Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Silicon Nitride Ceramics

Silicon Nitride Ceramics are high-performance materials known for their excellent mechanical properties, including strength, toughness, and resistance to wear, corrosion, and thermal shock, making them ideal for demanding applications in various industries.

Features of Silicon Nitride Ceramics

Exceptional hardness and wear resistance.

Superior mechanical strength and fracture toughness.

Excellent thermal stability and resistance to thermal shock.

High corrosion resistance in aggressive environments.

Low density contributing to lightweight components.

(Silicon Nitride Powder Si3N4 Powder Structural Ceramic Materials)

Specifications of Silicon Nitride Powder Si3N4 Powder Structural Ceramic Materials

Silicon Nitride Powder (Si3N4) is a high-performance ceramic material recognized for outstanding mechanical and thermal properties. It works well in extreme problems. The powder has high pureness, typically above 99.9%, guaranteeing dependability in vital applications. Bit sizes vary from nanometers to micrometers, allowing personalization for details uses. The product’s thickness is around 3.2 g/cm FIVE, balancing stamina and weight.

Silicon Nitride provides superb high-temperature stability. It maintains strength at temperatures as much as 1,400 ° C. This makes it perfect for aerospace and generator components. The product stands up to thermal shock, dealing with rapid temperature modifications without breaking. Its low thermal development coefficient decreases tension under warm. Thermal conductivity is modest, preventing warm accumulation in electronic parts.

Mechanical residential properties are outstanding. Silicon Nitride has high hardness, comparable to alumina, and exceptional fracture toughness. It withstands wear and abrasion, prolonging element lifespan. The flexural stamina exceeds 800 MPa, sustaining heavy loads without contortion. Chemical stability is one more crucial feature. It withstands deterioration from acids, alkalis, and molten metals. This matches it for harsh chemical environments.

Electrical insulation residential properties are strong. Silicon Nitride keeps insulation even at high temperatures. This is vital for electronic devices and power systems. The material is compatible with sintering aids like yttria or alumina. These enhance densification during production. Handling approaches include hot pushing, sintering, and additive production.

Applications extend numerous markets. In automotive, it is used for bearings and engine components. Industrial machinery uses it for cutting devices and wear-resistant components. The energy sector uses it in turbine blades and heat exchangers. Electronic devices depend on it for substratums and shielding components. Medical devices benefit from its biocompatibility and durability.

Custom-made grades of Silicon Nitride Powder are offered. Adjustments in structure and fragment dimension satisfy certain requirements. Proper handling ensures ideal efficiency. Storage must remain in dry conditions to stop wetness absorption.

(Silicon Nitride Powder Si3N4 Powder Structural Ceramic Materials)

Applications of Silicon Nitride Powder Si3N4 Powder Structural Ceramic Materials

Silicon nitride powder (Si3N4) is a high-performance ceramic material widely used in sectors needing resilience under extreme conditions. It provides high toughness, thermal stability, resistance to use, and rust. These residential or commercial properties make it suitable for structural parts exposed to high stress and anxiety, temperature level changes, or rough environments.

In auto engineering, silicon nitride powder is used to produce engine components like bearings, valves, and turbocharger rotors. The product decreases rubbing, deals with heats, and resists thermal shock. This improves engine effectiveness and life-span. It functions well in electric car elements, where light-weight products are critical for energy savings.

Aerospace applications benefit from silicon nitride’s ability to stand up to severe warmth and mechanical tension. It is made use of in turbine blades, rocket nozzles, and thermal barrier. The ceramic maintains structural honesty at temperatures exceeding 1000 ° C, making it dependable for propulsion systems and thermal defense.

Electronic devices manufacturing makes use of silicon nitride powder for substrates and insulating components in circuits. Its low thermal expansion and high electrical insulation avoid damage from heat or voltage fluctuations. This ensures stability in tools like semiconductors, sensors, and LED modules.

Industrial machinery counts on silicon nitride for cutting tools, grinding media, and wear-resistant finishings. The product’s hardness and strength prolong device life in metalworking, mining, and precision machining. It minimizes downtime and upkeep prices in heavy-duty operations.

Medical gadgets use silicon nitride for implants and surgical devices due to its biocompatibility and resistance to bacterial growth. Joint replacements and dental implants made from this product incorporate well with bone tissue and reduce infection dangers.

Silicon nitride powder is also used in power markets, such as wind turbine components and nuclear reactor parts. Its resistance to radiation and corrosion supports lasting performance popular environments.

Producers choose silicon nitride ceramic for its versatility and cost-effectiveness. Advanced handling strategies enable intricate shapes and fine-tuned residential properties. This satisfies specific demands across markets while maintaining high performance standards.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Silicon Nitride Powder Si3N4 Powder Structural Ceramic Materials

Silicon nitride powder (Si3N4) is a high-performance ceramic material. It is used in many industries. Here are five common questions about it.

What is silicon nitride powder?

Silicon nitride powder is a fine ceramic material. It contains silicon and nitrogen atoms. The powder is processed into parts through pressing and sintering. It is available in amorphous or crystalline forms.

What are the key properties of silicon nitride?

Silicon nitride has high mechanical strength. It works well in extreme temperatures. It resists thermal shock better than metals. It has low thermal expansion. It resists wear and corrosion.

Where is silicon nitride powder used?

It is used in aerospace for engine components. Automotive industries use it for bearings and valves. Electronics rely on it for insulating parts. Medical devices use it for implants. Industrial tools use it for cutting surfaces.

How does silicon nitride compare to other ceramics?

It is stronger than alumina or zirconia. It handles thermal stress better. It lasts longer in harsh conditions. It is lighter than many metals. It performs well without lubrication.

How should silicon nitride powder be stored?

Keep it dry to avoid moisture absorption. Store in sealed containers at room temperature. Handle with gloves to prevent contamination. Avoid inhaling the powder during processing. Follow safety guidelines for ceramic materials.

(Silicon Nitride Powder Si3N4 Powder Structural Ceramic Materials)

REQUEST A QUOTE

RELATED PRODUCTS

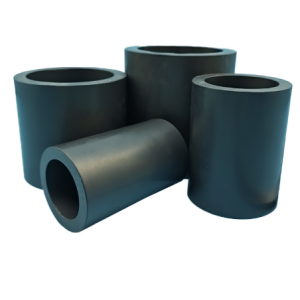

Custom Good Heat Dissipation Chemical Stability Silicon Nitride Si3N4 Ceramic Part Raw Material Tube Sleeve

100-200nm Alpha Si3N4 Silicon Nitride Powders for Ceramic

Silicon Nitride Tube High Hardness And High Strength Si3N4 Tube

High Wear Resistant Gas Silicon Nitride Ceramic Ring

High Polished Si3n4 Silicon Nitride Ceramic Bar and Parts