-made dimensions are available. The insulator operates in oxidizing environments up to 1000 ° C. Greater temperature levels need nitrogen or argon settings.

Hexagonal boron nitride surpasses conventional porcelains like alumina or zirconia. It combines thermal shock resistance with electric insulation. The material lasts much longer in cyclic home heating applications. Users see lowered downtime and replacement prices.

BN ceramic insulators featured technological assistance for assimilation. Compatibility checks make certain ideal efficiency in existing heating system systems.

(Soild Hexagonal Boron Nitride BN Ceramic Insulator for High Temperature Furnace)

Applications of Soild Hexagonal Boron Nitride BN Ceramic Insulator for High Temperature Furnace

Strong hexagonal boron nitride (BN) ceramic insulators are essential for high-temperature furnace applications. This product handles extreme heat. It stays steady above 2000 ° C. BN withstands thermal shock. Rapid temperature modifications do not crack it. This makes it reliable for duplicated heating cycles.

BN insulators function well in semiconductor production. They protect parts from warmth damages. They stop contamination. BN does not react with molten steels or chemicals. This maintains heating systems tidy. The product’s low thermal development reduces anxiety under heat. This extends devices life.

High-temperature heating systems in aerospace usage BN insulators. They secure sensing units and burner. BN’s high thermal conductivity spreads heat uniformly. This improves heater effectiveness. It additionally conserves energy. The product acts as an electrical insulator. This prevents brief circuits in electrical heating unit.

Metal handling relies upon BN ceramics. They line crucibles for melting alloys. BN does not stay with molten steel. This enables easy removal of cast parts. The product’s lubricating surface minimizes friction. This helps in shaping warm steels. BN stands up to wear. It lasts longer than typical materials like graphite.

Chemical markets use BN insulators in destructive settings. Acids and alkalis do not harm the product. This guarantees safety and security in rough problems. BN works in vacuum cleaner furnaces. It releases very little gas under warm. This preserves vacuum cleaner high quality.

BN ceramic insulators sustain thermocouples and other tools. They offer precise temperature analyses. The material’s insulation residential or commercial properties stop signal interference. This is important for accuracy procedures.

Hexagonal boron nitride incorporates heat resistance with mechanical strength. It surpasses alumina or silica in severe setups. Its versatility makes it perfect for innovative production. Industries take advantage of decreased downtime. Upkeep costs decline. Productivity rises.

BN insulators are machined into customized shapes. This fits particular heating system layouts. The product stays stable under tons. It does not deform at high temperatures. This makes sure consistent performance.

High-temperature heating systems demand products that withstand anxiety. BN ceramics fulfill these needs. They make it possible for advancement in products scientific research. Their use grows in energy, electronics, and heavy industry.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Soild Hexagonal Boron Nitride BN Ceramic Insulator for High Temperature Furnace

What is the maximum temperature solid hexagonal boron nitride ceramic insulators can handle? These insulators work in temperatures up to 1800°C in inert environments. In air, they resist oxidation below 1000°C. This makes them ideal for high-temperature furnaces where metals or other ceramics fail.

Does boron nitride’s high thermal conductivity affect insulation performance? Boron nitride conducts heat well but still insulates electrically. The material’s layered structure traps heat unevenly, slowing transfer. It manages heat distribution without compromising insulation. This balance prevents furnace parts from overheating.

Why is hexagonal boron nitride resistant to thermal shock? The ceramic expands minimally when heated. Sudden temperature changes cause less stress compared to other materials. It handles rapid heating or cooling cycles without cracking. This reliability reduces downtime in furnace operations.

Where are BN ceramic insulators commonly used? They suit semiconductor manufacturing, metal processing, and lab furnaces. Typical applications include crucibles, thermocouple tubes, and protective sleeves. They shield components from extreme heat and corrosive materials. Their stability ensures consistent performance in harsh conditions.

How should BN ceramic insulators be handled and stored? Avoid mechanical impact or rough handling. Store them in dry conditions to prevent moisture absorption. Clean surfaces with alcohol before installation to remove contaminants. Proper care extends service life and maintains insulation efficiency.

(Soild Hexagonal Boron Nitride BN Ceramic Insulator for High Temperature Furnace)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity Boron Nitride Heater Heating Element

Aluminum Nitride / Boron Nitride Composite BN-AlN Ceramic Parts for Ion Source

High Temperature BN Composite Boron Nitride Ceramic Crucible Part

High temperature high purity 99% BN boron nitride crucible

Hexagonal BN Boron Nitride Ring Insulating Ceramic Part