Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

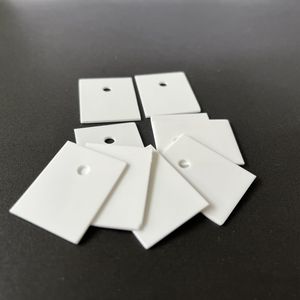

(Customizable Alumina 99 Porcelain Ceramic Tube Insulated Al2O3 Ceramic Tubes Moulded Ceramic Plates)

Specifications of Customizable Alumina 99 Porcelain Ceramic Tube Insulated Al2O3 Ceramic Tubes Moulded Ceramic Plates

Personalized Alumina 99 Porcelain Ceramic Tubes and Moulded Porcelain Plates are developed for industrial applications needing high performance. These items are made from 99% pure aluminum oxide (Al2O3). This product guarantees exceptional thermal stability, electrical insulation, and resistance to harsh chemicals. The ceramic tubes manage temperatures as much as 1700 ° C. They maintain structural honesty under severe heat. The moulded plates supply comparable buildings with level or customized shapes. Both items resist corrosion from acids, antacid, and molten metals. This makes them ideal for hostile atmospheres.

The ceramic tubes come in numerous sizes, sizes, and wall thicknesses. Custom-made dimensions are available to satisfy details demands. The surface area finish can be adjusted for level of smoothness or structure. This boosts efficiency in applications like electrical insulation or thermal management. The moulded plates are precision-engineered for constant thickness and monotony. They can include openings, slots, or facility geometries. This enables assimilation right into existing machinery or systems.

These alumina ceramics are suitable for industries such as metallurgy, semiconductors, and energy. They function successfully in heating system linings, kiln furniture, and laboratory equipment. Televisions are used in thermocouple protection, heating elements, and sensing unit real estates. The plates act as insulators, wear-resistant surfaces, or substrates for digital parts. Their high dielectric toughness protects against electrical leak. This guarantees safety in high-voltage applications.

Longevity is a crucial advantage. The alumina structure resists mechanical tension and thermal shock. This reduces breaking or deformation over time. The material’s hardness decreases wear from abrasion or rubbing. Maintenance needs are reduced. This lowers long-lasting expenses.

Personalization alternatives consist of branding, labeling, or specific packaging. Technical assistance is attended to design adjustments. Examples can be tested prior to full-scale manufacturing. Lead times differ based upon order size and complexity. Mass orders obtain reduced pricing.

The items follow global standards for ceramic products. Quality assurance checks guarantee uniformity in thickness, purity, and measurements. Accreditations are readily available upon request. Eco-friendly production processes reduce waste. Recyclable materials are used where possible.

These ceramic services attend to challenges in high-temperature, destructive, or electrically delicate setups. They improve functional performance and tools life expectancy. Performance is trusted under constant use. Compatibility with various other industrial products is made certain. International shipping alternatives are available. Customer service helps with technical inquiries or order monitoring.

(Customizable Alumina 99 Porcelain Ceramic Tube Insulated Al2O3 Ceramic Tubes Moulded Ceramic Plates)

Applications of Customizable Alumina 99 Porcelain Ceramic Tube Insulated Al2O3 Ceramic Tubes Moulded Ceramic Plates

Adjustable alumina 99 porcelain ceramic tubes and formed ceramic plates are commonly utilized in industrial and technological areas. These items are made from high-purity Al2O3 ceramic. They handle extreme conditions. The product stands up to heats. It stays stable as much as 1600 ° C. This makes it perfect for heater linings or thermocouple security tubes. Factories use these parts in steel processing. They avoid warm damages to devices.

The electric insulation residential properties are strong. Alumina ceramic tubes shield cables in high-voltage systems. They stop electrical leakages. Electronic devices makers depend on them for circuit parts. Televisions shield delicate components from heat or sparks. This enhances device safety.

Chemical labs make use of these ceramics too. They resist acids and antacids. Activators or piping systems made from Al2O3 ceramic last much longer. They stay clear of deterioration. This cuts maintenance costs. The smooth surface quits material accumulation. It maintains processes effective.

Custom-made forms are feasible. Makers mold ceramic plates into particular styles. These plates function as substratums in electronics. They hold silicon chips or sensing units. The material dissipates warmth well. It stops overheating in gadgets.

Medical equipment utilizes alumina ceramic tubes. They are safe and biocompatible. Makers for sterilization or imaging require sturdy parts. These tubes meet rigorous hygiene criteria.

Aerospace applications exist. Engine parts face high stress. Alumina ceramic parts reduce weight. They take care of vibration and warm. This boosts fuel performance.

The hardness of Al2O3 ceramic prevents wear. Industrial machinery makes use of ceramic plates as linings. They secure surfaces from abrasion. Mining devices lasts longer with these additions.

Adjustable dimensions fit unique requirements. Thin-walled tubes match precision tools. Thick plates take care of heavy tons. Providers work with clients to change dimensions.

These porcelains work in power markets. Solar panels or batteries use them as insulators. They manage heat in power systems. This supports renewable resource projects.

Alumina 99 ceramic products address issues across sectors. Their adaptability and dependability make them essential for advanced design.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customizable Alumina 99 Porcelain Ceramic Tube Insulated Al2O3 Ceramic Tubes Moulded Ceramic Plates

What is Alumina 99 Porcelain Ceramic Tube made of?

Alumina 99 Porcelain Ceramic Tube contains 99% aluminum oxide (Al2O3). This high purity makes it strong. It resheat heat well. It handles extreme temperatures. It stays stable in harsh conditions.

How hot can these ceramic tubes get without damage?

These tubes work in temperatures up to 1700°C. They keep their shape. They resist thermal shock. Sudden temperature changes cause less cracking. They last longer in high-heat setups.

Can the shape and size be customized?

Yes. Sizes and shapes are adjustable. Tubes come in different lengths, diameters, and thicknesses. Holes or grooves are added if needed. Custom designs fit specific industrial uses.

What makes Alumina 99 better than regular ceramics?

Alumina 99 has higher purity. This improves strength. It wears down slower. It insulates electricity better. It resists chemicals. Regular ceramics lack these traits.

Where are these ceramic tubes commonly used?

They suit furnaces, kilns, and lab equipment. They protect sensors in high-temperature machines. Electronics use them for insulation. Industrial heaters rely on their heat resistance.

(Customizable Alumina 99 Porcelain Ceramic Tube Insulated Al2O3 Ceramic Tubes Moulded Ceramic Plates)

REQUEST A QUOTE

RELATED PRODUCTS

Factory Customized High Precision 95% Alumina Ceramic Parts Structural Member

99 Ceramic Machining Parts 95 96 99 99.8 Al2O3 Alumina Ceramic

Customization Industrial Insulation High Precision High Purity Ceramics 95% 99% 99.5% Structural Parts Alumina Ceramic

Ceramic C795 95% Alumina Ceramic Top Smoking Rolling Smoking Accessories

Wear Resistant Alumina Ceramic Hexagonal Tile 12mm