Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction of Boron Carbide Ceramics

Boron carbide ceramics is an inorganic, non-metallic material with carbon and boron as its main components, and its chemical formula is B4C. Since its discovery in the early 20th century, this material has attracted a great deal of attention because of its unique physical and chemical properties. Boron carbide ceramics have an extremely high hardness, second only to diamond and cubic boron nitride, which makes it important in the field of wear-resistant materials. It also exhibits excellent corrosion resistance, high-temperature stability and low-density properties, attributes that make it ideal for the manufacture of bullet-proof vests, nozzles, bearings and other mechanical components that require high wear resistance. Boron carbide ceramics can also be prepared in a variety of shapes and sizes through different processes to meet the needs of different industries.

Characteristics of Boron Carbide Ceramics

Boron carbide ceramics are known for their excellent performance characteristics, starting with their ultra-high hardness and strength, which makes them resistant to severe abrasion and scratching, making them ideal for use in cutting tools and abrasives. Secondly, the material possesses excellent chemical stability and is less likely to react with chemicals such as acids and alkalis, even in extreme environments, making it widely used in certain key components in the chemical industry. In addition, the superior thermal stability of boron carbide ceramics and their ability to maintain structural and property stability at extremely high temperatures makes them one of the key materials in the aerospace and nuclear industries. Finally, it is worth mentioning its lightweight properties, which, due to its low density, make boron carbide ceramics an ideal option for application scenarios that require light weight but high strength. Together, these characteristics give boron carbide ceramics a wide range of applications.

(Superfine Abrasive Material Boron Carbide F400 F800 B4C Powder China Boron Carbide for Wear Resistance Boron Carbide Ceramic Rod)

Specification of Superfine Abrasive Material Boron Carbide F400 F800 B4C Powder China Boron Carbide for Wear Resistance Boron Carbide Ceramic Rod

Boron Carbide (B4C) Powder is a superfine unpleasant product understood for its extreme solidity and put on resistance. It is widely used in industrial applications requiring longevity and precision. The item is available in F400 and F800 grades, accommodating various surface area finishing and grinding requirements. F400 supplies tool grit for general-purpose abrasion, while F800 provides better bits for smooth, high-precision coatings. Both qualities keep regular bit dimension circulation, ensuring trustworthy efficiency popular settings.

China-produced Boron Carbide Powder is made making use of sophisticated synthesis techniques. This ensures high purity levels (above 98%) and minimal contaminations. The product’s main benefit depends on its exceptional solidity, ranking 3rd after diamond and cubic boron nitride. This makes it excellent for reducing devices, sandblasting nozzles, and safety layers. Its resistance to chemical rust and high-temperature stability (approximately 2200 ° C) more improves its suitability for harsh conditions.

Boron Carbide Ceramic Rods are crafted for wear-resistant applications. These poles are sintered under high stress and temperature level to accomplish thick, crack-free structures. They serve effectively in mechanical seals, birthing parts, and armor plating as a result of their ability to withstand abrasive wear and effect. The poles are customizable in measurements to fit details machinery or tooling requirements.

The powder kind works with thermal spraying and hot-pressing strategies. It bonds well with steels and porcelains, prolonging the life expectancy of covered surfaces. Industries such as aerospace, automobile, and mining count on Boron Carbide for decreasing tools downtime and maintenance costs.

Quality control during manufacturing makes sure batch-to-batch uniformity. Stringent testing procedures verify fragment dimension, chemical make-up, and mechanical homes. This concentrate on standardization fulfills worldwide criteria for industrial abrasives and ceramic elements.

Boron Carbide’s light-weight nature compared to typical metals like steel offers included benefits in weight-sensitive applications. Its combination of reduced density and high strength makes it a favored choice for modern-day engineering solutions.

(Superfine Abrasive Material Boron Carbide F400 F800 B4C Powder China Boron Carbide for Wear Resistance Boron Carbide Ceramic Rod)

Applications of Superfine Abrasive Material Boron Carbide F400 F800 B4C Powder China Boron Carbide for Wear Resistance Boron Carbide Ceramic Rod

Boron carbide (B4C) is a superfine unpleasant product understood for its severe solidity and wear resistance. It rates as one of the hardest materials worldwide, 2nd only to ruby and cubic boron nitride. This makes it optimal for applications calling for resilience under extreme conditions. The F400 and F800 qualities of boron carbide powder offer accurate particle dimensions, making certain consistent performance in industrial usages. These powders are typically utilized in abrasive blowing up, brightening, and surface area therapy procedures where high precision is important.

Boron carbide ceramic poles made from B4C powder are extensively used in wear-resistant parts. Industries like mining, metallurgy, and equipment depend on these poles for parts revealed to hefty abrasion. Examples consist of nozzles, liners, and reducing devices. The ceramic poles preserve structural integrity also at heats, making them suitable for extreme atmospheres. Their low density and high chemical stability even more boost their appeal in aerospace and defense applications.

China-produced boron carbide powders like F400 and F800 are cost-effective without jeopardizing high quality. Suppliers utilize sophisticated handling strategies to make sure pureness and uniformity in the final product. This uniformity is vital for creating trustworthy layers, composites, and sintered components. The powders are additionally used in nuclear reactors as neutron absorbers as a result of boron’s capability to record radiation.

Boron carbide’s resistance to corrosion and mechanical wear lowers downtime in commercial tools. Replacing conventional materials with B4C extends the lifespan of equipment components, lowering maintenance costs. Its convenience covers across sectors, from automotive production to protective armor production. The product’s versatility to different construction approaches enables modification for specific needs.

China continues to be a leading distributor of boron carbide items, supplying competitive prices and scalable production. The accessibility of tailored solutions meets varied industrial demands, guaranteeing worldwide access. Customers take advantage of enhanced performance and reliability in procedures requiring high-performance wear-resistant products.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Superfine Abrasive Material Boron Carbide F400 F800 B4C Powder China Boron Carbide for Wear Resistance Boron Carbide Ceramic Rod

What is boron carbide powder used for? Boron carbide powder is mainly used in industrial applications requiring high wear resistance. It serves as an abrasive material for grinding, polishing, cutting tools. It is also used to produce ceramic components like rods or plates for armor systems, nozzles, blast furnaces. Its extreme hardness makes it suitable for protecting surfaces exposed to friction.

What is the difference between F400 and F800 grades? The F400 and F800 grades refer to particle size. F400 has a coarser grit, averaging 40-50 microns. F800 is finer, around 18-22 microns. Coarser grades like F400 are ideal for heavy material removal. Finer grades like F800 are better for finishing surfaces smoothly. Both grades maintain boron carbide’s hardness and chemical stability.

Can boron carbide ceramic rods handle high temperatures? Yes. Boron carbide ceramic rods resist temperatures up to 2,200°C in inert environments. They keep structural stability under heat. This makes them useful in high-temperature settings like furnace parts or aerospace components. Thermal shock resistance is lower compared to some ceramics, so sudden temperature changes should be avoided.

Is boron carbide powder safe to handle? Boron carbide powder is non-flammable and chemically inert under normal conditions. Direct skin contact might cause mild irritation. Inhalation of fine particles should be avoided. Use protective gear like gloves, masks, goggles during handling. Store in dry, sealed containers away from moisture-reactive substances.

Why choose boron carbide from China? China-produced boron carbide offers competitive pricing without compromising quality. Advanced manufacturing processes ensure consistent particle size distribution and purity levels above 95%. Chinese suppliers meet global standards for industrial abrasives and ceramics. Bulk orders are cost-effective for large-scale projects. Technical support and customization options are often available.

(Superfine Abrasive Material Boron Carbide F400 F800 B4C Powder China Boron Carbide for Wear Resistance Boron Carbide Ceramic Rod)

REQUEST A QUOTE

RELATED PRODUCTS

Silicone Carbide Plates Sic 50X50X6MM 8MM 10MM B4C Ceramic Flat Plate Boron Carbide Plate

China Factory Supply Boron Carbide Ceramic Plate B4C

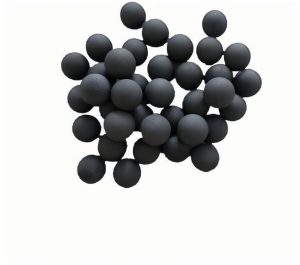

High Purity B4C Boron Carbide Ceramic Grinding Balls

Fine Quality Boron Carbide 99.5% B4C Boron Carbide Ceramic Target for Nanoelectronics

High Strength Hexagonal Boron Carbide Ceramic Tiles B4C Plate