Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

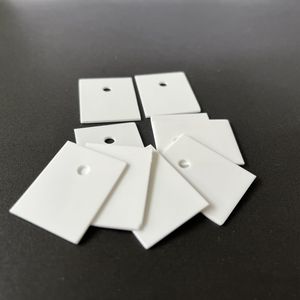

(99% High Strength Alumina Ceramic Substrate)

Specifications of 99% High Strength Alumina Ceramic Substrate

The 99% high-strength alumina ceramic substratum uses superior efficiency in demanding applications. This material contains 99% light weight aluminum oxide, ensuring high purity and dependability. It provides phenomenal mechanical strength, with a hardness score of Hv 1700 or greater. The flexural strength gets to 350 MPa, making it resistant to hefty tons and pressure. This substrate manages severe temperature levels, operating effectively from -50 ° C to 1600 ° C. It shows marginal thermal expansion, keeping stability under rapid temperature modifications. The thermal conductivity procedures 30 W/m · K, enabling efficient heat dissipation.

The product provides superb electric insulation, with a volume resistivity going beyond 10 ^ 14 Ω · cm. It prevents existing leak in high-voltage environments. The dielectric stamina keeps above 15 kV/mm, guaranteeing risk-free operation in electrical systems. Surface level of smoothness is crucial for precision applications. This substrate achieves a surface area roughness listed below Ra 0.2 μm after brightening. Tight dimensional tolerances are maintained, with thickness variants controlled within ± 0.02 mm.

Chemical resistance is an essential attribute. The substratum withstands corrosion from acids, alkalis, and molten metals. It performs well in harsh chemical settings without deteriorating. Put on resistance is exceptional, decreasing worldly loss in unpleasant problems. This expands the element’s service life considerably.

Applications extend multiple industries. Electronics producers utilize it for circuit service providers and insulating components. Commercial equipment relies upon it for wear-resistant linings and reducing tools. The clinical area utilizes it in surgical instruments and implants because of biocompatibility. Laser innovation take advantage of its thermal security in high-power laser components.

Modification options are offered. The substrate can be cut, pierced, or formed to fulfill certain style demands. Metallization layers are added for brazing or soldering requirements. Quality assurance adheres to strict requirements. Each batch goes through strenuous testing for density, porosity, and mechanical properties.

This alumina ceramic outperforms lower-purity options. Greater alumina material enhances hardness, thermal stability, and corrosion resistance. It changes metals in applications requiring electrical insulation and heat resistance. The product fits environments where steel or plastics fall short.

Production makes use of sophisticated sintering strategies. This makes certain consistent microstructure and gets rid of flaws. The outcome is a dense, homogeneous material with constant performance. Technical support is attended to material choice and application style.

This item meets global sector requirements for sophisticated ceramics. It functions as a cost-efficient option for high-performance design challenges.

(99% High Strength Alumina Ceramic Substrate)

Applications of 99% High Strength Alumina Ceramic Substrate

99% high-strength alumina ceramic substratum is a functional product utilized across many sectors. It functions well in electronic devices. Its high electric insulation and thermal security make it optimal for circuit service providers, insulating parts, and sensor elements. It deals with high temperatures and stands up to corrosion. This makes sure devices like smart devices and computer systems stay trustworthy under hefty use.

Industrial equipment gain from this product. It offers in wear-resistant components, reducing devices, and seals. Its solidity and sturdiness reduce friction and prolong devices life. Factories use it in pumps and valves. It endures harsh chemicals and severe heat without damaging down.

Clinical gadgets count on alumina ceramic substrates. They are biocompatible and resist germs. This makes them secure for surgical devices, dental implants, and joint substitutes. The material’s smooth surface area protects against contamination. Health centers use it in imaging equipment as a result of its ability to protect and support.

Automotive systems use the substratum for sensing units and engine components. It stands up to high-pressure settings and temperature level adjustments. Electric lorries utilize it in battery insulation and power components. It improves security by avoiding electrical leakages and handling warmth.

Aerospace applications include thermal shields and communication components. The material’s lightweight nature and strength help in reducing fuel intake. It safeguards satellites and aircraft from severe warmth throughout re-entry. Radar systems use it for stable signal transmission.

Energy industries use alumina ceramic in solar panels and nuclear reactors. It insulates electric systems and withstands radiation damage. Wind wind turbines utilize it in sensors to keep track of stress and temperature level. The material’s security supports long-lasting energy production.

The substrate is likewise used in LED lighting. It dissipates heat effectively, expanding light bulb life. Its reflective buildings boost brightness while minimizing power usage. Makers pick it for high-performance illumination remedies.

Study labs make use of alumina ceramic for high-temperature experiments. Crucibles and labware made from it manage liquified metals and corrosive substances. Its purity prevents contamination in delicate procedures.

Military devices integrates the material for armor and communication devices. Its hardness quits bullets and shrapnel. Radars and rocket systems utilize it to maintain performance under anxiety.

Consumer goods like cooking area home appliances make use of alumina ceramic for heating elements and coatings. It withstands scrapes and warm, enhancing product long life. Cooking equipment and reducing tools gain from its non-stick buildings.

The product’s flexibility and performance make it crucial in modern technology. Industries proceed locating new methods to apply its distinct homes.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 99% High Strength Alumina Ceramic Substrate

1. What is 99% high-strength alumina ceramic substrate? This material is made mostly from aluminum oxide. It is known for being very strong and resistant to heat. It works well in harsh conditions like high temperatures or corrosive environments. People use it in electronics, industrial machines, and medical devices. Its high purity makes it reliable for demanding tasks.

2. What are the main features of this material? It handles extreme heat up to 1600°C without breaking down. It does not conduct electricity, making it safe for electronic parts. It resists wear and scratches even after heavy use. It also resists damage from chemicals like acids or alkalis. These traits make it last longer than many other materials.

3. Where is this ceramic substrate commonly used? It is used in circuit boards for electronics because it insulates well. Factories use it for parts like seals or bearings in machines. Medical tools use it for its non-reactive surface. It is also found in equipment for making semiconductors. Any place needing durability and heat resistance might use this material.

4. How should this substrate be handled during installation? Avoid hitting it with hard objects. Sudden temperature changes can crack it. Use tools designed for ceramics to cut or shape it. Follow the manufacturer’s guidelines for storage. Keep it dry and clean before use to prevent contamination.

5. How does it compare to other ceramic materials? It is stronger than 96% alumina ceramics. It performs better in high-stress or high-heat situations. Metals or plastics might corrode or melt, but this material stays stable. It costs more than lower-grade ceramics but lasts longer. Choose it when reliability matters most.

(99% High Strength Alumina Ceramic Substrate)

REQUEST A QUOTE

RELATED PRODUCTS

Porous Semiconductor Ceramics/insulating Electronic Ceramics/995 Alumina Ceramics

Customized 95% Aluminum Oxide 99% Pure Al2o3 Alumina Precision Ceramic Parts In Tight Tolerance

s Custom Supply Alumina Glazed Ceramic Smoking Accessories

Heat-resistant and Impact-resistant Alumina Ceramics for Sintering Kilns

Polished High Purity 99% Alumina Ceramic Stirring Rods