Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of aluminum nitride ceramics

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of aluminum nitride ceramics

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

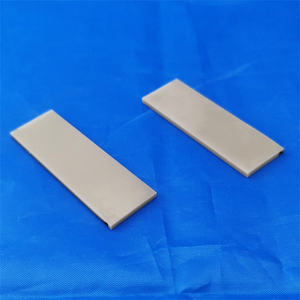

(Factory Direct High Thermal Conductivity Aluminum Nitride ALN Ceramic thermal insulator for High-power Circuits)

Specifications of Factory Direct High Thermal Conductivity Aluminum Nitride ALN Ceramic thermal insulator for High-power Circuits

Factory Straight High Thermal Conductivity Aluminum Nitride (ALN) Ceramic thermal insulators take care of heat successfully in high-power circuits. These materials transfer heat rapidly. They protect against overheating in electronic elements. ALN ceramics carry out far better than traditional alumina porcelains. Alumina has a thermal conductivity of 20-30 W/mK. ALN provides 170-200 W/mK. This makes ALN suitable for requiring applications.

ALN porcelains protect power effectively. They obstruct unwanted existing flow. This protects sensitive circuits. They function accurately in high-voltage settings. ALN withstands physical wear. It maintains toughness under mechanical anxiety. This reduces damage risks. It expands component life expectancy in extreme conditions.

ALN takes care of extreme temperature levels. It runs between -50 ° C and 1000 ° C. It remains stable throughout quick temperature shifts. This suits automobile and aerospace industries. The material expands minimally under heat. It stays clear of splitting or contorting. This makes certain constant performance in time.

The surface coating of ALN porcelains is smooth. It permits limited contact with other parts. This enhances warmth transfer effectiveness. Custom sizes and shapes are available. Producers tailor items to fit particular layouts. This versatility fulfills diverse design needs.

ALN porcelains are chemically inert. They stand up to deterioration from acids and alkalis. They operate in reactive atmospheres without breaking down. This dependability suits industrial and laboratory settings.

These porcelains are used in LED illumination systems. They cool high-power LEDs successfully. They appear in semiconductor manufacturing. They protect and cool down high-frequency tools. They sustain power components in electric lorries. They handle warm in renewable resource systems like solar inverters.

The product is light-weight. It lowers total system weight. This advantages mobile electronics and aerospace applications. ALN ceramics are machined specifically. They integrate flawlessly right into intricate settings up.

Factory-direct prices guarantees cost efficiency. Bulk orders receive affordable rates. Quality assurance fulfills global requirements. Each set undertakes strenuous screening. This ensures regular thermal and electric performance.

ALN ceramics reduce power loss. They enhance gadget performance. They lower maintenance expenses. They prolong devices longevity. These benefits make them a sensible choice for modern-day high-power electronics.

(Factory Direct High Thermal Conductivity Aluminum Nitride ALN Ceramic thermal insulator for High-power Circuits)

Applications of Factory Direct High Thermal Conductivity Aluminum Nitride ALN Ceramic thermal insulator for High-power Circuits

Manufacturing Facility Straight High Thermal Conductivity Aluminum Nitride (AlN) Ceramic thermal insulators are important for managing warmth in high-power circuits. These elements master environments where temperature control is vital. Light weight aluminum Nitride stands out due to the fact that it moves warm far from electronic components promptly. This protects against getting too hot and makes certain steady performance. High-power circuits create considerable warm throughout operation. Without appropriate insulation, this heat can damage parts or minimize efficiency. AlN porcelains solve this issue efficiently.

The material integrates high thermal conductivity with solid electrical insulation. This dual capability makes it suitable for power electronics. Instruments like IGBT modules, MOSFETs, and high-frequency circuits take advantage of AlN’s residential or commercial properties. It moves warmth away from energetic locations while blocking electrical leak. This improves device dependability and lifespan.

Aluminum Nitride porcelains likewise stand up to severe problems. They handle heats without breaking down. They function well in harsh setups or under thermal tension. This resilience suits industries such as aerospace, automobile, and renewable resource. For example, electric lorries make use of AlN insulators in battery systems and power converters. The product guarantees parts remain great also throughout heavy use.

LED illumination systems count on AlN ceramics also. High-power LEDs produce extreme warm in compact areas. AlN substrates assist dissipate this warm successfully. This prevents brightness loss and extends LED life. In a similar way, RF and microwave tools make use of AlN for thermal management in interaction systems.

Semiconductor production equipment often includes AlN parts. The product’s security under heats supports procedures like chemical vapor deposition. It keeps precision in severe production environments.

Factory Straight AlN ceramics provide expense benefits. Getting rid of middlemen minimizes costs. Customized shapes and sizes are readily available to satisfy details design needs. This adaptability guarantees compatibility with diverse applications. High-purity AlN porcelains satisfy stringent industry requirements for efficiency and safety.

The need for efficient thermal monitoring grows as electronics become more powerful. Light weight aluminum Nitride ceramics provide a reputable option. Their special buildings attend to heat-related obstacles throughout several fields.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Factory Direct High Thermal Conductivity Aluminum Nitride ALN Ceramic thermal insulator for High-power Circuits

(Factory Direct High Thermal Conductivity Aluminum Nitride ALN Ceramic thermal insulator for High-power Circuits)

REQUEST A QUOTE

RELATED PRODUCTS

Excellent Thermal Conductivity Aluminium Nitride AlN Ceramic Substrate

CNC Machinable Insulated AlN Aluminum Nitride Ceramic Tube

Excellent Thermal Conductivity Aluminium Nitride AlN Ceramic Substrate

Industry Electrical CNC Machining Ceramic Component Aluminum Nitride Ceramic ALN Heat Sink

Aluminum Nitride Ceramic Sheet Aluminum Nitride Chip Aluminum Nitride Aln Ceramic Plate