Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Boron Nitride Ceramic

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Boron Nitride Ceramic

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

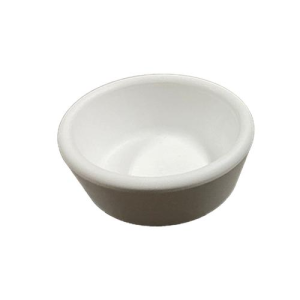

(Insulating Pyrolytic Boron Nitride Wafer Pbn Ceramic Plate)

Specification of Insulating Pyrolytic Boron Nitride Wafer Pbn Ceramic Plate

The Insulating Pyrolytic Boron Nitride Wafer (PBN Ceramic Plate) is a high-performance product made for sophisticated commercial applications. It provides remarkable thermal security, chemical resistance, and electrical insulation. This product is optimal for usage in semiconductor manufacturing, aerospace elements, and high-temperature handling devices.

The wafer is made from pyrolytic boron nitride, an artificial ceramic produced through chemical vapor deposition. This approach makes sure a pure, split structure with uniform residential properties. The product has a thermal conductivity of as much as 60 W/m · K in the planar direction, enabling reliable warmth monitoring. Its thermal development coefficient is reduced, decreasing anxiety under fast temperature level adjustments.

PBN ceramic plates run dependably in temperature levels as much as 2000 ° C in inert or vacuum settings. They resist deterioration from molten steels, acids, and antacid. The material is non-wetting, preventing bond to many compounds. This makes it suitable for crucibles, finishings, and substrates in severe conditions.

The wafer’s electrical insulation residential or commercial properties remain stable throughout a large temperature level variety. It has a dielectric stamina going beyond 10 kV/mm, minimizing risks of electric breakdown. The material’s purity degree goes beyond 99.9%, critical for procedures requiring contamination-free atmospheres.

Offered in custom-made sizes and thicknesses, the wafer can be machined to precise specs. Criterion measurements range from 10 mm to 200 mm in diameter, with density options from 0.5 mm to 10 mm. Surface coatings are customized to application requirements, from as-deposited appearances to sleek finishes.

The PBN ceramic plate is compatible with CVD and MBE systems, acting as a substratum for epitaxial growth. Its transparency to microwave and infrared radiation supports specialized applications in optics and electronics. Mechanical stamina is moderate, needing mindful handling during setup.

This product is made use of in generating LED parts, laser diodes, and semiconductor wafers. Its inert nature protects against reactions with silicon, gallium arsenide, and other materials. Manufacturers value its repeatability in high-precision procedures.

The production procedure ensures marginal porosity and high density. Material residential or commercial properties are consistent across sets. Custom-made doping choices are readily available to change electrical or thermal qualities. Lead times differ based on intricacy, with standard orders delivered within 4-6 weeks.

Examining includes thermal biking, purity analysis, and architectural integrity checks. Certifications adhere to market standards for electronic-grade products. Technical support is attended to assimilation and troubleshooting.

(Insulating Pyrolytic Boron Nitride Wafer Pbn Ceramic Plate)

Applications of Insulating Pyrolytic Boron Nitride Wafer Pbn Ceramic Plate

Shielding pyrolytic boron nitride (PBN) ceramic plates are high-performance products made use of in severe settings. Their special residential or commercial properties make them perfect for innovative industrial applications. PBN ceramic plates offer excellent thermal security. They endure temperature levels over 2000 ° C without breaking down. This makes them appropriate for high-temperature processes like semiconductor production.

PBN plates have reduced thermal development. They keep architectural honesty under rapid temperature level adjustments. This is critical in applications like molecular beam epitaxy (MBE) systems. These systems grow slim films for electronic devices. Home plates make sure exact layer deposition.

Chemical inertness is another vital attribute. PBN withstands reactions with acids, alkalis, and molten steels. It is made use of in crucibles for expanding single crystals. Materials like gallium arsenide require contamination-free settings. PBN avoids undesirable interactions throughout crystal development.

Electrical insulation is crucial in electronics. PBN layers isolate components while managing warm. They are made use of in high-power gadgets like LEDs and laser diodes. Heat dissipation enhances tool efficiency and life-span.

Vacuum systems take advantage of PBN’s ultra-low outgassing. It keeps vacuum cleaner honesty in sensitive tools. This is important precede simulation chambers and analytical instruments.

PBN’s machinability allows personalized forms. It is formed into wafers, tubes, or coatings. This adaptability supports diverse industrial requirements.

The aerospace sector makes use of PBN for sensing units and thermal barriers. It executes dependably in extreme problems. Optoelectronic tools depend on PBN for UV light exhaust. Its openness to ultraviolet light improves performance.

PBN ceramic plates incorporate thermal, electric, and chemical advantages. They attend to difficulties in sophisticated modern technology fields. Their role in enhancing process accuracy and product reliability is unequaled.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Insulating Pyrolytic Boron Nitride Wafer Pbn Ceramic Plate

Insulating Pyrolytic Boron Nitride (PBN) ceramic plates are advanced materials used in high-temperature and vacuum environments. Here are five common questions about these products.

What is a PBN ceramic plate? PBN ceramic plates are made by depositing boron nitride gas onto a substrate under high heat. This process creates a material with high thermal stability and electrical insulation. It is ideal for applications requiring resistance to extreme temperatures and chemical corrosion.

Where are PBN plates typically used? These plates are common in semiconductor manufacturing, especially in processes like molecular beam epitaxy (MBE) or chemical vapor deposition (CVD). They also serve in high-purity environments such as laboratories or aerospace components. Their ability to withstand rapid temperature changes makes them suitable for precision equipment.

How high a temperature can PBN ceramic plates handle? PBN plates operate reliably in temperatures up to 1800°C in vacuum or inert gas settings. In oxygen-rich environments, their limit drops to around 800°C due to oxidation risks. This makes them better for controlled atmospheres compared to standard ceramics.

What advantages do PBN plates have over other ceramics? PBN offers lower thermal expansion and higher thermal conductivity than materials like alumina or quartz. It resists reaction with most metals and acids, ensuring minimal contamination. Its layered structure provides excellent electrical insulation, even under stress. These traits improve process consistency in sensitive applications.

Are there special handling requirements for PBN plates? PBN is brittle. Avoid mechanical shock or sudden temperature shifts. Clean surfaces with non-abrasive methods like alcohol wipes. Store in dry conditions to prevent moisture absorption. Proper handling extends lifespan and maintains performance.

(Insulating Pyrolytic Boron Nitride Wafer Pbn Ceramic Plate)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity Boron Nitride (BN) Ceramic Parts Customized Industrial Ceramic Components And Plates Cutting Processing Service

Soild Hexagonal Boron Nitride BN Ceramic Insulator for High Temperature Furnace

High temperature high purity 99% BN boron nitride crucible

High Purity BN Insulating Ceramic Plate Boron Nitride Sheet

Chemically Stable Boron Nitride Ceramic BN Tube