Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of aluminum nitride ceramics

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of aluminum nitride ceramics

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

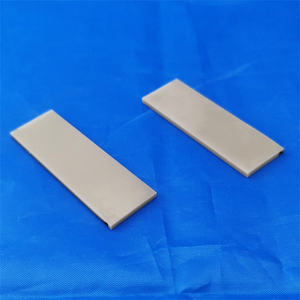

(High Thermal Conductivity Aln/Aluminum Nitride Ceramic Substrate)

Specifications of High Thermal Conductivity Aln/Aluminum Nitride Ceramic Substrate

High Thermal Conductivity AlN/Aluminum Nitride Ceramic Substrate offers innovative performance for demanding digital applications. The material integrates high thermal conductivity with strong electrical insulation. It matches high-power gadgets, LED lights, and semiconductor modules.

Thermal conductivity gets to 170-200 W/mK. This value surpasses typical alumina ceramics. Effective warm dissipation safeguards delicate components. System reliability boosts in high-temperature environments.

The coefficient of thermal development matches silicon. Tension from temperature changes lowers. Bonding with silicon chips remains steady. Tool life expectancy prolongs under thermal biking.

Electrical insulation surpasses 15 kV/mm. High-voltage applications run safely. Leak currents decrease. Performance remains constant in humid or infected conditions.

Mechanical stamina reaches 300-350 MPa. The substratum stands up to fracturing under mechanical stress. Handling throughout setting up simplifies. Long-term toughness satisfies commercial standards.

Surface smoothness achieves 0.1-0.3 μm roughness. Thin-film circuits down payment equally. Laser drilling and precision machining job well. Element combination enhances without surface area problems.

Running temperature endures up to 1000 ° C. Thermal destruction slows. High-temperature procedures like sintering or brazing adapt. Stability maintains in extreme problems.

Aluminum nitride stands up to most chemicals. Deterioration from acids or alkalis prevents. Harsh industrial atmospheres suit the material. Maintenance costs lower gradually.

Customized shapes and sizes are available. Density varieties from 0.25 mm to 3.0 mm. Laser cutting or grinding dressmakers dimensions. Application-specific layouts support adaptable engineering requirements.

The substrate operates in RF and microwave systems. Signal loss reduces as a result of reduced dielectric constant. High-frequency performance enhances communication tools.

Metallization layers like copper or gold apply conveniently. Soldering and cable bonding enhance. Electric connections stay durable under thermal anxiety.

AlN ceramic substratums satisfy ROHS and REACH standards. Ecological regulations comply. International markets accept the product without limitations.

(High Thermal Conductivity Aln/Aluminum Nitride Ceramic Substrate)

Applications of High Thermal Conductivity Aln/Aluminum Nitride Ceramic Substrate

High thermal conductivity AlN/aluminum nitride ceramic substratums are widely used in electronics. These substratums relocate warm away from elements efficiently. This protects against overheating. Electronic gadgets require reliable efficiency. High warm can damage circuits. AlN substrates fix this trouble. They work far better than conventional products like alumina. AlN has thermal conductivity approximately 170 W/mK. This is a lot higher than alumina’s 20 W/mK. Warmth spreads promptly via AlN. This keeps devices secure throughout operation.

LED illumination systems utilize AlN substrates. LEDs produce warm throughout use. Poor warm management shortens their life expectancy. AlN substratums help LEDs last longer. They additionally enhance brightness consistency. Power electronics count on these substrates too. Gadgets like inverters and converters deal with high power. They create significant warm. AlN substratums handle this warmth. This minimizes failure prices. It also enhances device efficiency.

The auto industry gain from AlN. Electric lorries make use of power modules and sensors. These parts need products that handle warm and electrical tension. AlN substratums are optimal. They shield electricity well. They likewise resist thermal shock. This makes them long lasting in severe conditions. Aerospace applications utilize AlN similarly. Tools in satellites or aircraft encounters extreme temperature levels. AlN makes sure steady efficiency.

AlN substrates are common in RF and microwave devices. High-frequency circuits generate warm rapidly. Effective thermal management is critical. AlN’s buildings protect against signal loss. They additionally maintain signal stability. Laser innovation uses these substrates also. High-power lasers need materials that dissipate warm quick. AlN keeps laser systems cool down. This boosts precision and dependability.

Producers pick AlN for its combination of traits. It works in high-temperature atmospheres. It withstands rust and wear. These features make it functional. Industries from telecom to medical gadgets use AlN. Its duty beforehand technology grows as devices require better warmth control.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Thermal Conductivity Aln/Aluminum Nitride Ceramic Substrate

What is Aluminum Nitride Ceramic Substrate used for? Aluminum Nitride Ceramic Substrate moves heat efficiently. It works in high-power electronics, LED lighting, and semiconductor devices. This material keeps systems cool. It stops overheating in circuits. Industries pick it for heat-sensitive applications. It handles extreme temperatures without breaking down.

Why pick Aluminum Nitride over Alumina? Aluminum Nitride moves heat better than Alumina. Alumina has lower thermal conductivity. Aluminum Nitride matches silicon’s thermal expansion. This reduces stress in electronic parts. It lasts longer under thermal cycling. Aluminum Nitride resists chemical corrosion. It works in harsh environments.

What temperatures can Aluminum Nitride handle? Aluminum Nitride works up to 2200°F in inert gas or vacuum. It stays stable below 1350°F in air. Most electronics use it below 930°F. It keeps performance steady in normal conditions. Avoid sudden temperature changes. This prevents cracks.

How to handle Aluminum Nitride substrates safely? Aluminum Nitride is brittle. Avoid dropping or hitting it. Use gloves to keep surfaces clean. Dust or oils lower performance. Clean with isopropyl alcohol. Do not expose to rapid heating or cooling. Thermal shock breaks the material. Store in dry places. Moisture causes no harm but keeps handling simple.

Can Aluminum Nitride substrates be customized? Yes. Sizes and shapes adjust to needs. Laser cutting creates precise dimensions. Surfaces polish for smooth finishes. Metallization adds copper or gold layers. This improves electrical connections. Holes or grooves are possible. Custom thickness ranges from 0.25mm to 10mm. Tell suppliers your requirements early. They optimize production steps.

(High Thermal Conductivity Aln/Aluminum Nitride Ceramic Substrate)

REQUEST A QUOTE

RELATED PRODUCTS

Manufacturing AIN Aluminum Nitride Ceramic Discs Aluminum Nitride Disk

170W/m.k High Thermal Conductivity ALN Ceramic Substrate Aluminium Nitride Sheet

220V 380V Aluminum Nitride Ceramic Sheet AlN Heating Element Heater Plates

AlN Aluminum Nitride Ceramic Plate

Premium Ceramics Product Ultrathin High Temperature Polished Aln Aluminum Nitride Ceramic Substrate Sheet