Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

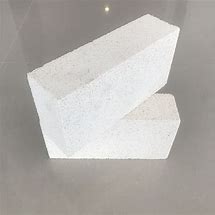

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(99% Alumina Ceramic Plate for Semiconductor/Medical/Electronics, High Purity, Wear Resistant, Insulating)

Specifications of 99% Alumina Ceramic Plate for Semiconductor/Medical/Electronics, High Purity, Wear Resistant, Insulating

This 99% alumina ceramic plate serves semiconductor, clinical, and electronic devices industries. It gives high efficiency sought after environments. The product has 99% aluminum oxide, ensuring marginal impurities. High pureness sustains applications requiring chemical security and contamination control. Its thick structure stands up to wear, expanding life span in unpleasant conditions. The plate preserves strength under high temperatures, operating reliably up to 1600 ° C. Thermal shock resistance avoids breaking during quick temperature level shifts. Electric insulation homes avoid current leakage, suitable for electronic parts. The dielectric toughness goes beyond 15 kV/mm, meeting strict security requirements. Surface smoothness lowers friction, appropriate for precision equipment. Adjustable measurements include thicknesses from 0.5 mm to 50mm. Resistances remain within ± 1% for crucial design needs. The material stands up to acids, alkalis, and natural solvents. Corrosion resistance makes sure sturdiness in severe chemical processes. Biocompatibility makes it safe for medical devices and implants. Reduced particle generation matches cleanroom environments. Machining choices consist of laser cutting, grinding, and polishing. Pre-drilled holes or particular surface area appearances are readily available. Home plate meets RoHS and ISO 9001 standards for quality control. It changes metals in applications needing electric isolation. High firmness (Hv 1500) reduces scrapes and surface damages. Thermal conductivity stays reduced, avoiding warm transfer to delicate components. Applications include wafer handling components, insulating substrates, and surgical gadget parts. It works as a vacuum chamber lining in semiconductor manufacturing. Medical usages include sterilization trays and imaging equipment components. Electronics integration consists of circuit providers and high-voltage insulators. Custom branding or component numbers can be added. Checking records verify pureness, thickness, and mechanical residential or commercial properties. Mass orders ship with safety packaging to stop chipping. Technical support assists with material selection and layout requirements.

(99% Alumina Ceramic Plate for Semiconductor/Medical/Electronics, High Purity, Wear Resistant, Insulating)

Applications of 99% Alumina Ceramic Plate for Semiconductor/Medical/Electronics, High Purity, Wear Resistant, Insulating

99% alumina ceramic plates are advanced materials with high performance sought after industries. Their high purity and exceptional physical residential properties make them perfect for semiconductor, medical, and electronics applications. These plates are made from 99% light weight aluminum oxide, guaranteeing minimal pollutants. This is critical for environments where contamination threats have to be eliminated.

In semiconductor manufacturing, alumina ceramic plates manage extreme problems. They work as protecting components in high-temperature procedures. Their wear resistance enables repeated usage without destruction. The product’s electrical insulation avoids interference with sensitive circuits. This dependability sustains the production of integrated circuits and digital tools.

Clinical applications benefit from the biocompatibility of alumina ceramics. They are utilized in surgical devices, implants, and diagnostic devices. High pureness makes sure safety and security for contact with human tissue. The plates withstand corrosion from decontaminating agents. Their hardness minimizes wear in precision instruments. This prolongs the life expectancy of medical tools.

Electronics count on alumina plates for insulation and thermal monitoring. They are used in motherboard, sensing units, and high-voltage systems. The product dissipates warmth successfully, safeguarding elements from overheating. Its electric insulation stops short circuits. Alumina’s longevity guarantees security in rough operating conditions. This is crucial for commercial electronics and interaction systems.

The wear-resistant nature of alumina ceramic plates lowers maintenance expenses. They hold up against abrasion in mechanical systems. Their firmness outshines lots of steels and polymers. This makes them ideal for high-friction applications. The material maintains its buildings under anxiety.

High-purity alumina porcelains are chemically inert. They resist acids and antacids in aggressive atmospheres. This security is important for laboratory equipment and chemical handling. Home plates preserve honesty even when subjected to reactive compounds.

These plates incorporate performance with expense efficiency. Their long life span reduces substitute frequency. Industries prioritize them for important applications. The adaptability of alumina porcelains meets diverse technical requirements. Their duty in advancing technology and health care remains to grow.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 99% Alumina Ceramic Plate for Semiconductor/Medical/Electronics, High Purity, Wear Resistant, Insulating

What is 99% alumina ceramic plate?

99% alumina ceramic plate is a high-performance material made mostly from aluminum oxide. It is designed for demanding industries like semiconductors, medical devices, and electronics. The high alumina content ensures strength, heat resistance, and electrical insulation. It works well in harsh environments where other materials fail.

Why is high purity important for this ceramic plate?

High purity (99% alumina) minimizes contaminants that could harm sensitive processes. In semiconductors, impurities disrupt electrical performance. In medical applications, purity prevents reactions with bodily tissues or chemicals. Electronics rely on pure materials for stable insulation and signal integrity. Even tiny impurities cause big problems.

How does wear resistance benefit industrial use?

Alumina ceramic plates resist abrasion, friction, and erosion. Semiconductor manufacturing involves moving parts and chemicals that wear down equipment. Medical tools face repeated sterilization and mechanical stress. Electronics production uses abrasive polishing steps. The plate’s hardness extends product life, cuts downtime, and lowers replacement costs.

What makes this material electrically insulating?

Aluminum oxide naturally blocks electric current. The 99% alumina structure has no free electrons to conduct electricity. This insulation prevents short circuits in high-voltage semiconductor equipment. It protects medical devices from interference. Electronics stay safe from leakage currents or overheating. Performance stays consistent even at high temperatures.

Where is this ceramic plate commonly applied?

Semiconductor factories use it for wafer processing parts, heaters, and insulators. Medical devices include surgical tools, implants, and imaging equipment components. Electronics manufacturers apply it in circuit substrates, sensors, and high-frequency insulation. Labs use it for corrosive chemical handling. Any industry needing durability, insulation, and reliability uses this material.

(99% Alumina Ceramic Plate for Semiconductor/Medical/Electronics, High Purity, Wear Resistant, Insulating)

REQUEST A QUOTE

RELATED PRODUCTS

High Alumina Ceramic Heater Rod Porcelain Components 95

Precision Ceramic Tubes High Temperature Resistant High Hardness 99% Alumina Ceramic Parts

Al2O3 Ceramic Hot Selling Refractory Alumina Brick Kiln Rotary Kiln Building Making Clay Brick For Oven

96 Alumina Ceramic Substrate

Industrial High Purity High Temperature Resistance 99% Alumina Ceramic Structural Component