Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of aluminum nitride ceramics

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of aluminum nitride ceramics

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

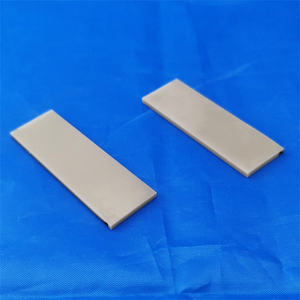

(Hot ing Alumina Nitride Sheet Substrate Wafer Aluminum Nitride Ceramic Substrate Aln Wafer)

Specifications of Hot ing Alumina Nitride Sheet Substrate Wafer Aluminum Nitride Ceramic Substrate Aln Wafer

The Hot Pushed Alumina Nitride Sheet Substrate Wafer is a high-performance ceramic product developed for advanced industrial applications. It integrates exceptional thermal conductivity with strong electrical insulation. This makes it suitable for usage in electronic devices, power components, and high-temperature environments. The product consists of light weight aluminum nitride (AlN) ceramic, produced with a hot-pressing procedure. This method makes sure high thickness and harmony in the final product.

The substratum wafer provides a thermal conductivity score of 170-200 W/m · K. This permits reliable warm dissipation, crucial for avoiding overheating in digital devices. Its coefficient of thermal expansion very closely matches products like silicon. This lowers stress and anxiety and cracking when bound to semiconductors or various other elements. The product runs reliably in temperatures up to 1400 ° C. It keeps security under quick thermal biking, ensuring long-term toughness.

Criterion thickness choices variety from 0.25 mm to 3.0 mm. Custom-made measurements are offered to satisfy specific layout requirements. Surface area surfaces include polished and rugged variants. Polished surfaces achieve roughness degrees below 0.1 µm, appropriate for precision applications. The wafer’s flexural toughness goes beyond 300 MPa, resisting mechanical damage throughout dealing with or procedure.

Electric insulation properties include a volume resistivity of over 10 ^ 14 Ω · cm. This avoids existing leak in high-voltage systems. The material’s dielectric strength goes beyond 15 kV/mm, guaranteeing safety and security in demanding electrical environments. Chemical resistance is one more crucial attribute. The substratum withstands deterioration from acids, alkalis, and molten metals, expanding its life expectancy in severe problems.

Applications include LED packaging, semiconductor manufacturing, and RF/microwave elements. It is likewise utilized in automotive power electronics and aerospace systems. The wafer sustains metallization processes like thin-film deposition or thick-film printing. This allows smooth combination into circuits or heat sinks. Custom-made shapes, openings, or patterns can be included during production.

The AlN ceramic substratum is RoHS-compliant and devoid of harmful compounds. It fulfills worldwide requirements for quality and performance.

(Hot ing Alumina Nitride Sheet Substrate Wafer Aluminum Nitride Ceramic Substrate Aln Wafer)

Applications of Hot ing Alumina Nitride Sheet Substrate Wafer Aluminum Nitride Ceramic Substrate Aln Wafer

Warm alumina nitride sheet substratum wafers (AlN wafers) are sophisticated ceramic materials with high thermal conductivity and electric insulation. These residential properties make them suitable for requiring applications in electronic devices and engineering. Electronics makers use AlN wafers as base materials for semiconductor tools. They handle high warmth created by power chips, ensuring steady performance in circuits. LED lights systems count on AlN substrates to manage warmth from high-brightness LEDs. This protects against overheating and prolongs the life expectancy of lighting modules.

Power electronic devices take advantage of AlN wafers in electrical lorries and renewable energy systems. The product’s capacity to move heat promptly enhances performance in inverters and converters. Superhigh frequency (RF) gadgets utilize AlN substrates for high-frequency signal transmission. Their reduced signal loss and thermal stability support 5G modern technology and radar systems.

Aerospace and defense markets utilize AlN ceramic substrates in sensors and control components. The material withstands extreme temperature levels and severe environments. Industrial furnace integrate AlN wafers as burner or insulators. Their thermal shock resistance enables fast temperature level modifications without damages.

Medical tools suppliers use AlN substratums in imaging gadgets and laser systems. The ceramic’s electrical insulation protects against interference with sensitive parts. AlN wafers are compatible with thin-film deposition procedures. This makes them ideal for producing accurate circuits in microelectronics.

Automotive electronic devices make use of AlN substratums for engine control units and battery administration. The product’s resilience guarantees integrity under resonance and temperature variations. Optoelectronic devices integrate AlN wafers to sustain laser diodes and optical sensors. Their thermal management capacities maintain precision in light-based systems.

AlN ceramic substratums are changing standard products like alumina in high-performance applications. Their superior warmth dissipation reduces the demand for bulky air conditioning systems. Manufacturers value AlN wafers for their chemical inertness and mechanical strength. These features enable lasting usage in destructive or high-wear settings. Research continues to expand AlN applications in emerging modern technologies like quantum computer and advanced sensing units.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Hot ing Alumina Nitride Sheet Substrate Wafer Aluminum Nitride Ceramic Substrate Aln Wafer

What is an Aluminum Nitride Ceramic Substrate? An Aluminum Nitride (AlN) ceramic substrate is a material made from aluminum and nitrogen. It moves heat well and stops electricity from passing through. People use it in electronics where controlling heat matters. It works better than many other ceramics in high-power situations.

Why pick Aluminum Nitride over other materials? Aluminum Nitride moves heat faster than most ceramics. It expands at a rate close to silicon, which helps in electronics. It also insulates electricity better than materials like alumina. These traits make it last longer in tough conditions.

Where is Aluminum Nitride used? It’s common in LED lighting, power electronics, and semiconductor devices. It handles high heat in laser systems or radio-frequency equipment. Factories use it for circuits needing heat spread quickly. Cars, aerospace, and telecom industries rely on it for reliable parts.

How is handling Aluminum Nitride different? AlN is less fragile than alumina but still needs care. Avoid dropping it or hitting it hard. Clean it with dry tools to prevent cracks. It resists chemicals better than some ceramics, but harsh acids or bases can damage it.

Can Aluminum Nitride substrates be customized? Yes. Makers cut AlN into shapes like circles, squares, or rectangles. Thickness ranges from under 0.5mm to several millimeters. Holes, coatings, or metal layers can be added. Share size and use details with suppliers for exact needs.

(Hot ing Alumina Nitride Sheet Substrate Wafer Aluminum Nitride Ceramic Substrate Aln Wafer)

REQUEST A QUOTE

RELATED PRODUCTS

High Thermal Conductivity AlN Aluminum Nitride Ceramic Sheet

Wear Resistance Insulation ALN Aluminum Nitride Ceramic Ring/ Spacer/Insulator

SINTYRON Semiconductor Ceramic Single Crystal 170 180w High Thermal Conductivity Aln Aluminum Nitride Ceramic Substrate

CNC Machinable Insulated AlN Aluminum Nitride Ceramic Tube

Double Sided Polished Aluminium Nitride Ceramic Plate ALN Sheet For LED