Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Boron Nitride Ceramic

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Boron Nitride Ceramic

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

(Ceramic Cubic Boron Nitride (CBN) Grinding Wheel Resin-Bonded Universal Joint Ball Cage Gear Disc for Aluminum Compressor Parts)

Specification of Ceramic Cubic Boron Nitride (CBN) Grinding Wheel Resin-Bonded Universal Joint Ball Cage Gear Disc for Aluminum Compressor Parts

The Ceramic Cubic Boron Nitride (CBN) Grinding Wheel with a resin-bonded universal joint ball cage gear disc is made for precision grinding of aluminum compressor components. This wheel combines ceramic CBN grains with a high-strength material bond. The framework makes sure sturdiness and reliable material elimination. The CBN abrasive is more difficult than standard products. It stands up to wear and maintains intensity much longer. This minimizes the demand for constant replacements.

The wheel collaborates with aluminum alloys and non-ferrous metals. It decreases warm accumulation during grinding. This protects against workpiece damages. The global joint sphere cage equipment disc design enables versatile movement. It adapts to complicated shapes in compressor parts. The resin bond supplies a well balanced mix of rigidity and elasticity. It takes in vibrations for smoother operation.

Trick specifications consist of a grain size series of 80-320. Operating speeds reach up to 80 m/s. The wheel size choices are 100 mm to 400 mm. Personalized sizes are available. The ceramic bond boosts thermal stability. This matches high-speed applications. The material matrix ensures constant performance under varying lots.

Advantages consist of extended service life and minimized downtime. The wheel creates fine surface finishes. It takes care of tight tolerances for vital compressor elements. Individuals attain higher performance with reduced energy usage. The style reduces chatter and boosts accuracy.

Applications cover automotive, aerospace, and industrial manufacturing. It is optimal for ending up light weight aluminum rotors, housings, and shutoff plates. The global joint feature sustains tilted or irregular surfaces. This removes the demand for multiple tools.

Proper use needs matching the wheel speed to the machine’s requirements. Routine clothing keeps optimum cutting effectiveness. Operators must look for wear or damage before each use. Storage space in completely dry conditions avoids material bond destruction.

This grinding wheel meets the needs of high-precision aluminum machining. It stabilizes performance, cost, and dependability for commercial grinding jobs.

(Ceramic Cubic Boron Nitride (CBN) Grinding Wheel Resin-Bonded Universal Joint Ball Cage Gear Disc for Aluminum Compressor Parts)

Applications of Ceramic Cubic Boron Nitride (CBN) Grinding Wheel Resin-Bonded Universal Joint Ball Cage Gear Disc for Aluminum Compressor Parts

The ceramic cubic boron nitride (CBN) grinding wheel with a resin bond is made for precision grinding jobs in commercial applications. It functions well for machining light weight aluminum compressor components like global joint ball cage equipment discs. This grinding wheel makes use of ceramic CBN grains, which are very hard and sturdy. These grains remain sharp longer than typical abrasives. This lowers the demand for frequent wheel substitutes. The material bond holds the grains firmly while allowing small flexibility. This combination guarantees smooth material elimination without destructive delicate light weight aluminum surfaces. Light weight aluminum components usually need careful taking care of to avoid bending or overheating. The ceramic CBN wheel creates less warmth throughout grinding. This helps maintain the architectural stability of compressor parts. Universal joint sphere cage equipment discs demand high accuracy. The wheel’s consistent cutting efficiency makes sure tight tolerances and smooth finishes. Material bonds take in resonances throughout high-speed procedures. This lessens surface problems on machined parts. The wheel’s versatility makes it appropriate for both rough grinding and fine completing. It deals with complicated shapes in light weight aluminum compressor assemblies properly. Conventional grinding wheels put on down faster when processing soft steels like aluminum. Ceramic CBN withstands loading, which happens when steel fragments stay with the wheel. This keeps the grinding surface area clean and effective. Less downtime is required for wheel upkeep. Operators achieve higher performance with less interruptions. The wheel’s lengthy life expectancy offsets its first cost with time. Makers benefit from reduced tooling expenditures and improved component quality. Aluminum compressor parts are extensively made use of in automotive and cooling and heating systems. Dependable machining tools are critical for meeting industry standards. The ceramic CBN resin-bonded wheel ensures repeatable outcomes throughout large manufacturing runs. Its style addresses usual challenges in light weight aluminum grinding. These consist of warmth accumulation, product attachment, and device wear. Industries requiring high-precision parts will certainly locate this wheel a practical solution.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Ceramic Cubic Boron Nitride (CBN) Grinding Wheel Resin-Bonded Universal Joint Ball Cage Gear Disc for Aluminum Compressor Parts

Ceramic Cubic Boron Nitride (CBN) grinding wheels resin-bonded universal joint ball cage gear discs are designed for precision grinding of aluminum compressor parts. Below are answers to common questions.

What makes these wheels suitable for aluminum compressor parts?

Aluminum is soft and prone to clogging grinding wheels. The ceramic CBN abrasive resists loading and stays sharp longer. The resin bond allows smooth cutting without overheating the material. This combination ensures efficient material removal and surface finish quality.

How do these wheels compare to aluminum oxide or standard CBN wheels?

Aluminum oxide wheels wear faster and generate more heat. Standard CBN wheels lack ceramic additives for heat resistance. Ceramic CBN wheels last longer, cut cooler, and handle high-speed applications better. They reduce downtime for wheel changes and improve productivity.

Can these wheels be used on other materials besides aluminum?

They are optimized for non-ferrous metals like aluminum. Using them on harder materials like steel may cause premature wear. Check manufacturer guidelines for compatibility. The focus remains on soft metals to maintain performance and wheel life.

What maintenance is required for resin-bonded CBN wheels?

Clean wheels regularly to remove aluminum debris. Use a dressing tool if the surface becomes glazed. Store wheels in dry conditions to prevent resin bond damage. Proper maintenance ensures consistent grinding results and extends wheel lifespan.

What safety precautions are necessary when using these wheels?

Always inspect wheels for cracks before use. Ensure the machine operates within recommended speed limits. Wear protective gear to shield against debris. Secure the workpiece firmly to avoid slippage. Following safety protocols prevents accidents and equipment damage.

(Ceramic Cubic Boron Nitride (CBN) Grinding Wheel Resin-Bonded Universal Joint Ball Cage Gear Disc for Aluminum Compressor Parts)

REQUEST A QUOTE

RELATED PRODUCTS

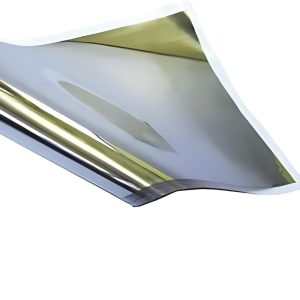

Hot Press Boron Nitride Ceramic Sheet Pyrolytic Boron Nitride PBN Plate / Substrate / Wafer

Hexagonal Boron Nitride Tube Boron Nitride Ceramic Parts

99% 50-100 um Aggregates BN Powder Ceramic Hexagonal Boron Nitride Powder

High Purity BN Insulating Ceramic Plate Boron Nitride Sheet

99.8% 100-200nm Hexagonal Boron Nitride Powder Nano Boron Nitride Powder Ceramic Raw Materials Additive Lubricant