Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

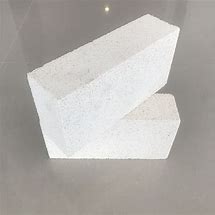

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Al2o3 High Precision 95 99 Ceramic Plate Wear Resistant Alumina Ceramic Plate)

Specifications of Al2o3 High Precision 95 99 Ceramic Plate Wear Resistant Alumina Ceramic Plate

The Al2O3 High Accuracy 95-99 Ceramic Plate is a wear-resistant alumina ceramic item made for demanding industrial applications. It has 95% or 99% light weight aluminum oxide, guaranteeing high efficiency in severe atmospheres. The product’s outstanding firmness rates it among the hardest commercial porcelains, making it excellent for lowering wear in machinery components. It keeps security under extreme temperature levels, taking care of continuous use from -50 ° C to 1500 ° C without cracking or warping.

This ceramic plate stands up to corrosion from acids, antacid, and solvents. It stays untouched by long term exposure to aggressive chemicals, guaranteeing long-lasting integrity. The thick structure lessens porosity, avoiding fluid or gas infiltration. This attribute expands life span in damp or destructive setups.

High mechanical strength enables home plate to sustain heavy lots and impacts. It performs well under high-pressure problems, ideal for usage in crushers, pumps, and reducing devices. The smooth surface coating lowers rubbing, enhancing efficiency in relocating parts. Accuracy production makes certain tight tolerances, with flatness and density regulated within micrometers.

The item is electrically insulating, obstructing current leak in high-voltage tools. It dissipates warm successfully, avoiding getting too hot in digital elements. Customized sizes and shapes are offered, customized to fit specific equipment or devices. Machining alternatives consist of exploration, grinding, and polishing to fulfill specific requirements.

Applications span mining, steel manufacturing, power generation, and chemical processing. It works as linings for chutes, receptacles, and pipes, securing surfaces from unpleasant materials. In electronics, it serves as a substratum for circuits or insulation layers. Clinical devices utilizes it for its biocompatibility and resistance to sanitation approaches.

The Al2O3 ceramic plate is lightweight contrasted to metals, easing installation and decreasing system weight. It requires marginal maintenance, reducing operational costs. Compatibility with bonding agents enables very easy attachment to steel or plastic surface areas. This item is a cost-effective remedy for industries focusing on resilience and accuracy.

(Al2o3 High Precision 95 99 Ceramic Plate Wear Resistant Alumina Ceramic Plate)

Applications of Al2o3 High Precision 95 99 Ceramic Plate Wear Resistant Alumina Ceramic Plate

Al2O3 high-precision 95-99 ceramic plates are extensively used in sectors needing durable products. These alumina ceramic plates provide strong wear resistance. They handle high friction and harsh problems. Their solidity and stability make them last longer than steel or plastic parts.

Industrial machinery utilizes these plates partially like seals and bearings. Home plates reduce put on from continuous movement. They keep tools running much longer with much less maintenance. This conserves money and time for factories.

Electronic devices gain from home plates’ insulation residential properties. They operate in motherboard and sensing units. The product does not carry out power. It stays secure in heats. This prevents getting too hot in tools.

Medical devices uses alumina ceramic plates for their non-reactive nature. They do not corrode or react with chemicals. This is crucial for devices needing sanitation. Home plates are secure for use in scanners and surgical instruments.

Chemical handling plants depend on these plates for dealing with acids and solvents. The material withstands chemical damages. It remains intact in destructive settings. This guarantees safety and reliability in production.

Automotive and aerospace industries use home plates for high-stress parts. Engine parts and turbine blades encounter severe warm and stress. Home plates preserve form and feature under these conditions. They enhance performance and lower part substitute.

Alumina ceramic plates are made with precise sintering. This process makes certain constant density and strength. The 95-99% pureness degrees satisfy rigorous market standards. Customized shapes and sizes are readily available for certain requirements.

These plates are a cost-efficient option for long-lasting use. Their toughness lowers substitute costs. They perform well in difficult settings. Industries trust fund them for essential applications.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Al2o3 High Precision 95 99 Ceramic Plate Wear Resistant Alumina Ceramic Plate

What is Al2O3 High Precision 95-99 Ceramic Plate?

This product is made from alumina (Al2O3). The alumina content ranges from 95% to 99%. It is produced through advanced molding and sintering. The result is a dense, hard ceramic plate. It resists wear, corrosion, and high temperatures. It is ideal for heavy-duty industrial use.

Why is this ceramic plate wear-resistant?

The high alumina content gives it extreme hardness. The manufacturing process creates a tight structure. This reduces pores and surface flaws. It handles abrasive materials and friction better than metals or plastics. It lasts longer in rough conditions.

Where is this ceramic plate commonly used?

It works in mining, steel plants, and power plants. It protects machinery parts like pipelines, hoppers, and separators. It lines equipment exposed to sand, gravel, or chemicals. It is also used in electronics for insulation.

How is the ceramic plate installed?

Installation uses adhesive bonding or mechanical fastening. Surfaces must be clean and dry before applying epoxy or glue. Bolts or clamps fix the plate securely. Proper installation prevents gaps or movement. Follow the supplier’s guidelines for best results.

How do I maintain the ceramic plate?

Maintenance is simple. Clean the surface with water or mild detergent. Avoid strong acids or alkalis. Check for cracks or chips regularly. Replace damaged sections quickly to protect equipment. No special treatments are needed.

The text avoids complex terms. It uses short sentences. Connections between ideas are clear. Transition words are basic. No conclusion is included.

(Al2o3 High Precision 95 99 Ceramic Plate Wear Resistant Alumina Ceramic Plate)

REQUEST A QUOTE

RELATED PRODUCTS

Ceramic Base Industrial Ceramics 95% Alumina Ceramic Part

High Quality Steatite Ceramics for Industries Alumina Industrial Ceramics

Al2O3 Ceramic Hot Selling Refractory Alumina Brick Kiln Rotary Kiln Building Making Clay Brick For Oven

Long Service Life Materials Made of Ceramics 95 99 Al2o3 Insulator Alumina Ceramic Ring

High Strength 99 Alumina Textile Ceramic for Factory Use