Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Silicon Nitride Ceramics

Silicon Nitride Ceramics are high-performance materials known for their excellent mechanical properties, including strength, toughness, and resistance to wear, corrosion, and thermal shock, making them ideal for demanding applications in various industries.

Features of Silicon Nitride Ceramics

Exceptional hardness and wear resistance.

Superior mechanical strength and fracture toughness.

Excellent thermal stability and resistance to thermal shock.

High corrosion resistance in aggressive environments.

Low density contributing to lightweight components.

(High Purity 99.9% Si3n4 Powder Silicon Nitride for Ceramic or Refractory)

Specifications of High Purity 99.9% Si3n4 Powder Silicon Nitride for Ceramic or Refractory

High Pureness 99.9% Si3N4 Powder Silicon Nitride is made for advanced ceramic and refractory applications. The product makes sure constant performance popular environments. It features a purity degree of 99.9%, minimizing impurities that influence item high quality. The fragment size varies from 0.5 to 1.5 microns, allowing accurate control in making processes. The powder appears white or light gray, reflecting its uniform composition.

This silicon nitride powder masters thermal security, holding up against temperature levels as much as 1800 ° C without degradation. It maintains stamina and shape under severe warm. The product withstands thermal shock, preventing splits during rapid temperature changes. Its high mechanical toughness sustains heavy tons and rough conditions. The powder demonstrates outstanding rust resistance versus acids, antacid, and molten steels. This ensures longevity in chemically aggressive setups.

The product is ideal for creating high-performance ceramics. Usual usages consist of engine parts, cutting tools, and birthing spheres. It improves wear resistance and resilience in these components. In refractory applications, the powder improves linings for heating systems and activators. It keeps structural stability in metal processing and glass production. Industries like aerospace, automobile, and power count on these buildings for important operations.

Producers benefit from the powder’s compatibility with common creating techniques. It functions well in sintering, warm pressing, and response bonding. The fine fragment size enables dense, uniform sintering. This leads to elements with marginal porosity and high integrity.

The powder is packaged in moisture-resistant, covered containers. This prevents contamination and protects quality throughout storage and transportation. Taking care of adheres to basic security procedures. Customers need to use protective equipment to prevent breathing or skin get in touch with.

High Pureness 99.9% Si3N4 Powder fulfills strict quality criteria. It is tested for uniformity in structure and performance. This ensures it supplies dependable results across commercial applications.

(High Purity 99.9% Si3n4 Powder Silicon Nitride for Ceramic or Refractory)

Applications of High Purity 99.9% Si3n4 Powder Silicon Nitride for Ceramic or Refractory

High pureness 99.9% Si3N4 powder (silicon nitride) is a vital material for sophisticated industrial applications. It is commonly used in ceramics and refractories due to its one-of-a-kind residential or commercial properties. The powder offers outstanding thermal security. It can stand up to severe temperature levels as much as 1800 ° C without deteriorating. This makes it perfect for high-temperature atmospheres like furnace linings or kiln parts. The material also stands up to thermal shock. Sudden temperature changes do not create breaking.

Silicon nitride porcelains are recognized for their mechanical strength. Elements made from this powder are difficult and wear-resistant. They are used in cutting devices, bearings, and engine parts. The low density of silicon nitride reduces weight while keeping sturdiness. This is valuable in aerospace and vehicle sectors.

In refractory applications, Si3N4 powder improves product performance. It boosts resistance to deterioration from liquified steels or chemicals. Crucibles and ladles lined with silicon nitride last much longer. This reduces downtime and maintenance expenses in steel processing. The powder’s high pureness ensures marginal impurities. This avoids contamination in delicate processes like semiconductor manufacturing.

Electric insulation is another crucial function. Silicon nitride ceramics do not conduct electrical energy. They are used in protecting components for digital devices. The product’s dielectric residential or commercial properties sustain high-frequency applications.

The powder is likewise biocompatible. Clinical implants made from silicon nitride stand up to bacterial growth. They incorporate well with human tissue. This is useful for orthopedic and oral applications.

Making high-purity Si3N4 requires sophisticated synthesis methods. Gas-phase reactions or carbothermal reduction make sure consistent quality. The powder’s fine fragment size allows specific shaping during production. Sintering procedures attain dense, trusted ceramic structures.

Industries focus on silicon nitride for its adaptability. It combines warm resistance, mechanical stamina, and chemical inertness. These characteristics attend to difficulties in harsh operating conditions. Designers and manufacturers depend on it to boost product lifespan and performance.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity 99.9% Si3n4 Powder Silicon Nitride for Ceramic or Refractory

What is high purity 99.9% Si3N4 powder?

Silicon nitride (Si3N4) powder is a ceramic material. It has high thermal stability, mechanical strength, and chemical resistance. The 99.9% purity grade means minimal impurities. This makes it suitable for demanding applications like advanced ceramics or refractories.

What are the main uses of silicon nitride powder?

It is widely used in industrial ceramics. Examples include cutting tools, bearings, and engine components. It works in refractory materials for high-temperature furnaces. It is also applied in electronics for substrates or insulating parts. Its durability under extreme conditions makes it popular in aerospace and automotive industries.

Why choose 99.9% purity over lower grades?

Higher purity reduces contamination risks. Impurities weaken material performance. For ceramics or refractories, even small impurities cause cracks or failures under stress. The 99.9% grade ensures consistent results in critical applications. It improves product lifespan and reliability.

How should silicon nitride powder be stored?

Keep it in a dry, cool environment. Moisture causes clumping or unwanted reactions. Use sealed containers to prevent exposure to air. Avoid contact with acids or strong alkalis. Handle with non-reactive tools like plastic or coated equipment. Proper storage maintains powder quality over time.

Is silicon nitride powder safe to handle?

Wear protective gear like gloves and masks. Inhalation of fine particles irritates lungs. Avoid skin contact to prevent dryness or irritation. Work in well-ventilated areas. Follow local disposal guidelines for unused powder or waste. Proper handling minimizes health risks.

(High Purity 99.9% Si3n4 Powder Silicon Nitride for Ceramic or Refractory)

REQUEST A QUOTE

RELATED PRODUCTS

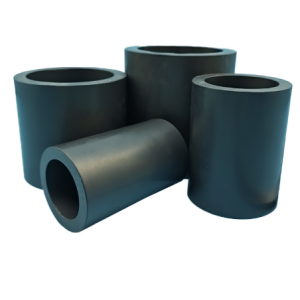

Custom Good Heat Dissipation Chemical Stability Silicon Nitride Si3N4 Ceramic Part Raw Material Tube Sleeve

High Purity Cas No 12033-89-5 Silicon Nitride Powder Si3N4 Ceramic Material 12033-89-5

Wear-resistant Si3N4 / Silicon Nitride Ceramic Plate / Block / Sheet

Silicon Nitride Tube High Hardness And High Strength Si3N4 Tube

Si3N4 Powder High Purity Ultra Fine Silicon Nitride Si3N4 Powder CAS 12033-89-5 Silicon Nitride Si3N4 Ceramic Powder