Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

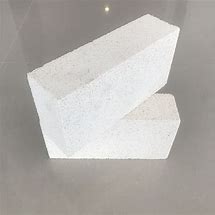

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(High Alumina Ceramic Heater Rod Porcelain Components 95)

Specifications of High Alumina Ceramic Heater Rod Porcelain Components 95

High Alumina Porcelain Heating System Pole Porcelain Components 95 are designed for demanding high-temperature environments. The material contains 95% light weight aluminum oxide (Al2O3). This guarantees exceptional efficiency under extreme conditions. The elements endure temperature levels as much as 1600 ° C. They resist thermal shock properly. Rapid temperature level modifications do not cause breaking or damage. Mechanical stamina is high. The flexing toughness exceeds 300 MPa. This makes them durable under heavy lots. Electric insulation homes are exceptional. They run accurately in high-voltage applications. Surface hardness is superior. It withstands wear and abrasion over long-term use. Chemical stability is an additional key function. Acids and antacids do not wear away the material. This suits extreme commercial settings. The components preserve dimensional stability. They do not flaw under prolonged warmth direct exposure. Thermal conductivity is reduced. Warmth loss is minimized during operation. Custom-made shapes and sizes are readily available. The production process ensures precision tolerances. Surface area finishes can be tailored for particular requirements. Applications include industrial heating systems, kilns, and furnaces. They are made use of in metallurgy, glass production, and chemical processing. The elements incorporate into heating elements and insulation systems. Performance continues to be constant in oxidizing or lowering environments. Installation is uncomplicated. Maintenance requirements are very little. Lengthy service life decreases substitute costs. Compatibility with various other high-temperature materials is made sure. Checking consists of extensive high quality checks. Each batch fulfills market requirements. Technical support is offered for custom options. These components are a reliable choice for high-heat applications.

(High Alumina Ceramic Heater Rod Porcelain Components 95)

Applications of High Alumina Ceramic Heater Rod Porcelain Components 95

High Alumina Ceramic Heater Rod Porcelain Components 95 are extensively made use of in markets requiring high heat resistance and sturdiness. These elements handle extreme temperature levels approximately 1600 ° C. They work well in atmospheres where steels or plastics fail. Their major benefit is security under thermal stress and anxiety. They do not fracture or warp conveniently. This makes them perfect for heater in industrial heating systems.

These ceramic components are common in electric heating tools. They work as heating elements in kilns and ovens. Their high alumina material makes sure effective heat circulation. This lowers energy waste. They likewise last longer than conventional materials. Maintenance costs drop over time.

The electronic devices sector makes use of these elements for insulation. They stop electrical currents from dripping. This improves security in high-voltage devices. Their non-conductive nature safeguards sensitive parts. Gadgets like semiconductors count on their accuracy.

Metallurgical procedures take advantage of these ceramics. They line crucibles and molten metal containers. The product stands up to chemical rust. It remains undamaged when revealed to acidic or alkaline materials. This integrity supports constant production top quality.

Automotive applications include sensing units and glow plugs. The porcelains withstand engine heat and vibrations. They aid modern-day automobiles fulfill exhaust criteria. Their lightweight layout decreases overall element weight.

Medical tools manufacturers make use of these heating unit rods in sanitation tools. They offer clean warmth without contamination. Labs utilize them in high-temperature testing instruments. Accuracy matters here. The ceramics deliver secure efficiency.

These parts are customizable. Shapes and sizes adjust to certain machinery needs. They suit both small-scale tools and huge industrial setups. Their adaptability makes them a practical choice.

High alumina porcelains stand up to wear gradually. They execute in harsh conditions without weakening. This minimizes downtime for replacements. Manufacturing facilities achieve higher efficiency.

The material’s reduced thermal expansion stops structural damages. It stays dimensionally secure under quick temperature adjustments. This is crucial for accuracy design tasks.

Price effectiveness comes from their long service life. Preliminary financial investment settles with minimized substitutes. Industries conserve money while keeping efficiency requirements.

These porcelains support green production. Energy-efficient heating lowers carbon impacts. Business fulfill ecological guidelines a lot more conveniently.

High Alumina Porcelain Heating System Pole Porcelain Elements 95 solve issues in high-heat applications. They incorporate stamina, effectiveness, and adaptability. Their role in modern-day industry continues to grow.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Alumina Ceramic Heater Rod Porcelain Components 95

High Alumina Ceramic Heater Rod Porcelain Components 95 are widely used in high-temperature industrial settings. These components are known for durability and heat resistance. Below are answers to common questions about this product.

What is the maximum temperature these heater rods can handle?

These heater rods work in environments up to 1600°C. The high alumina content (95%) ensures stable performance under extreme heat. This makes them suitable for furnaces and kilns.

Why pick this material over metal heaters?

Metal heaters corrode or deform under high heat. High alumina ceramic resists corrosion and thermal shock better. It lasts longer in harsh conditions. Maintenance costs drop over time.

What industries use these components?

They are common in steel production, glass manufacturing, and semiconductor processing. Labs and research facilities also use them for high-temperature experiments. Their reliability supports precision tasks.

How do I maintain these heater rods?

Avoid rapid cooling after heating. Clean surfaces with a soft cloth to remove debris. Check for cracks or wear regularly. Proper handling prevents damage and extends service life.

Can these components be customized?

Yes. Sizes and shapes adjust to fit specific machinery or applications. Custom holes or threads are possible. Manufacturers test each piece to meet quality standards before delivery.

The material’s high density reduces porosity. This improves insulation and structural integrity. Users report consistent performance even after prolonged use. Compatibility with different heating elements adds versatility.

These answers cover basic concerns. For detailed technical specs or bulk orders, contact suppliers directly. Provide your application requirements for accurate recommendations.

(High Alumina Ceramic Heater Rod Porcelain Components 95)

REQUEST A QUOTE

RELATED PRODUCTS

96 Alumina Ceramic Substrate

Ceramic Base Industrial Ceramics 95% Alumina Ceramic Part

Al2O3 Ceramic mutiple size aluminium oxide ceramic tubes

Ceramic C795 95% Alumina Ceramic Top Smoking Rolling Smoking Accessories

Customized Top Quality Wear Resistant Corrosion Resistant Alumina Zirconia Ceramic Industry Parts