Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

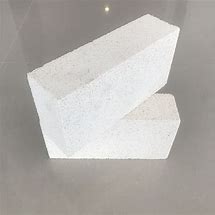

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

( Customized OEM 95% 99% 99.5% Al2O3 Alumina Ceramic Insulator Components Parts)

Specifications of Customized OEM 95% 99% 99.5% Al2O3 Alumina Ceramic Insulator Components Parts

Custom-made OEM 95% 99% 99.5% Al2O3 alumina ceramic insulator elements are engineered for high-performance industrial applications. These components make use of high-purity light weight aluminum oxide (Al2O3) to guarantee dependability popular settings. The material structure consists of three grades: 95%, 99%, and 99.5% alumina content. Greater pureness levels improve mechanical toughness, thermal stability, and electric insulation.

Alumina ceramic insulators excel in extreme problems. They resist temperatures up to 1700 ° C. They preserve stability under thermal shock. Their low thermal development minimizes splitting. The product’s solidity (Hv 15-18 Grade point average) makes certain wear resistance. Chemical inertness prevents deterioration from acids, alkalis, and solvents.

Electrical properties make these insulators ideal for high-voltage systems. The dielectric toughness exceeds 15 kV/mm. Quantity resistivity stays over 10 ^ 14 Ω · cm also at elevated temperature levels. This protects against present leakage. Applications consist of power transmission, semiconductor devices, and digital devices.

Customization options cover diverse requirements. Parts are available in tubes, rods, plates, discs, and intricate geometries. Accuracy machining guarantees limited tolerances ( ± 0.1 mm or far better). Surface area surfaces range from as-fired to brightened. Threads, grooves, and openings can be included per style specifications.

Production utilizes sophisticated processes. Dry pressing and isostatic pressing develop consistent density. Shot molding produces complex forms. Sintering at 1600-1800 ° C achieves full densification. Post-processing includes grinding, splashing, or layer.

Quality control warranties consistency. Each set undertakes thickness tests (≥ 3.7 g/cm six for 99% quality). X-ray fluorescence (XRF) confirms chemical purity. Mechanical tests examine flexural stamina (≥ 300 MPa for 99.5% grade). Electrical examinations validate insulation efficiency.

These elements offer sectors such as energy, aerospace, automobile, and clinical. Common usages consist of heating system linings, sensor real estates, laser parts, and shielding substratums. They replace steels or plastics where heat, wear, or electrical threats exist.

Custom OEM solutions adjust to certain needs. Product qualities are picked based upon operating problems. Technical support covers style optimization. Prototyping ensures fit and feature. Bulk production fulfills distribution timelines.

The product suits engineers needing long lasting, non-conductive components. It decreases downtime in high-temperature or destructive setups. Performance consistency aligns with commercial requirements. Customization makes sure compatibility with existing systems.

( Customized OEM 95% 99% 99.5% Al2O3 Alumina Ceramic Insulator Components Parts)

Applications of Customized OEM 95% 99% 99.5% Al2O3 Alumina Ceramic Insulator Components Parts

Personalized OEM 95% 99% 99.5% Al2O3 alumina ceramic insulator elements are widely used across industries. These parts supply high electric resistance, thermal security, and corrosion resistance. They perform well in severe atmospheres. The material’s pureness degree identifies its buildings. Higher alumina content improves performance.

In electronics, these insulators are crucial. They serve in circuit card, sensing units, and high-voltage equipment. The 95% quality is cost-effective for typical applications. The 99% and 99.5% qualities deal with sophisticated electronic devices requiring precision. They stop electrical leak and make certain device security.

The vehicle market utilizes alumina porcelains in ignition system, sensing units, and battery systems. High thermal security protects parts from engine heat. Electric automobiles count on these insulators for battery insulation. They lower short-circuit threats in high-temperature problems.

Energy markets depend upon alumina components for power transmission. They are utilized in insulators for high-voltage line, transformers, and renewable resource systems. The 99.5% grade matches high-voltage applications. It resists electric tracking and weathering.

Medical devices call for biocompatible products. Alumina porcelains are utilized in imaging tools and medical devices. Their non-reactive nature guarantees security in sterile settings. Custom-made shapes fulfill particular clinical device designs.

Aerospace applications demand materials that hold up against extreme anxiety. Alumina insulators are utilized in avionics, satellite systems, and engine sensing units. They resist radiation and thermal shock. High-purity grades make sure reliability in crucial systems.

Industrial machinery utilizes these elements for wear-resistant parts. They are applied in pumps, shutoffs, and cutting devices. The firmness of alumina expands equipment life expectancy. Custom shapes and sizes fit unique equipment demands.

Manufacturers tailor alumina ceramic parts to OEM specifications. Alternatives include readjusting dimensions, surface area coatings, and resistance degrees. This customization makes certain compatibility with diverse applications.

The flexibility of alumina porcelains makes them vital in modern-day technology. Various pureness levels deal with differing performance demands. Industries gain from their longevity and versatility.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customized OEM 95% 99% 99.5% Al2O3 Alumina Ceramic Insulator Components Parts

What are the main features of your Customized OEM Alumina Ceramic Insulators?

These insulators use Al2O3 (alumina) in 95%, 99%, or 99.5% purity grades. High alumina content ensures excellent electrical insulation, heat resistance, and mechanical strength. They handle extreme temperatures up to 1700°C. Custom shapes, sizes, and surface finishes are available to meet specific needs.

Where are these alumina ceramic parts commonly used?

They are used in industries requiring reliable insulation under harsh conditions. Examples include electronics, aerospace, automotive systems, and power generation equipment. Typical applications include insulating spark plugs, protecting sensors in high-temperature environments, and isolating components in circuit breakers.

How does higher alumina purity (99.5%) improve performance?

Higher alumina content increases density and durability. Parts made with 99.5% Al2O3 resist wear better. They handle higher voltages and temperatures compared to 95% or 99% grades. This makes them ideal for critical applications where failure risks must be minimized.

Can you produce insulators with complex shapes or tight tolerances?

Yes. Advanced molding, machining, and sintering techniques allow precise customization. Provide detailed drawings or samples. The manufacturing process ensures parts meet exact dimensions, even for intricate designs. Tolerances as tight as ±0.1mm are achievable.

What quality checks are performed on the finished products?

Every batch undergoes rigorous testing. X-ray fluorescence (XRF) confirms material purity. Dimensional inspections verify accuracy. Mechanical tests check hardness and strength. Electrical tests assess insulation performance. Certifications like ISO 9001 guarantee consistent quality. Defective units are rejected before delivery.

( Customized OEM 95% 99% 99.5% Al2O3 Alumina Ceramic Insulator Components Parts)

REQUEST A QUOTE

RELATED PRODUCTS

Wear-resistant Alumina Ceramic Sheets Industrial Wear-resistant Ceramics Alumina Ceramics

Al2O3 Ceramic Hot Selling Refractory Alumina Brick Kiln Rotary Kiln Building Making Clay Brick For Oven

Precision Ceramic Tubes High Temperature Resistant High Hardness 99% Alumina Ceramic Parts

High Temperature Alumina Ceramic And Temperature Resistant For Alumina Ceramic Tube

High Alumina Ceramic Heater Rod Porcelain Components 95