Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Silicon Nitride Ceramics

Silicon Nitride Ceramics are high-performance materials known for their excellent mechanical properties, including strength, toughness, and resistance to wear, corrosion, and thermal shock, making them ideal for demanding applications in various industries.

Features of Silicon Nitride Ceramics

Exceptional hardness and wear resistance.

Superior mechanical strength and fracture toughness.

Excellent thermal stability and resistance to thermal shock.

High corrosion resistance in aggressive environments.

Low density contributing to lightweight components.

(Industrial Ceramic Rod Application Si3N4 Silicon Nitride Ceramic Strip Stick Bar)

Specifications of Industrial Ceramic Rod Application Si3N4 Silicon Nitride Ceramic Strip Stick Bar

Industrial ceramic rods made from Si3N4 silicon nitride are crafted for demanding commercial settings. These ceramic strips, sticks, and bars excel in high-temperature applications. They maintain structural integrity at temperature levels as much as 1300 ° C. This makes them excellent for furnace components, welding nozzles, and semiconductor processing tools. The material resists thermal shock, taking care of fast temperature changes without splitting. This home makes certain integrity in processes including sudden heating or cooling.

Silicon nitride ceramic poles supply exceptional mechanical strength. They outshine steels and other ceramics in wear resistance. Their firmness lowers deformation under hefty loads. This sturdiness fits them for high-stress functions like bearings, reducing tools, and grinding media. The low density of silicon nitride decreases part weight, improving power efficiency in moving parts.

Chemical security is another essential advantage. Si3N4 resists rust from acids, antacid, and molten metals. This makes it suitable for chemical processing devices, pump seals, and metalcasting parts. The product’s non-reactive nature expands service life in aggressive environments.

Electric insulation homes include adaptability. Silicon nitride ceramic bars prevent electrical conductivity in high-voltage or high-frequency setups. They are used in shielding substrates, sensing unit housings, and digital product packaging. The product’s dielectric strength stays stable across temperature ranges.

Precision machining makes certain tight dimensional tolerances. Custom-made sizes and shapes are achievable for specialized applications. Surface area surfaces can be tailored to minimize friction or boost wear resistance. Industries like aerospace, vehicle, and energy rely upon these poles for vital systems.

Silicon nitride’s biocompatibility opens clinical applications. It offers in medical devices and implantable gadgets. The product’s inertness protects against damaging reactions in biological environments.

Combining thermal, mechanical, and chemical performance, Si3N4 ceramic rods address challenges in innovative manufacturing. Their flexibility supports innovation in fields calling for materials that withstand severe problems.

(Industrial Ceramic Rod Application Si3N4 Silicon Nitride Ceramic Strip Stick Bar)

Applications of Industrial Ceramic Rod Application Si3N4 Silicon Nitride Ceramic Strip Stick Bar

Industrial ceramic poles made from Si3N4 silicon nitride are extensively used in demanding settings. Their heat resistance, strength, and thermal shock stability make them suitable for challenging applications. These poles perform dependably under severe warmth, pressure, and corrosive conditions.

In aerospace, silicon nitride ceramic rods are critical for jet engine parts. Turbine blades and engine components deal with extreme warm and mechanical tension. Silicon nitride manages these conditions without degrading. This lowers wear and expands component life expectancy. Aircraft engines run a lot more efficiently with these products.

The automobile sector benefits from silicon nitride rods in high-performance engines. They are utilized in radiance plugs and turbocharger blades. These parts require materials that stand up to thermal development and exhaustion. Silicon nitride keeps structural stability under quick temperature level changes. This enhances engine efficiency and reduces maintenance demands.

Manufacturing equipment relies on silicon nitride poles for cutting devices and bearings. Traditional metal devices wear down quickly throughout high-speed machining. Silicon nitride uses exceptional hardness and durability. It permits accurate cutting and longer tool life. Bearings made from this material lower rubbing and run smoothly in harsh problems.

Electronics and semiconductor production usage silicon nitride rods as insulators and substrates. They give outstanding electrical insulation and thermal security. Silicon nitride avoids warm damage to sensitive elements. This makes certain trustworthy performance in gadgets like circuit card and sensing units.

Metallurgy applications include molten steel handling. Silicon nitride rods resist deterioration from liquid metals. They are made use of in crucibles and thermocouple tubes. These devices preserve stability in high-temperature steel handling. This enhances security and efficiency in shops.

The clinical area makes use of silicon nitride rods for medical instruments and implants. The material’s biocompatibility and resistance to infection make it ideal for medical gadgets. It stands up to duplicated sterilization without breaking down. This makes sure long-lasting reliability in health care setups.

Silicon nitride ceramic rods are essential throughout markets. Their distinct residential or commercial properties fix challenges in severe environments. They boost efficiency, toughness, and safety in essential applications.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Industrial Ceramic Rod Application Si3N4 Silicon Nitride Ceramic Strip Stick Bar

What is silicon nitride ceramic rod used for?

Silicon nitride ceramic rods handle high-stress environments. They work in parts needing heat resistance and strength. Common uses include bearings, cutting tools, and engine components. They reduce wear and last longer than metal parts.

How does silicon nitride handle high temperatures?

Silicon nitride stays stable up to 1300°C. It keeps strength and shape under heat. This makes it fit for furnaces, turbines, and aerospace parts. It resists thermal shock, so sudden temperature changes don’t crack it.

Why pick silicon nitride over metal or other ceramics?

Silicon nitride beats metals in corrosion resistance. It outperforms other ceramics in toughness. It has low density, cutting weight in machinery. Its self-lubricating surface reduces friction without extra grease.

Can silicon nitride rods be customized?

Yes. Sizes and shapes adapt to specific needs. Common forms include strips, sticks, and bars. Custom machining achieves precise dimensions. Surface treatments improve performance for unique applications.

How to maintain silicon nitride ceramic rods?

Little maintenance is needed. Clean with non-abrasive materials to avoid surface damage. Check for chips or cracks during use. Proper handling prevents breakage from impacts. Storage in dry areas stops moisture-related issues.

(Industrial Ceramic Rod Application Si3N4 Silicon Nitride Ceramic Strip Stick Bar)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity Si3N4 Micron Powder Advanced Ceramic for Grinding Factory Nitride Ceramic Powders Silicon Nitride

Silicon Nitride Plate High Quality Si3N4 Plate Sheet Manufacturer

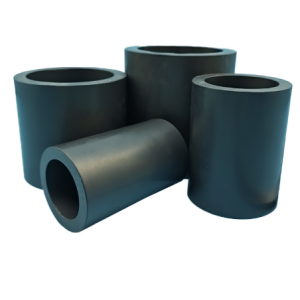

High Strength Black High Temperature Resistance Si3n4 Silicon Nitride Tube Silicon Nitride Ceramic

Silicon Nitride Tube High Hardness And High Strength Si3N4 Tube

High Purity 99.9% Si3n4 Powder Silicon Nitride for Ceramic or Refractory