Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Boron Nitride Ceramic

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Boron Nitride Ceramic

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

(The Erosion-Resistant Sentinel of Chemical Processes – Boron Nitride Ceramic Tube)

Specification of The Erosion-Resistant Sentinel of Chemical Processes – Boron Nitride Ceramic Tube

The Erosion-Resistant Sentinel of Chemical Processes– Boron Nitride Ceramic Tube– stands as a vital part in severe industrial atmospheres. Constructed for extreme conditions, it combines sophisticated product science with useful design. This ceramic tube is made from high-purity boron nitride, a substance known for its special blend of thermal, chemical, and mechanical properties. It operates properly in temperature levels approximately 1800 ° C in inert atmospheres, keeping structural integrity where traditional materials fail.

The product resists attack from the majority of molten metals, acids, and antacid. This makes it excellent for taking care of harsh substances in chemical handling, metallurgy, and semiconductor production. Its non-wetting surface area avoids adhesion of liquified products, lowering contamination dangers. Television’s low thermal growth ensures dimensional security throughout fast temperature level changes, preventing fractures or warping.

Boron nitride ceramic tubes master thermal monitoring. They provide high thermal conductivity, dispersing warm uniformly to avoid hotspots. This home is essential in applications like thermocouple security or high-temperature furnaces. The product also works as an electrical insulator, making it possible for secure usage in electrically energetic environments.

Mechanically, the tube demonstrates remarkable toughness despite its ceramic nature. It endures moderate mechanical tension and abrasion, extending life span in demanding configurations. The smooth surface area coating lessens friction, supporting efficient product flow in applications like liquified steel transfer.

Personalization choices consist of differing sizes, wall surface thicknesses, and lengths to fit details machinery or processes. The material is machinable in its pre-sintered state, permitting precise customizing without endangering performance.

Compatibility with vacuum cleaner systems adds adaptability. Television outgasses minimally under high warmth, maintaining vacuum cleaner integrity in delicate operations. Its light-weight style streamlines installation and minimizes lots on sustaining frameworks.

Environmental resistance covers oxidation approximately 900 ° C in air. For greater temperature levels, optional layers boost oxidation defense. Television meets industry requirements for pureness, making certain no contamination in procedures entailing responsive or high-purity materials.

Maintenance demands are minimal. The product’s integral stability decreases wear, reducing downtime and replacement costs. Industries depending on continual, high-stakes procedures take advantage of its reliability.

Applications cover aerospace, energy, and research fields. Usual usages include crucibles, linings, and protective sleeves. The boron nitride ceramic tube bridges the gap in between severe functional demands and material restrictions, offering a service crafted for resilience.

(The Erosion-Resistant Sentinel of Chemical Processes – Boron Nitride Ceramic Tube)

Applications of The Erosion-Resistant Sentinel of Chemical Processes – Boron Nitride Ceramic Tube

Boron nitride ceramic tubes stand apart as important parts in harsh chemical atmospheres. Their erosion-resistant residential or commercial properties make them optimal for taking care of aggressive materials. These tubes do dependably in chemical handling markets. They withstand harsh acids, liquified salts, and reactive gases. This durability lowers equipment failing threats in important procedures.

Chemical factory use boron nitride tubes in activators and heat exchangers. The product withstands attack from acids like sulfuric acid and alkalis like salt hydroxide. This security ensures lengthy service life also under severe conditions. Semiconductor sectors count on these tubes for high-purity procedures. Boron nitride does not launch pollutants. It preserves tidy atmospheres throughout crystal growth or chemical vapor deposition.

High-temperature applications gain from boron nitride’s thermal shock resistance. The tubes sustain fast temperature modifications without breaking. Metallurgical procedures utilize them for liquified metal handling. Boron nitride does not damp with liquified light weight aluminum or steel. This stops sticking and makes certain smooth material flow.

Electrical insulation is an additional crucial advantage. Boron nitride ceramic tubes stay non-conductive also at elevated temperatures. They work as safety sheaths for thermocouples in heaters. This stops short circuits and prolongs sensing unit life expectancy. Aerospace applications use these tubes in propulsion systems. They manage warm gases and abrasive gas without deteriorating.

The material’s reduced thermal expansion decreases dimensional modifications under heat. This maintains precision in machinery components. Boron nitride’s light-weight nature reduces total system weight. It relieves installation and reduces power expenses in commercial configurations.

Machinability permits custom-made designs for details needs. Tubes can be shaped right into complex geometries without losing efficiency. This versatility fits diverse industrial demands. Cost effectiveness comes from decreased maintenance and replacement requirements. Industries reduce downtime and material expenditures.

Boron nitride ceramic tubes satisfy stringent safety and security requirements. They avoid leaks and spills in harmful processes. Employees benefit from minimized exposure to hazardous chemicals. Ecological dangers lower because of dependable control. These tubes support sustainable procedures by lessening waste.

Study remains to increase their applications. Advancements focus on enhancing pureness and thermal conductivity. Future growths aim to maximize performance in emerging technologies. Industries adopting boron nitride tubes gain a competitive edge through improved performance and reliability.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of The Erosion-Resistant Sentinel of Chemical Processes – Boron Nitride Ceramic Tube

What makes boron nitride ceramic tubes resistant to erosion? Boron nitride ceramic tubes have a unique hexagonal lattice structure. This structure creates strong atomic bonds. These bonds prevent chemicals or abrasive materials from breaking down the surface. Even in harsh environments like high-temperature reactors or corrosive chemical baths, the material stays intact. It doesn’t react with most acids, alkalis, or molten metals. This keeps the tube’s surface smooth and functional over time.

Where are these tubes commonly used? They are ideal for industrial processes involving extreme conditions. Examples include semiconductor manufacturing, metal casting, and aerospace components. They work well in equipment like thermocouple sheaths, crucibles, or protective sleeves. Their ability to handle heat and resist wear makes them suitable for labs, factories, or high-precision engineering setups.

Do boron nitride tubes handle high temperatures? Yes. They withstand temperatures up to 2,000°C in inert atmospheres. They also perform well under rapid thermal cycling. Unlike metals or plastics, they don’t melt or deform under intense heat. This stability comes from the strong covalent bonds in their structure. They transfer heat efficiently while staying electrically insulating.

Can these tubes resist chemical corrosion? Absolutely. Boron nitride is chemically inert. It doesn’t react with most aggressive substances. Acids like hydrochloric acid or bases like sodium hydroxide have little effect. Molten aluminum, iron, or glass also don’t damage the tubes. This makes them reliable in processes where other materials fail quickly.

Are custom sizes or shapes available? Manufacturers often offer customization. Tubes can be made in different lengths, diameters, or wall thicknesses. Complex shapes like flanged ends or tapered designs are possible. This flexibility ensures the tubes fit specific machinery or experimental setups. Customization depends on production methods and the application’s requirements.

(The Erosion-Resistant Sentinel of Chemical Processes – Boron Nitride Ceramic Tube)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity Boron Nitride Heater Heating Element

High Reliability Boron Nitride Ceramics High Toughness Bn Oxide Ceramics Chunk for Nuclear Reactors

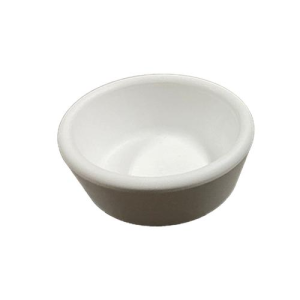

High temperature high purity 99% BN boron nitride crucible

High Purity Easily Machinable Boron Nitride HPBN BN Ceramic Rod

OEM ODM High Precision Boron Nitride Ceramic Structural Parts Advanced BN Ceramic Components According Design