Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

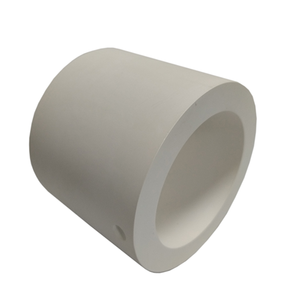

Introduction to Quartz Ceramic Products

Quartz ceramic, also known as fused quartz ceramic or pure silicon ceramic, is an advanced ceramic material made of pure silicon dioxide (SiO₂). It is made by melting high-purity quartz sand at high temperature and then cooling and solidifying it. It has unique physical and chemical properties, making it an ideal choice for many high-tech applications. Quartz ceramic products are widely used in semiconductor manufacturing, optics, electronics, chemical industry and high-temperature industries.

Characteristics and advantages of quartz ceramics

Extremely high thermal stability: Quartz ceramics can remain stable under extreme temperature conditions. They are not only resistant to high temperatures, but also show excellent thermal shock resistance in rapid temperature changes.

Low thermal expansion coefficient: Due to its low thermal expansion coefficient, quartz ceramics have good dimensional stability when the temperature changes and are not easy to deform or crack.

Excellent electrical insulation: Provides excellent electrical insulation performance and is suitable for applications requiring high voltage isolation.

High transparency: It has good light transmittance in a wide band from ultraviolet to infrared, and is particularly suitable for applications such as optical windows and lenses.

Chemical stability: Excellent resistance to most acids, alkalis and other corrosive substances, and almost unaffected by other chemicals except hydrofluoric acid and phosphoric acid.

Mechanical strength: Although quartz ceramic is not as hard as some other types of ceramics, it still has enough mechanical strength to meet the needs of many application scenarios.

High UV transmittance: It has high transmittance in the ultraviolet region, which makes it very useful in UV curing equipment and UV spectrometers.

(Whole CE Certified Cnc Granite Machine Water Jet Cutting Machine for Quartz Plates and Large Ceramic Tiles)

Specifications of Whole CE Certified Cnc Granite Machine Water Jet Cutting Machine for Quartz Plates and Large Ceramic Tiles

The Whole CE Qualified CNC Granite Maker Water Jet Reducing Device takes care of quartz plates and big ceramic tiles with accuracy. It is developed for industrial use. The device fulfills stringent European safety and efficiency requirements. It cuts materials approximately 200mm thick. The reducing precision gets to ± 0.1 mm. This makes certain clean sides and minimal material waste. The maker uses high-pressure water jets mixed with abrasives. The water stress reaches 4200 bar. This enables reducing difficult products like granite, quartz, and ceramics without heat damages. The worktable gauges 3000mm x 2000mm. It sustains large tiles and pieces. The CNC system automates reducing courses. Operators input creates via CAD files. The device reads formats like DXF and DWG. The user interface is straightforward. Training is quick for brand-new individuals. The maker consists of a double pump system. This maintains consistent stress during long jobs. The cutting head readjusts instantly. It stays at the optimal height above the product. The device minimizes noise and vibration. This shields both the driver and the devices. Maintenance is simple. The almosts all come for cleansing and repair work. Safety functions consist of emergency quit buttons, safety covers, and water leakage sensing units. The framework uses durable steel. This makes certain stability throughout high-speed cutting. The device operates in workshops or manufacturing facilities. It links to typical power products. Energy usage is optimized. Running expenses stay reduced. Technical support is readily available 24/7. Spare parts ship internationally. An one-year service warranty covers manufacturing problems. Prolonged service warranties are optional.

(Whole CE Certified Cnc Granite Machine Water Jet Cutting Machine for Quartz Plates and Large Ceramic Tiles)

Applications of Whole CE Certified Cnc Granite Machine Water Jet Cutting Machine for Quartz Plates and Large Ceramic Tiles

The CE-certified CNC granite maker water jet cutting equipment offers high precision for shaping quartz plates and large ceramic tiles. This equipment fulfills rigorous European safety and performance criteria. It uses a high-pressure water stream combined with rough particles to reduce hard products smoothly. The process leaves tidy sides without fractures or warmth damages. Industries like building and construction and interior design rely on this innovation for accurate results.

Quartz kitchen counter manufacturers gain from the device’s capacity to produce elaborate layouts. It manages intricate curves and angles easily. This makes sure minimal material waste during production. Huge ceramic tiles utilized in flooring or wall surface cladding are cut to precise sizes. The equipment adapts to differing densities, keeping consistency across batches. Custom forms for mosaics or decorative patterns are possible without hand-operated adjustments.

The CNC system allows drivers to program comprehensive reducing courses. Styles posted using software application ensure repeatability for mass orders. This minimizes human error and speeds up project timelines. Upkeep is simple due to the equipment’s long lasting parts. It operates silently, making it suitable for workshops with restricted space or sound constraints.

Contractors installing quartz surface areas in kitchens or shower rooms value the device’s accuracy. Limited joints and smooth edges boost the final appearance. For ceramic tile vendors, quick turnaround times fulfill tight target dates. The water jet technique avoids dust production, making sure a cleaner workplace.

Industrial makers utilize this equipment to procedure materials for durable applications. Engineered stone products and commercial porcelains preserve architectural honesty after reducing. The absence of thermal distortion protects worldly toughness. This makes the maker ideal for elements needing rigorous tolerances.

Businesses buying this technology see boosted efficiency and lowered costs. The CE accreditation assurances conformity with global guidelines. Operators call for marginal training to manage the user-friendly user interface. Convenience throughout products and applications makes the equipment a useful choice for diverse industries.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Whole CE Certified Cnc Granite Machine Water Jet Cutting Machine for Quartz Plates and Large Ceramic Tiles

1. What does the CE-certified CNC granite machine water jet cutter do?

The machine cuts quartz plates and large ceramic tiles. It uses high-pressure water mixed with abrasives. This method creates precise shapes without heat. It works on slabs up to 3 inches thick. The process keeps materials strong and avoids cracks.

2. Why is CE certification important?

CE certification means the machine meets European safety and environmental standards. It ensures the design follows strict rules. This reduces risks during operation. Buyers trust CE-marked equipment for quality and reliability.

3. How accurate is the cutting?

The machine cuts within 0.1 mm tolerance. Advanced software controls the water jet’s path. This guarantees clean edges and exact dimensions. No extra polishing is needed. It handles complex designs easily.

4. What maintenance is required?

Check water filters and abrasive levels daily. Lubricate moving parts weekly. Inspect high-pressure seals every month. Replace worn nozzles and hoses as needed. Annual professional servicing keeps it working well.

5. Is the machine cost-effective?

Initial costs are higher than traditional tools. It saves money long-term. Labor costs drop because one operator can run it. Material waste is minimal. Lower energy use cuts bills. CE certification adds resale value.

(Whole CE Certified Cnc Granite Machine Water Jet Cutting Machine for Quartz Plates and Large Ceramic Tiles)

REQUEST A QUOTE

RELATED PRODUCTS

Factory Direct Melting Furnace Crucible Ceramic Crucible / Quartz Crucible

Blue Quartzite Brazil Natural Transparent Stone Luxurious High-end Hotel Decoration Customize Marble Tile

Factory Whole Soft Quartzite Plate Stone Skin Soft Porcelain Ultra-thin Matte Granite

50ml Quartz Silica SiO2 Ceramic Crucible Cylindrical Genre Crucible

Promotion Quartz Solid Surface Book Case Board Stone Tile Design Sample Case Catalog Paint Template Display Rack