Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

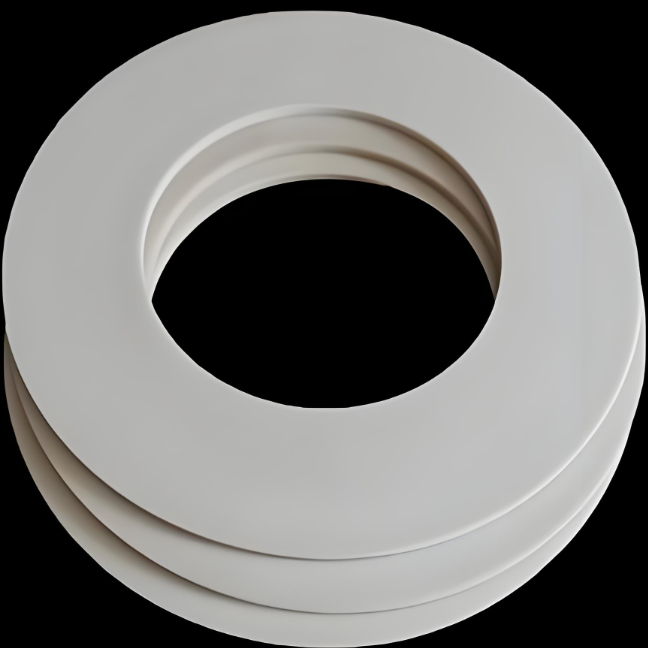

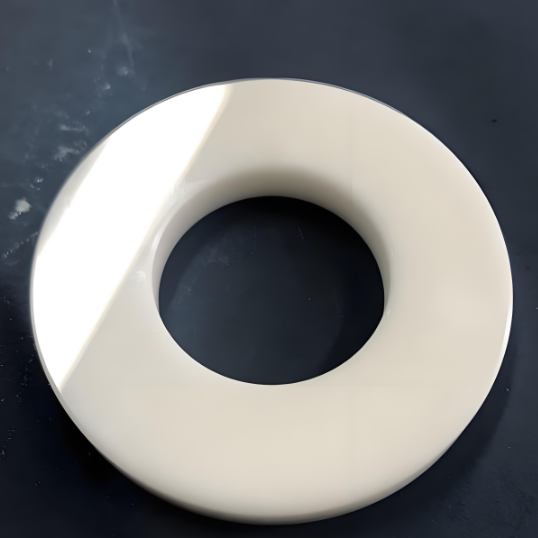

Overview of aluminium oxide round ceramic plates

Aluminium oxide ceramic plates, commonly known as alumina ceramic plates, are advanced ceramics made primarily from aluminium oxide (Al₂O₃). These materials exhibit a high degree of hardness, excellent wear resistance, and superior thermal stability. They are also electrically insulating while being thermally conductive to some extent, which makes them suitable for a wide range of applications in industries like electronics, machinery, and aerospace.

Features of Aluminium Oxide Ceramic Plates

- High Hardness and Strength: Alumina ceramics have a very high Vickers hardness value, making them resistant to scratching and deformation.

- Chemical Inertness: They show good resistance against chemical attack by acids and alkalis.

- Thermal Stability: These ceramics can withstand high temperatures without degrading or losing their properties.

- Electrical Insulation: High dielectric strength makes them ideal for electrical insulation.

- Low Thermal Expansion: They have a low coefficient of thermal expansion, reducing the risk of cracking under thermal stress.

- Biocompatibility: Suitable for medical applications due to non-toxicity and inertness.

Specifications of Aluminium Oxide Ceramic Plates

| Property | Symbol/Unit | Typical Value(s) |

|---|---|---|

| Chemical Composition | Al₂O₃ (%) | 90 – 99.9+ |

| Density | ρ (g/cm³) | 3.5 – 4.0 |

| Hardness (Vickers) | HV | 1200 – 2000 HV |

| Compressive Strength | σc (MPa) | 3000 – 4000 |

| Flexural Strength | σf (MPa) | 300 – 600 |

| Fracture Toughness | KIC (MPa·m^½) | 3 – 5 |

| Young’s Modulus | E (GPa) | 350 – 400 |

| Poisson’s Ratio | ν | 0.20 – 0.25 |

| Thermal Expansion Coefficient | α (×10⁻⁶/K) | 7 – 8.5 |

| Thermal Conductivity | λ (W/m·K) | 25 – 35 |

| Specific Heat Capacity | c (J/kg·K) | 750 – 900 |

| Electrical Resistivity | ρ (Ω·cm) | >10¹² |

| Dielectric Constant | εr (@1 MHz) | 9 – 10 |

| Loss Tangent | tan δ (@1 MHz) | <0.0001 |

| Operating Temperature | T (°C) | Up to 1700 |

Applications of Aluminium Oxide Ceramic Plates

- Electronics Industry: Used in substrates, insulators, and heat sinks.

- Mechanical Engineering: For bearings, seals, and cutting tools.

- Medical Devices: Artificial joints, dental implants, and surgical instruments.

- Automotive Industry: Spark plugs, sensors, and brake components.

- Chemical Industry: Corrosion-resistant linings and crucibles for chemical processing.

- Aerospace: Components that require high temperature and wear resistance.

Production Method of Aluminium Oxide Ceramic Plates

The production process typically involves:

Machining and Finishing: Post-sintering processes may include grinding, polishing, or adding coatings to achieve the final product specifications.

Powder Preparation: Starting with high-purity aluminium oxide powders.

Forming: Compacting the powder into the desired shape using methods such as dry pressing, isostatic pressing, or slip casting.

Sintering: Heating the formed part at high temperatures to fuse the particles together without melting them.

Company Profile

Advanced Ceramics founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2012, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Aluminum Nitride Ceramic Products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Aluminium Oxide Ceramic Plates

- What is the purity level of aluminium oxide used in these plates?

- The purity can vary but often ranges from 90% to 99.9%, depending on the application requirements.

- Can alumina ceramic plates be machined after sintering?

- Yes, they can be machined, but it requires specialized equipment due to their hardness.

- Are there any environmental concerns with disposing of alumina ceramics?

- Generally, there are no significant environmental hazards associated with alumina ceramics; however, proper disposal should always be considered.

- How does the cost of alumina ceramic plates compare to metal equivalents?

- Typically, alumina ceramics are more expensive upfront but offer long-term savings due to durability and reduced maintenance.

- Is it possible to bond alumina ceramic plates to metals?

- Yes, bonding is possible using specialized adhesives or through metallization and brazing techniques.

REQUEST A QUOTE

RELATED PRODUCTS

High Alumina Ceramic Heater Rod Porcelain Components 95

Customization 99% Alumina Ceramic Tube For Furnace Heater

Long Service Life Materials Made of Ceramics 95 99 Al2o3 Insulator Alumina Ceramic Ring

Al2O3 Ceramic mutiple size aluminium oxide ceramic tubes

95% 99% Ceramic Pipe High Purity Heat Resistance Alumina Ceramic Tube