Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

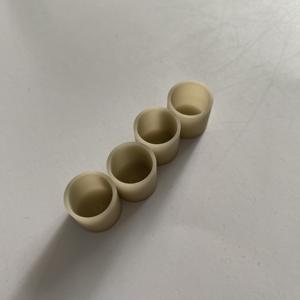

Description

Overview of aluminum nitride ceramics

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of aluminum nitride ceramics

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

(AlN Aluminum Nitride Ceramic Sheet Industrial Parts Aluminum Nitride Ceramic Heater)

Specifications of AlN Aluminum Nitride Ceramic Sheet Industrial Parts Aluminum Nitride Ceramic Heater

AlN aluminum nitride ceramic sheets act as high-performance industrial components. These sheets master thermal monitoring due to their outstanding thermal conductivity. Aluminum nitride ceramic heaters made from this material transfer warm effectively. The thermal conductivity gets to 170-200 W/m · K. This property makes certain rapid heat circulation. It decreases power loss during procedure. High electric insulation avoids existing leak. The dielectric toughness surpasses 15 kV/mm. This makes the material safe for high-voltage settings. The thermal expansion coefficient matches silicon very closely. This compatibility decreases tension in digital applications. Aluminum nitride resists thermal shock. It deals with temperature levels up to 1300 ° C without deformation. The product preserves stability in severe problems. It performs reliably in vacuum cleaner or inert gas ambiences. AlN ceramic sheets display reduced thickness. They evaluate much less than typical metal heating units. This minimizes load on supporting frameworks. The sheets resist chemical deterioration. They hold up against direct exposure to acids, antacid, and molten metals. Surface coating choices consist of brightened or coated treatments. These enhance longevity and efficiency. Custom-made sizes and shapes are available. Producers drill holes or cut patterns to fit certain equipment. Light weight aluminum nitride heaters warmth evenly. They get rid of hot spots typical in steel heaters. This guarantees regular process outcomes. Applications cover semiconductor production. They are used in LED manufacturing, laser diodes, and power modules. The sheets also serve in aerospace and vehicle markets. Their high purity prevents contamination in cleanroom atmospheres. AlN ceramic parts outlast steel choices. They minimize maintenance costs gradually. The material fulfills RoHS and REACH compliance requirements. It sustains eco-friendly commercial practices. Aluminum nitride ceramic heaters integrate quickly right into existing systems. They need no specific installment tools. Individuals report enhanced power performance contrasted to conventional heaters. The sheets operate quietly with no relocating components. This decreases office noise pollution. Heating units made from light weight aluminum nitride launch promptly. They reach target temperatures faster than metal-based devices. This accelerate production cycles. The material’s non-toxic nature makes certain worker security. No unsafe fumes launch during home heating. Aluminum nitride ceramic sheets remain stable under mechanical stress. They stand up to breaking under resonance or influence. This dependability matches hefty machinery applications.

(AlN Aluminum Nitride Ceramic Sheet Industrial Parts Aluminum Nitride Ceramic Heater)

Applications of AlN Aluminum Nitride Ceramic Sheet Industrial Parts Aluminum Nitride Ceramic Heater

AlN light weight aluminum nitride ceramic sheets are extensively made use of in industrial applications due to their unique residential properties. These sheets use high thermal conductivity, superb electric insulation, and solid resistance to warmth and deterioration. They carry out well in extreme settings, making them optimal for requiring commercial tasks.

One vital use is in electronics and semiconductor production. AlN ceramic sheets manage warmth effectively in high-power devices. They prevent overheating in circuits and elements, making sure stable efficiency. Their electric insulation protects sensitive components from damage.

In LED lighting systems, AlN ceramic sheets serve as heat sinks. They draw heat away from LED chips, expanding the lifespan of the lights. This boosts power efficiency and lowers maintenance expenses.

The auto market take advantage of AlN ceramic sheets in electrical automobiles and power modules. They handle heats in battery systems and electronic controls. This dependability supports the shift towards electric transportation.

AlN ceramic heating systems are one more significant application. These heaters give precise temperature control in industrial processes. They operate in semiconductor fabrication, chemical handling, and aerospace testing. Their quick cooling and heating rates enhance performance.

The product’s resistance to chemical corrosion makes it appropriate for rough atmospheres. AlN ceramic parts sustain direct exposure to acids, alkalis, and molten metals. This toughness minimizes downtime in manufacturing.

Medical equipment also utilizes AlN ceramic elements. They ensure safe warmth circulation in devices like imaging systems and surgical tools. Their safe nature satisfies rigorous health care standards.

AlN ceramic sheets are machined into personalized shapes for certain industrial requirements. They work as substratums, insulators, or structural parts in sophisticated equipment. Their convenience supports advancement across several sectors.

Aluminum nitride ceramic heating systems attract attention for their energy effectiveness. They convert electrical energy to warm with very little loss. This lowers functional expenses in factories and labs.

The mix of thermal and mechanical stamina makes AlN porcelains a leading option for high-performance applications. Industries count on them to fix intricate design difficulties. Their function in contemporary innovation remains to grow as demand for efficient, long lasting materials boosts.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of AlN Aluminum Nitride Ceramic Sheet Industrial Parts Aluminum Nitride Ceramic Heater

What are AlN aluminum nitride ceramic sheets used for?

AlN aluminum nitride ceramic sheets work in high-tech industries. They handle extreme heat and electricity. These sheets fit in semiconductor manufacturing, LED production, power electronics. They insulate parts while moving heat away. This stops devices from overheating.

Why pick aluminum nitride for ceramic heaters?

Aluminum nitride moves heat better than most ceramics. It stays stable in high temperatures. It resists chemical damage. Ceramic heaters made with AlN warm up fast. They last longer under tough conditions. This makes them reliable for industrial heating tasks.

How does AlN compare to alumina ceramics?

AlN conducts heat nearly 10 times better than alumina. Alumina works for basic insulation. AlN does both insulation and heat removal. AlN also matches silicon’s thermal expansion. This reduces stress in devices with silicon parts. Alumina costs less but suits lower-performance needs.

What temperatures can AlN ceramic sheets handle?

AlN sheets work from -40°C to over 1800°C. They keep strength and insulation in this range. Short-term spikes up to 2000°C won’t damage them. Regular use stays safe below 1800°C. This suits furnaces, reactors, high-power electronics.

How to handle and store AlN ceramic parts?

Avoid hitting or dropping AlN parts. They resist wear but crack under sharp force. Keep them dry. Moisture weakens them over time. Clean with dry air or soft brushes. Don’t use harsh chemicals. Store in sealed containers with padding. This prevents dust and chips.

(AlN Aluminum Nitride Ceramic Sheet Industrial Parts Aluminum Nitride Ceramic Heater)

REQUEST A QUOTE

RELATED PRODUCTS

Aluminum Nitride Ceramic Sheet Aluminum Nitride Chip Aluminum Nitride Aln Ceramic Plate

Premium Ceramics Product Ultrathin High Temperature Polished Aln Aluminum Nitride Ceramic Substrate Sheet

Insulation Aluminum Nitride Sheet Plate AlN Alumina Ceramic Substrate Plate Tube

AlN Aluminium Nitride Ceramic Sheets / Substrate/plate for Semiconductor

Customized AlN Single Crystal Substrate Aluminium Nitride Plate Ceramic Heater Heating element for Semiconductor Chip Equipment