Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Silicon Carbide Ceramics

Silicon Carbide (SiC) ceramics are renowned for their outstanding mechanical properties, including high hardness, strength at elevated temperatures, and excellent thermal shock resistance. These materials are pivotal in cutting-edge industrial applications, from abrasives to aerospace components, due to their unique combination of properties.

Features of Silicon Carbide Ceramics

High Hardness: Exceptional wear resistance.

Thermal Shock Resistance: Can withstand rapid temperature changes.

Chemical Stability: Resistant to most chemicals.

High Thermal Conductivity: Efficient heat dissipation.

Low Density: Lightweight for its strength.

(Mirror Polish Silicon Carbide Ssic Sic Ceramic Seal Ring)

Specification of Mirror Polish Silicon Carbide Ssic Sic Ceramic Seal Ring

Mirror Gloss Silicon Carbide (SSiC/SiC) Ceramic Seal Ring supplies high efficiency popular commercial settings. The material is sintered silicon carbide, understood for severe firmness and put on resistance. It deals with extreme problems like high temperatures, corrosive chemicals, and hefty rubbing. The ring surface undergoes accuracy mirror sprucing up, accomplishing a smooth coating to reduce leak and make sure tight securing.

This seal ring works in mechanical systems needing trusted securing remedies. Typical applications include pumps, valves, compressors, and revolving equipment. Its low friction coefficient minimizes power loss and extends part life-span. The material resists thermal shock, maintaining stability from -200 ° C to 1600 ° C. It executes well under rapid temperature changes without fracturing.

Silicon carbide ceramics stand up to oxidation and chemical attack. They work in acidic, alkaline, and rough media. The seal ring fits chemical processing, petrochemical, and semiconductor markets. Its high thermal conductivity prevents warm accumulation, protecting nearby components. The structure is non-porous, eliminating contamination dangers in clean environments.

Requirement dimensions vary from 10mm to 500mm internal sizes. Custom-made measurements and geometries are offered. The ring sets well with metals, porcelains, or carbon faces. It outperforms typical materials like tungsten carbide or alumina in sturdiness and efficiency. Installation is uncomplicated as a result of exact resistances and consistent surface coating.

The item minimizes maintenance regularity and downtime. It stands up to high-pressure problems approximately 200 MPa. Electrical insulation homes include security in electrically active arrangements. Put on resistance ensures constant efficiency over thousands of running hours. Mirror polishing lowers surface area roughness listed below 0.1 micron, boosting seal honesty.

Industries like aerospace, automobile, and power depend on this seal ring for critical operations. It satisfies worldwide standards for mechanical seals. Compatibility with aggressive liquids and gases makes it versatile. The absence of lubricating substance reliance supports environment-friendly systems. Long-term price financial savings originated from reduced substitute needs and energy performance.

(Mirror Polish Silicon Carbide Ssic Sic Ceramic Seal Ring)

Applications of Mirror Polish Silicon Carbide Ssic Sic Ceramic Seal Ring

Mirror gloss silicon carbide (SSiC/SiC) ceramic seal rings are crucial in industries needing trustworthy securing under extreme problems. Their high firmness, put on resistance, and chemical security make them suitable for requiring atmospheres. These elements take care of extreme rubbing, pressure, and destructive media without weakening.

The chemical handling market makes use of these seal rings commonly. They stand up to acids, antacid, and solvents. Pump shafts, reactors, and agitators rely on them to prevent leakages. Their smooth surface decreases friction, extending devices life.

In pump and valve systems, mirror gloss SSiC/SiC seals guarantee leak-free procedure. They operate in water treatment, oil and gas, and mining. Their longevity cuts downtime and maintenance expenses. Tough particles in fluids don’t harm them quickly.

Automotive and aerospace applications take advantage of their thermal shock resistance. High-speed engines and wind turbines expose seals to quick temperature level adjustments. Silicon carbide manages heat without cracking. This protects against failings in turbochargers, fuel systems, and hydraulic pumps.

The power sector uses these seals in extreme setups. Wind wind turbines, atomic power plants, and hydroelectric plants need components lasting under stress and anxiety. SSiC/SiC seals endure radiation, high stress, and rough particles. They keep systems running securely.

Semiconductor production requires ultra-clean settings. Mirror polish surface areas protect against contamination. These seals work in vacuum cleaner chambers and etching machines. They stand up to plasma deterioration, making certain process stability.

Food and pharmaceutical industries make use of SSiC/SiC seals for hygiene. Non-porous surfaces quit bacterial growth. They fulfill strict tidiness requirements in pumps and mixers.

Marine devices deals with deep sea deterioration. These seals secure ship engines and offshore boring systems. Salt and dampness do not weaken them. Lengthy life span lowers substitute regularity.

Mirror polish silicon carbide seal rings fix sealing obstacles throughout fields. Their efficiency in difficult conditions makes them a recommended choice for engineers focusing on reliability and effectiveness.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Mirror Polish Silicon Carbide Ssic Sic Ceramic Seal Ring

1. What industries use mirror polish silicon carbide ceramic seal rings? These rings work in pumps, valves, and mechanical systems. They handle harsh conditions like high heat, pressure, and chemicals. Common industries include oil and gas, chemical processing, and wastewater treatment. They fit systems needing reliable sealing with low friction.

2. How does the material handle high temperatures? Silicon carbide stays stable up to 1,600°C in inert gas. In air, it works up to 1,400°C. The mirror polish reduces surface friction. This helps prevent overheating in fast-moving parts. The material keeps strength even under extreme heat.

3. Does it resist chemical corrosion? Yes. Silicon carbide fights acids, alkalis, and oxidizers. It works in corrosive liquids and gases. The non-porous surface stops chemicals from seeping in. This makes it better than metals or polymers in aggressive environments.

4. How long do these seal rings last? Lifespan depends on operating conditions. They outlast traditional materials like carbon or tungsten carbide. Proper alignment and lubrication help. Low wear rates mean less downtime. Regular checks ensure they stay effective.

5. Any tips for installing or maintaining these rings? Avoid impacts during handling. Rough treatment can crack the ceramic. Clean mating surfaces before fitting. Check for scratches or chips. Use compatible lubricants. Follow manufacturer guidelines for pressure limits. Store in dry areas to prevent moisture damage.

(Mirror Polish Silicon Carbide Ssic Sic Ceramic Seal Ring)

REQUEST A QUOTE

RELATED PRODUCTS

High Quality Ceramic Flap Disc Aluminium Oxid Wheel Abrasive Flap Disc OEM for Grinding Silicon Carbide Aluminum Oxide Steel

OEM Customized Refractory Material Sintered Silicon Carbide Ceramic Liner Mechanical Seal Ring

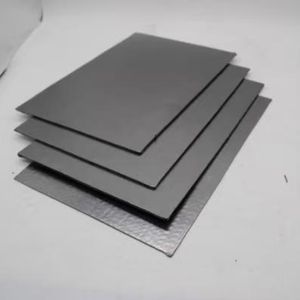

Square Silicon Carbide Ceramic for Ballistic Plate

AL-L Silicon Carbide Ceramic Plate Fish Shape Setter for Firing Dishware Welding Refractory Application

Polymethylsilane Referred to As PMS Is a New Generation Silicon Carbide Ceramic Precursor