Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Quartz Ceramic Products

Quartz ceramic, also known as fused quartz ceramic or pure silicon ceramic, is an advanced ceramic material made of pure silicon dioxide (SiO₂). It is made by melting high-purity quartz sand at high temperature and then cooling and solidifying it. It has unique physical and chemical properties, making it an ideal choice for many high-tech applications. Quartz ceramic products are widely used in semiconductor manufacturing, optics, electronics, chemical industry and high-temperature industries.

Characteristics and advantages of quartz ceramics

Extremely high thermal stability: Quartz ceramics can remain stable under extreme temperature conditions. They are not only resistant to high temperatures, but also show excellent thermal shock resistance in rapid temperature changes.

Low thermal expansion coefficient: Due to its low thermal expansion coefficient, quartz ceramics have good dimensional stability when the temperature changes and are not easy to deform or crack.

Excellent electrical insulation: Provides excellent electrical insulation performance and is suitable for applications requiring high voltage isolation.

High transparency: It has good light transmittance in a wide band from ultraviolet to infrared, and is particularly suitable for applications such as optical windows and lenses.

Chemical stability: Excellent resistance to most acids, alkalis and other corrosive substances, and almost unaffected by other chemicals except hydrofluoric acid and phosphoric acid.

Mechanical strength: Although quartz ceramic is not as hard as some other types of ceramics, it still has enough mechanical strength to meet the needs of many application scenarios.

High UV transmittance: It has high transmittance in the ultraviolet region, which makes it very useful in UV curing equipment and UV spectrometers.

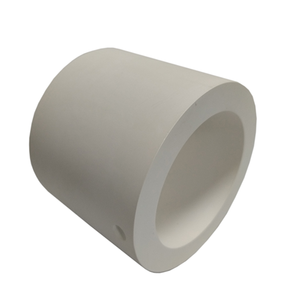

(Long Life Quartz Ceramic Crucible for Casting Refining)

Specifications of Long Life Quartz Ceramic Crucible for Casting Refining

The Long Life Quartz Porcelain Crucible for Spreading Refining is developed for high-performance applications in metalworking and commercial processes. The crucible is made from a special mix of high-purity quartz and advanced ceramic products. This mix makes certain remarkable thermal shock resistance and long term sturdiness under severe temperatures. It runs effectively in atmospheres reaching up to 1750 ° C, making it suitable for melting and refining metals like gold, silver, platinum, and alloys.

The material framework stops cracking or buckling throughout rapid heating or cooling cycles. This reduces downtime and maintenance prices. The crucible’s non-porous surface resists chemical rust from liquified metals, slags, and fluxes. It preserves structural stability also after duplicated usage, ensuring regular efficiency over time.

Offered in multiple dimensions, the crucible accommodates batch capabilities from 50 ml to 5000 ml. Requirement dimensions vary from 50 mm to 300 mm in height, with wall surface density optimized for warmth distribution and energy effectiveness. Custom sizes can be created to fulfill particular task demands.

The smooth indoor finish reduces material bond, simplifying cleanup and reducing contamination risks. Its lightweight layout permits very easy handling while keeping toughness. The crucible works with induction heating systems, gas-fired kilns, and electrical melting systems.

High chemical inertness makes certain marginal interaction in between the crucible and molten products. This protects the purity of refined steels. The product is excellent for accuracy spreading, jewelry making, laboratory study, and industrial foundries.

Safety features include an enhanced base for stability and ergonomic manages for safe transportation. The reduced thermal conductivity of quartz ceramic safeguards tools and operators from too much warm direct exposure. Strenuous quality control examinations verify conformity with global criteria for commercial security and product efficiency.

Each crucible undertakes assessment for defects, guaranteeing uniform density and resistance to thermal tension. The product is packaged firmly to prevent damage during shipping. Replacement regularity is dramatically reduced compared to typical graphite or clay crucibles.

(Long Life Quartz Ceramic Crucible for Casting Refining)

Applications of Long Life Quartz Ceramic Crucible for Casting Refining

Long-life quartz ceramic crucibles play an essential role in spreading and refining procedures. These crucibles deal with severe warmth well. They maintain their form even under heats. This makes them excellent for melting metals like steel, light weight aluminum, and alloys. Manufacturing facilities use them due to the fact that they last longer than standard alternatives. They save cash with time by minimizing replacements.

The crucibles work in high-temperature steel processing. They withstand chemical reactions with molten metals. This maintains the end product pure. Their low thermal expansion prevents fractures during quick home heating or cooling. This reliability is critical for commercial setups.

In rare-earth element refining, these crucibles are crucial. Gold, silver, and platinum need accurate handling. Quartz ceramic materials don’t include impurities. They make certain the refined steel remains high-grade. This is very important for precious jewelry and electronics manufacturing.

Semiconductor manufacturing likewise gains from these crucibles. They take care of silicon and various other products requiring ultra-clean atmospheres. Their non-reactive surface avoids contamination. This assists create trustworthy digital elements.

The crucibles perform well in destructive atmospheres. Acids and antacids do not harm them conveniently. This longevity fits chemical handling sectors. They thaw or mix aggressive compounds safely.

Aerospace and automotive markets rely upon these crucibles. They process innovative alloys for engines and architectural components. Constant performance under stress makes certain reputable output. This supports manufacturing requirements in these areas.

Energy effectiveness is one more advantage. The crucibles heat up promptly. They keep warmth properly. This reduces energy usage throughout prolonged operations. Factories decrease costs while preserving productivity.

Easy upkeep includes in their allure. Deposit doesn’t stick to the smooth surface area. Cleaning up takes much less time. Employees can concentrate on other jobs.

These crucibles fulfill strict industrial needs. Their design balances strength and thermal resistance. They manage everyday usage without breaking down. This makes them a functional selection for modern-day foundries and refineries.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Long Life Quartz Ceramic Crucible for Casting Refining

What materials make Long Life Quartz Ceramic Crucibles durable?

The crucibles use high-purity quartz ceramic. This material handles extreme heat well. It resists cracks from sudden temperature changes. The structure stays stable even after repeated use. This makes it last longer than regular crucibles.

How much heat can these crucibles handle?

They work in temperatures up to 1600°C. The ceramic mix keeps strength under high heat. It avoids melting or warping. This suits jobs like metal refining or glass casting.

Why do these crucibles last longer than others?

Quartz ceramic resists chemical damage. It does not react with metals or slags. Thermal shock resistance stops cracks. Proper care extends their life further. Users save money by replacing them less often.

How do I clean and maintain these crucibles?

Let them cool fully after use. Remove leftover material with a soft brush. Avoid hard tools to prevent scratches. Check for cracks before reuse. Store them dry to avoid moisture damage.

What industries use these crucibles most?

They fit metal foundries, jewelry makers, and labs. Common tasks include melting gold, refining aluminum, or testing alloys. Their heat resistance works for small and large-scale jobs.

(Long Life Quartz Ceramic Crucible for Casting Refining)

REQUEST A QUOTE

RELATED PRODUCTS

Quartz Crucible Melting Dish Ceramic Crucible Bowl for Gold Melting

350 Fused Silica Melting Dishes /quartz Ceramic Crucible Boat Ceramic Melting Crucible

Home Car Air Freshener Decoration Scented Quartz Crystal Stone Colored Ceramic Essential Oil Aroma Diffuser

Glass Tempering Furnace Quartz Fused Silica Ceramic Roller with Good Quality

4-Inch Dry Diamond Polishing Pad 3-Step Ceramic/Tile/Marble/Granite/Quartz Stone for Marble & Granite Surfaces