Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

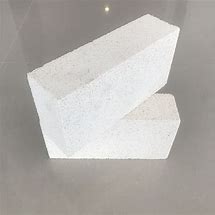

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Al2o3 Crucible Alumina Ceramic High Refractoriness Alumina Al2O3 Ceramic Crucible)

Specifications of Al2o3 Crucible Alumina Ceramic High Refractoriness Alumina Al2O3 Ceramic Crucible

The Al2O3 Crucible Alumina Porcelain High Refractoriness Alumina Porcelain Crucible is created for high-temperature applications. It is made from high-purity light weight aluminum oxide (Al2O3) with an alumina content commonly above 99%. This makes sure superb thermal security and resistance to severe warm. The crucible runs properly in temperature levels as much as 1800 ° C. It preserves architectural integrity under prolonged exposure to extreme warmth.

The product’s reduced thermal development coefficient decreases splitting risks during rapid temperature changes. This makes it appropriate for duplicated home heating and cooling down cycles. The crucible withstands thermal shock better than lots of typical products. It performs well in settings with unexpected temperature level changes.

Chemical stability is a vital attribute. The Al2O3 crucible resists rust from acids, alkalis, and molten steels. It is perfect for use in chemical laboratories and metal melting procedures. The non-reactive surface prevents contamination of samples or melts. This guarantees constant cause delicate applications.

Mechanical stamina is high as a result of the thick ceramic framework. The crucible manages hefty lots without contortion. It is resilient under mechanical stress and anxiety. This prolongs its life span even popular commercial settings.

The product is available in several shapes and sizes. Customized measurements can be generated to meet details needs. Common styles consist of cylindrical, conical, and rectangle-shaped types. Surface area surfaces are smooth to decrease deposit adherence. This simplifies cleansing and upkeep.

Applications consist of metallurgy, glass production, and semiconductor manufacturing. It is used for melting, calcining, and evaluating high-purity products. The crucible works with electrical heating systems, induction heating systems, and gas-fired arrangements.

Production uses advanced sintering strategies. This ensures uniform thickness and marginal problems. Each batch undergoes stringent top quality checks. Specifications like porosity and thermal conductivity are regulated for ideal performance.

Modification choices consist of adding takes care of, covers, or unique finishings. These alterations boost capability for specialized procedures. The crucible is packaged securely to prevent damage during delivery. It arrives prepared for prompt use in high-temperature procedures.

(Al2o3 Crucible Alumina Ceramic High Refractoriness Alumina Al2O3 Ceramic Crucible)

Applications of Al2o3 Crucible Alumina Ceramic High Refractoriness Alumina Al2O3 Ceramic Crucible

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Al2o3 Crucible Alumina Ceramic High Refractoriness Alumina Al2O3 Ceramic Crucible

What is an Al2O3 ceramic crucible? An Al2O3 ceramic crucible is a container made from alumina ceramic material. It is designed for high-temperature applications like melting metals or conducting lab experiments. The main component is aluminum oxide (Al2O3), which gives the crucible strong heat resistance. Alumina content typically ranges above 99%, ensuring stability in extreme conditions. This material resists chemical corrosion and thermal shock effectively.

What maximum temperature can it withstand? Al2O3 crucibles handle temperatures up to 1800°C. They remain stable even under rapid heating or cooling cycles. This makes them suitable for industrial furnaces or precision lab work. The high refractoriness prevents deformation or cracking. Proper use ensures long-term performance without degradation.

What are the advantages over other crucibles? Alumina crucibles outperform materials like graphite or quartz. They resist chemical reactions with acids, alkalis, and molten metals. High purity reduces contamination risks in sensitive processes. Their mechanical strength lasts longer under repeated use. Lower replacement frequency makes them cost-effective over time.

What precautions are needed during use? Avoid sudden impacts or drops to prevent cracks. Do not expose hot crucibles to cold liquids directly. Thermal shock weakens the structure. Use tongs or protective gear when handling heated crucibles. Inspect for damage before each use. Store in dry conditions to maintain integrity.

How to select the right Al2O3 crucible? Check the alumina content for your temperature needs. Higher alumina grades suit extreme heat. Match the crucible size and shape to your equipment. Thicker walls improve durability for abrasive materials. Verify compatibility with the substances being melted. Custom designs are available for specialized applications.

(Al2o3 Crucible Alumina Ceramic High Refractoriness Alumina Al2O3 Ceramic Crucible)

REQUEST A QUOTE

RELATED PRODUCTS

Custom Alumina Ceramic Al2o3 Boats

Alumina Ceramics Whole High Quality Industrial Ceramic Textile Ceramic Eco-friendly Winner Textile Knitting

Ceramic C795 95% Alumina Ceramic Top Smoking Rolling Smoking Accessories

Al2O3 Ceramic Hot Selling Refractory Alumina Brick Kiln Rotary Kiln Building Making Clay Brick For Oven

High Temperature Chemical Industrial 92 95 Al2o3 High Alumina Ceramic Plate