Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Boron Nitride Ceramic

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Boron Nitride Ceramic

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

(Boron Nitride (R-BN) Used for Making Hot-pressed Ceramic Parts)

Specification of Boron Nitride (R-BN) Used for Making Hot-pressed Ceramic Parts

Boron Nitride (R-BN) is a synthetic ceramic product developed for high-performance applications. It functions well in making hot-pressed ceramic components due to its special homes. The product has high thermal conductivity, allowing heat to move promptly through it. This makes it optimal for environments where temperature level changes swiftly. R-BN stays secure at extreme temperatures, taking care of as much as 2000 ° C in inert environments. In air, it stands up to oxidation approximately 800 ° C, making it dependable for numerous commercial processes.

The chemical stability of R-BN is an additional key feature. It does not respond with many liquified metals, acids, or alkalis. This makes it ideal for usage in corrosive settings. The product also has reduced rubbing, similar to graphite, however carries out much better under high temperatures. Unlike graphite, R-BN is an electrical insulator, adding adaptability in applications calling for non-conductive parts.

Hot-pressed ceramic components made from R-BN show high density and mechanical stamina. The hot-pressing process ensures even circulation of the material, reducing internal defects. This leads to elements that last longer under anxiety. Common uses include crucibles, nozzles, and insulation components in heaters. The material’s thermal shock resistance prevents breaking when temperature levels move suddenly.

Requirements of R-BN include a purity degree of a minimum of 99.5%. Its density ranges from 1.9 to 2.1 g/cm TWO, balancing agility with durability. The thermal conductivity drops in between 20-30 W/m · K, relying on grade and processing. Bit size can be changed during manufacturing to meet details demands. Offered kinds include powders, poles, and custom-shaped components.

R-BN sticks out compared to other ceramics like alumina or silicon nitride. It uses much better thermal monitoring and lubrication buildings. This makes it a leading choice for industries requiring materials that deal with warm, wear, and corrosion. Suppliers value R-BN for producing trusted parts that execute under hard conditions.

(Boron Nitride (R-BN) Used for Making Hot-pressed Ceramic Parts)

Applications of Boron Nitride (R-BN) Used for Making Hot-pressed Ceramic Parts

Boron Nitride (R-BN) is a ceramic product understood for its one-of-a-kind combination of residential properties. It functions well in high-temperature environments. This makes it excellent for manufacturing hot-pressed ceramic components. These parts are used throughout sectors like aerospace, electronic devices, and metallurgy.

R-BN performs heat well yet resists power. This equilibrium is uncommon in ceramics. It helps handle warm in electronic tools. Elements like insulators or heat sinks made with R-BN remain stable also under severe problems. This minimizes overheating risks in circuits or power systems.

The material additionally handles chain reactions without breaking down. It withstands acids, alkalis, and molten steels. This makes it helpful in metal casting. R-BN-coated molds last much longer. They protect against responses in between liquified metal and surface areas. This enhances product quality in production.

R-BN is mechanically strong however light-weight. Hot-pressed parts made from it manage wear and pressure. They are utilized in cutting devices or bearings. These parts last much longer than typical alternatives. This lowers downtime in industrial procedures.

Producing R-BN parts entails hot-pressing powder under high warm and pressure. This method produces thick, consistent frameworks. The process is reliable. It makes sure regular performance in end products. Suppliers like R-BN for accuracy parts. It makers quickly right into complicated forms. This saves time and expenses during production.

R-BN’s convenience sustains advanced modern technologies. It satisfies demands for products that do under tension. Its function in hot-pressed ceramics highlights its worth in modern engineering.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Boron Nitride (R-BN) Used for Making Hot-pressed Ceramic Parts

What is R-BN? Why use it for hot-pressed ceramic parts?

R-BN stands for hexagonal boron nitride. It is a ceramic material with a layered structure. It works well for hot-pressing because it acts as a solid lubricant. This reduces friction during pressing. It also handles heat well. This makes it ideal for shaping ceramics under high temperatures.

How does R-BN improve ceramic parts during production?

Adding R-BN to ceramic powders lowers wear on molds. It stops the material from sticking to tools. This creates smoother surfaces on finished parts. It also spreads heat evenly. This stops cracks or warping. The result is stronger, more consistent ceramic components.

Can R-BN handle extreme heat in hot-pressing?

Yes. R-BN stays stable up to 2,000°C in inert atmospheres. It does not melt or break down. This keeps its lubricating properties even under high heat. It works better than graphite. Graphite burns away in oxygen-rich settings. R-BN lasts longer in tough conditions.

Does R-BN react with metals or ceramics during processing?

No. R-BN is chemically inert. It does not react with most metals or oxides. This prevents contamination. Parts stay pure. It also avoids unwanted chemical bonds. This makes it safe for use with alloys or advanced ceramics like alumina.

Is R-BN expensive? Does it raise production costs?

R-BN costs more than common lubricants like graphite. But it saves money long-term. It extends mold life by reducing wear. It cuts waste from failed batches. It also improves part quality. This lowers costs per unit over time.

(Boron Nitride (R-BN) Used for Making Hot-pressed Ceramic Parts)

REQUEST A QUOTE

RELATED PRODUCTS

Hard High Purity Boron Nitride (BN) Ceramic Parts Customized Industrial Ceramic Components and Precision Machining

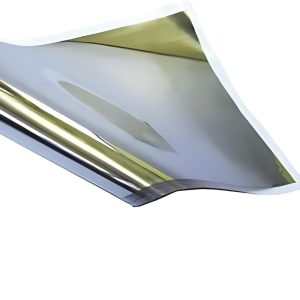

Chemically Stable Boron Nitride Ceramic BN Film

High Temperature 99% Boron Nitride Ceramic Tube/Rod/pipe Hexagonal Hot Press Industrial Ceramic Custom Cutting Service Available

Hot Press Boron Nitride Ceramic Sheet Pyrolytic Boron Nitride PBN Plate / Substrate / Wafer

99% Borazon Boron Nitride Ceramic Bushing Bush Sleeve BN Sealing Ring Cubic boron nitride