Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of aluminum nitride ceramics

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of aluminum nitride ceramics

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

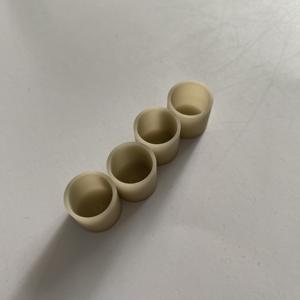

(Industry Electrical CNC Machining Ceramic Parts Aluminum Nitride Ceramic ALN Heat Sink for CPU LED)

Specifications of Industry Electrical CNC Machining Ceramic Parts Aluminum Nitride Ceramic ALN Heat Sink for CPU LED

This item is made for high-performance thermal management in electronic devices. It makes use of light weight aluminum nitride ceramic (ALN) material. The product uses excellent thermal conductivity. It rises to 170-200 W/m · K. This makes certain rapid warmth transfer far from sensitive parts like CPUs and LEDs. The ALN ceramic parts are produced utilizing sophisticated CNC machining. This guarantees precise dimensional accuracy. Tolerances are managed within ± 0.02 mm. The surface area finish can be personalized between Ra 0.1 μm to Ra 0.4 μm. This fulfills strict needs for smooth user interfaces with digital tools.

Light weight aluminum nitride ceramic is electrically shielding. Its resistivity surpasses 10 ^ 14 Ω · cm. This stops current leakage in high-voltage applications. The product’s thermal development coefficient matches silicon. This minimizes stress and anxiety at bonding user interfaces. It boosts long-term integrity in semiconductor settings. The parts operate effectively in temperature levels from -50 ° C to 600 ° C. They withstand thermal shock and chemical deterioration. This makes them ideal for rough industrial conditions.

The warm sinks are compatible with common installing methods. They include screw attachment, adhesive bonding, and clamping. Custom-made shapes and sizes are readily available. Common measurements vary from 10 mm x 10 mm to 200 mm x 200 mm. Density ranges 1 mm and 20 mm. Openings, channels, and grooves can be added for maximized air flow or fluid air conditioning.

Applications include power electronics, LED lights systems, and high-frequency RF gadgets. They are made use of in auto control components, telecommunications base terminals, and renewable resource inverters. The ALN ceramic parts change conventional aluminum or copper warmth sinks. They give much better efficiency in small, high-power layouts.

Quality assurance complies with ISO 9001 criteria. Each batch undertakes rigorous screening. Tests include thermal conductivity confirmation, dimensional inspection, and surface area defect analysis. X-ray scanning discovers internal cracks or spaces. The product is packaged in anti-static foam. Delivering options consist of vacuum-sealed bags for moisture-sensitive settings.

Technical assistance is readily available for style optimization. Personalized orders require a 3D CAD documents. Lead times vary from 2 to 6 weeks based upon complexity. Bulk prices discounts obtain orders above 500 systems. Examples are offered performance recognition prior to major production.

(Industry Electrical CNC Machining Ceramic Parts Aluminum Nitride Ceramic ALN Heat Sink for CPU LED)

Applications of Industry Electrical CNC Machining Ceramic Parts Aluminum Nitride Ceramic ALN Heat Sink for CPU LED

Light Weight Aluminum Nitride (ALN) ceramic heat sinks are critical elements in modern-day electronics. These components take care of high warmth effectively. They are made using CNC machining. This procedure ensures accuracy. ALN ceramic has exceptional thermal conductivity. It moves warm far from delicate parts promptly. This maintains devices stable. It functions better than steels like light weight aluminum in a lot of cases. ALN resists electric currents. This stops brief circuits. It suits high-power applications.

Industries use ALN heat sinks for CPUs. Processors create substantial warm throughout procedure. Overheating lowers efficiency. ALN ceramic warmth sinks soak up and distribute this heat. This maintains CPU efficiency. It expands gadget lifespan. LED systems also rely upon ALN components. High-brightness LEDs create intense heat. Efficient thermal management is important. ALN heat sinks avoid getting too hot. This guarantees consistent light output. It stays clear of color changes or failure.

CNC machining shapes ALN ceramic accurately. The approach allows complex designs. Limited resistances are possible. This matches exact needs of digital devices. CNC machining prevents splits or problems. It creates smooth surface areas. This improves call with warm sources. ALN ceramic is hard. Traditional methods battle to device it. CNC tools handle it dependably.

The material operates in harsh settings. ALN withstands chemical corrosion. It holds up against severe temperature levels. This suits commercial machinery. Electric insulation remains intact under stress and anxiety. ALN heat sinks are long lasting. They need minimal maintenance.

Need grows in aerospace and automobile fields. These fields require light-weight, efficient options. ALN ceramic meets these requirements. It minimizes system weight. This boosts gas efficiency. Electric vehicles take advantage of ALN thermal management. Battery systems stay cooler. Efficiency enhances.

Producers focus on CNC machining for ALN parts. The method guarantees consistency. High-volume manufacturing stays cost-efficient. Custom-made layouts are possible. This flexibility supports innovation. Engineers incorporate ALN warm sinks into sophisticated electronics. Reliability rises. Downtime reduces.

ALN ceramic warm sinks are essential for modern-day innovation. Their role in thermal administration is unequaled. CNC machining allows their precise manufacturing. Industries depend on these parts for optimum performance.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Industry Electrical CNC Machining Ceramic Parts Aluminum Nitride Ceramic ALN Heat Sink for CPU LED

What makes Aluminum Nitride Ceramic heat sinks suitable for CPU and LED applications? Aluminum Nitride (ALN) has high thermal conductivity. It moves heat away from sensitive components efficiently. The material insulates electrically. This prevents short circuits. It resists corrosion and handles extreme temperatures. These traits make ALN ideal for high-performance electronics.

Why choose CNC machining for ALN ceramic parts? CNC machining creates precise shapes. It meets tight tolerances needed for heat sinks. The process allows complex designs. Custom patterns improve heat dissipation. Machined surfaces stay smooth. Smooth surfaces ensure better contact with heat sources. CNC works well for small batches or mass production.

Where are ALN ceramic heat sinks commonly used? They cool CPUs in computers and servers. LEDs use them to manage heat in lighting systems. Power electronics like inverters rely on ALN for thermal control. Industries like aerospace and automotive use these parts. High-frequency devices benefit from ALN’s stable performance.

How does ALN compare to alumina or aluminum heat sinks? ALN conducts heat better than alumina. It transfers heat faster than aluminum in some cases. ALN insulates electricity. Aluminum conducts electricity. ALN matches silicon’s thermal expansion. This reduces stress in electronic assemblies. ALN costs more. It suits applications needing top performance.

What precautions are needed when handling ALN heat sinks? Avoid mechanical shock during installation. ALN is hard but brittle. Use proper tools to prevent cracks. Clean surfaces before mounting. Ensure even pressure when attaching to components. Thermal paste improves contact. Follow manufacturer guidelines for torque settings. Store parts in dry conditions to avoid contamination.

(Industry Electrical CNC Machining Ceramic Parts Aluminum Nitride Ceramic ALN Heat Sink for CPU LED)

REQUEST A QUOTE

RELATED PRODUCTS

MAX Special Ceramics Material Titanium Aluminum Nitride Ti4AlN3 Powder

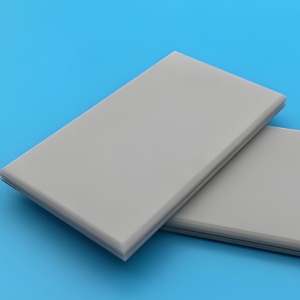

AlN Aluminium Nitride Ceramic Sheets / Substrate/plate for Semiconductor

180W/mk High Thermal Conductivity Aluminum Nitride Ceramic Pad AIN ALN Ceramic Sheet for IC MOS Tube/IGBT Chip

Aln Ceramics Aluminum Nitride Ceramic for Microwave Equipment Packaging

Electrical Insulation AlN Aluminium Nitride Ceramic Plate