Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Zirconium Dioxide Ceramics

Zirconium Dioxide Ceramics, known for their toughness and ability to withstand extreme temperatures, are widely used in medical, automotive, and industrial applications due to their unique properties.

Features of Zirconium Dioxide Ceramics

Exceptional fracture toughness

High thermal expansion

Excellent resistance to wear and corrosion

Biocompatibility for medical implants

(0.2mm 3mm Yttria Zirconia Dioxide Beads Precision Zirconia Ceramic Grinding Ball )

Specifications of 0.2mm 3mm Yttria Zirconia Dioxide Beads Precision Zirconia Ceramic Grinding Ball

The 0.2mm-3mm Yttria Zirconia Dioxide Beads are precision ceramic grinding rounds designed for high-performance milling applications. Made from yttria-stabilized zirconia dioxide, these beads integrate remarkable hardness with outstanding wear resistance. The product guarantees minimal contamination during grinding, making them perfect for markets calling for ultra-pure results.

These grains include a consistent size range of 0.2 mm to 3mm. The limited dimension resistance warranties consistent fragment size decrease in procedures like wet or dry milling. Their round form boosts grinding efficiency by promoting also exposure to products. This reduces handling time while boosting final product quality.

The zirconia ceramic composition provides high density (over 6.0 g/cm THREE) and crack durability. This permits the beads to endure intense mechanical stress without cracking or deforming. They outshine standard glass or steel grains in resilience, especially in high-speed agitators or upright mills.

Applications include pharmaceuticals, electronic devices, paints, and cosmetics. They excel in grinding delicate products like pigments, inks, or innovative porcelains. The chemical inertness of yttria-stabilized zirconia makes sure compatibility with acidic or alkaline settings. This protects against deterioration or chain reaction throughout long term use.

Surface level of smoothness reduces rubbing between beads and grinding chambers. It decreases warmth generation, maintaining temperature-sensitive compounds. The low porosity structure avoids material adhesion, preserving constant grinding performance over cycles.

Customization alternatives are readily available for size circulation and mass packaging. Each batch undergoes extensive top quality checks for satiation, diameter accuracy, and defect-free surfaces. This guarantees reputable performance in computerized production systems.

These beads are reusable after correct cleansing, using cost effectiveness for large-scale procedures. Their long service life lowers replacement regularity, minimizing downtime and functional prices. Compatibility with typical milling tools streamlines assimilation right into existing workflows.

Industries prioritizing accuracy and pureness benefit most from these zirconia grinding spheres. They deliver fine, consistent particle dimensions critical for innovative products research and premium manufacturing. The combination of mechanical toughness and chemical stability makes them a sensible selection for demanding grinding tasks.

(0.2mm 3mm Yttria Zirconia Dioxide Beads Precision Zirconia Ceramic Grinding Ball )

Applications of 0.2mm 3mm Yttria Zirconia Dioxide Beads Precision Zirconia Ceramic Grinding Ball

0.2mm-3mm Yttria Zirconia Dioxide Beads are tiny ceramic grinding balls used in several industries. These grains help grind materials right into fine particles. They work in makers like round mills or stirrer mills. Their size ranges from 0.2 mm to 3mm. This makes them good for grinding jobs needing precision.

These beads are made from yttria-stabilized zirconia dioxide. The material is extremely hard. It stands up to wear and lasts longer than other grinding media. The grains stay round even after heavy usage. This keeps grinding outcomes regular. They additionally resist chemicals. This makes them risk-free for grinding sensitive materials.

Pharmaceutical companies make use of these grains. They grind active ingredients right into little particles. This boosts drug absorption. Electronic devices makers use them too. They aid make products like battery powders or ceramic finishes. The beads make sure smooth surface areas and also fragment sizes.

Chemical markets rely on these beads for grinding pigments and dyes. The beads stop contamination. They maintain products pure. Cosmetics companies use them to grind powders for make-up. The outcome is great textures that feel smooth on skin.

The beads work well in wet or dry grinding. They take care of high speeds and difficult conditions. Their high density boosts grinding efficiency. Less energy is required to achieve great outcomes. This saves time and costs.

Yttria zirconia beads are steady at heats. They do not broaden or crack under warmth. This makes them trusted for processes entailing warm. They are also non-reactive. This is essential for food or medical items where security matters.

These beads are utilized in labs and manufacturing facilities. They match small experiments and large production. Their dimension range allows flexibility. Users pick the very best dimension for their particular needs.

The reduced wear rate reduces upkeep. Machines remain cleaner longer. Replacement takes place less frequently. This lowers downtime and expenses.

These beads are environmentally friendly. They produce much less waste compared to standard grinding media. Their long lifespan sustains sustainable techniques.

Industries choose these grains for high quality and dependability. They adjust to many materials and procedures. Their performance satisfies high standards. They are a practical solution for accuracy grinding jobs.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 0.2mm 3mm Yttria Zirconia Dioxide Beads Precision Zirconia Ceramic Grinding Ball

What are 0.2mm-3mm Yttria Zirconia Dioxide Beads made of? These beads are made of yttria-stabilized zirconia dioxide. This material is chosen for high wear resistance. It maintains chemical stability under harsh conditions. The structure ensures long-lasting performance in grinding applications.

Where are these zirconia ceramic grinding balls commonly used? They are used in industries requiring fine material processing. Examples include pharmaceuticals, coatings, and electronics. They work in equipment like bead mills or homogenizers. Their role is to grind or mix materials into fine, uniform particles.

What advantages do these beads have over other grinding media? They outperform materials like glass or steel. Their higher density increases grinding efficiency. They wear down slower. This reduces contamination risks. They resist chemical reactions better. This makes them suitable for sensitive processes.

What sizes are available for these zirconia beads? The standard range is 0.2mm to 3mm. Smaller sizes target ultra-fine grinding tasks. Larger sizes handle tougher materials. Size selection depends on desired particle results. Custom sizes can be produced if needed.

How should these grinding balls be stored and handled? Store them in a dry, clean environment. Avoid moisture exposure. Clean beads before use if necessary. Do not mix with other media types. Proper handling extends their lifespan. Follow equipment guidelines for best results.

(0.2mm 3mm Yttria Zirconia Dioxide Beads Precision Zirconia Ceramic Grinding Ball )

REQUEST A QUOTE

RELATED PRODUCTS

High Wear Resistance Zirconia Ceramic Tube ZrO2 Ceramic Pipe

Zirconia AZS Refractory Brick sintered zirconia brick

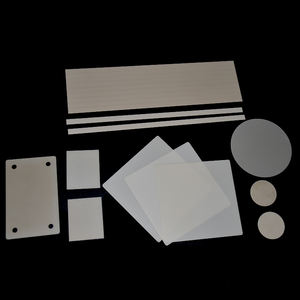

Stabilized Zro2 Zirconia Zirconium Oxide Ceramic Sheet for Sinter

ZrO2 Zirconia Sintering Ceramic Crucible

High Hardness Polished Zirconia Ceramic Plate Zirconium Oxide Porcelain Parts Zro2 Ceramic Sleeve