Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of aluminum nitride ceramics

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of aluminum nitride ceramics

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

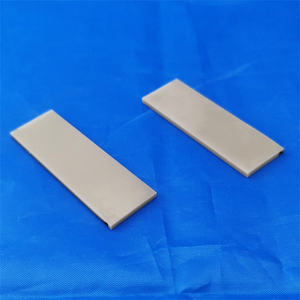

(ALN Substrate 1001002mm Thickness Aluminum Nitride Ceramic Board)

Specifications of ALN Substrate 1001002mm Thickness Aluminum Nitride Ceramic Board

The ALN Substratum is a high-performance aluminum nitride ceramic board developed for demanding technical applications. The item measures 100mm by 100mm with a density of 2mm. Aluminum nitride (AlN) is an innovative ceramic product understood for its exceptional thermal conductivity. This substrate offers a thermal conductivity ranking of 170-180 W/mK. This residential property makes it ideal for heat dissipation in electronic gadgets. The product keeps security throughout a wide temperature array. It executes accurately from -40 ° C to +300 ° C. Electrical insulation is an additional key attribute. The dielectric strength goes beyond 15 kV/mm. This ensures secure operation in high-voltage settings. The board has low thermal development. Its coefficient of thermal development very closely matches silicon. This compatibility reduces stress in semiconductor applications. Mechanical resilience is strong. The flexural toughness gets to 300-400 MPa. Surface area coating is specific. The substratum has a smooth, level surface with a roughness standard (Ra) listed below 0.4 μm. This sustains exact element installing. Chemical resistance is superb. The product stands up to most corrosive gases and liquified steels. No reactions occur with acids or alkalis at room temperature. The aluminum nitride ceramic board is metallization-ready. It accepts thin-film or thick-film finishings for circuit assimilation. Applications include power electronic devices, LED modules, and RF elements. The substrate suits high-frequency systems as a result of reduced signal loss. Its thermal administration capacities profit laser diodes and IGBT modules. Modification options exist for different geometries or surface treatments. The item fulfills RoHS and REACH conformity criteria. Packaging makes use of anti-static materials to prevent contamination. Taking care of recommendations include making use of handwear covers to stay clear of surface area fingerprints. Storage problems require completely dry settings below 30 ° C. Lead time for common dimensions is 5-7 service days. Bulk orders obtain reduced prices. Technical assistance assists with assimilation challenges. Efficiency screening data is readily available upon demand.

(ALN Substrate 1001002mm Thickness Aluminum Nitride Ceramic Board)

Applications of ALN Substrate 1001002mm Thickness Aluminum Nitride Ceramic Board

The ALN Substratum 100 100 2mm ceramic board is made from light weight aluminum nitride. It functions well in high-temperature setups. This material transfers heat efficiently. It also resists deterioration and power. These characteristics make it useful throughout sectors.

Electronic devices manufacturing usages this board for heat management. High-power devices like amplifiers and processors produce warmth. The board relocates warm far from components. This protects against getting too hot and maintains gadgets running longer.

LED lights systems rely on the board’s thermal control. LEDs create warm throughout usage. The board soaks up and spreads this warm. This decreases temperature level stress and anxiety on LED components. It helps maintain brightness and color gradually.

Automotive and aerospace applications require materials that take care of tough problems. The board makes it through extreme temperature levels and vibrations. It operates in electrical car power systems and aircraft sensing units. Its toughness makes sure reliability in critical systems.

Industrial home heating tools uses the board for insulation. Furnaces and heating units operate at high temperatures. The board serves as an obstacle between heating elements and various other components. It resists chemical damage from gases or liquified metals. This extends tools life and safety.

The board’s flat surface sustains accuracy in manufacturing. It serves as a base for reducing or laser work. Its stability prevents buckling under stress. This accuracy is vital for creating little electronic components.

Medical gadgets take advantage of the board’s electric insulation. Tools like imaging systems and medical tools need safe products. The board blocks unwanted currents. It guarantees client and gadget safety and security during treatments.

Solar power systems utilize the board in inverters and converters. These parts handle power flow and generate heat. The board’s warmth transfer capacity keeps systems efficient. It sustains regular energy output in photovoltaic panels.

The ALN ceramic board combines stamina and functionality. Its small dimension fits different tools styles. Industries pick it for performance sought after settings.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of ALN Substrate 1001002mm Thickness Aluminum Nitride Ceramic Board

What is the ALN Substrate 1001002mm Aluminum Nitride Ceramic Board used for? This ceramic board handles high-power electronics. It works in LED lighting, semiconductor modules, and power devices. It manages heat well. It stops components from overheating. It keeps systems stable under stress.

How does Aluminum Nitride compare to alumina ceramics? Aluminum Nitride conducts heat better. It moves heat faster than alumina. It suits high-frequency circuits. It resists corrosion better. It lasts longer in harsh conditions.

What temperature can this ceramic board withstand? It handles up to 850°C in air. It works in inert gases up to 2300°C. It stays strong under heat. It doesn’t crack easily. It’s reliable for extreme environments.

Can this board be customized for specific shapes or holes? Yes. Laser cutting drills precise holes. Machining creates grooves or edges. Custom sizes are possible. Surface finishes are adjustable. Tell suppliers your needs early.

Is Aluminum Nitride safe for electronics? Yes. It doesn’t conduct electricity. It insulates circuits effectively. It doesn’t react with metals. It prevents short circuits. It meets safety standards for industrial use.

(ALN Substrate 1001002mm Thickness Aluminum Nitride Ceramic Board)

REQUEST A QUOTE

RELATED PRODUCTS

High Thermal Conductivity / Aluminum Nitride / AlN Ceramic Substrate/ Plate / Block

Manufacturing AIN Aluminum Nitride Ceramic Discs Aluminum Nitride Disk

High Power Watt AlN Heater Aluminum Nitride Ceramic Heating Element

180W/m.K High Thermal Conductivity High temperature and High humidity Aluminum nitride aln Ceramic Heat Sink Sheet

Customizable 170W Aluminium Nitride Ceramic Roller ALN Parts Insulator for Electronic