Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

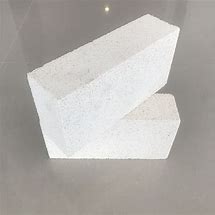

(Insulating Al2o3 Ceramic Thin Plate Alumina Ceramic Substrate 95)

Specifications of Insulating Al2o3 Ceramic Thin Plate Alumina Ceramic Substrate 95

The Insulating Al2O3 Ceramic Thin Plate Alumina Ceramic Substratum 95 is a high-performance material created for industrial and electronic applications. It is made from 95% aluminum oxide (Al2O3), ensuring outstanding electrical insulation and thermal security. The plate operates in temperature levels as much as 1600 ° C, making it ideal for high-heat environments. Its reduced thermal development coefficient lowers risk of splitting under quick temperature changes.

The substratum has a thickness of 3.6 g/cm FIVE, supplying strong mechanical longevity. It withstands wear, corrosion, and chemical erosion from acids or antacid. The surface area is smooth, with a roughness below Ra 0.4 µm, suitable for precision applications. Standard thickness ranges from 0.5 mm to 5 mm. Custom sizes are readily available, including common dimensions like 100×100 mm or 50×50 mm.

Electric insulation residential properties are essential. The dielectric stamina goes beyond 10 kV/mm, protecting against existing leak in high-voltage setups. The dielectric continuous remains secure in between 1 MHz and 10 GHz, making it reliable for RF and microwave circuits. Thermal conductivity is 24-28 W/m · K, permitting reliable warm dissipation in power electronics.

The material is compatible with thin-film and thick-film processes. It sustains display printing, metallization, and laser machining. This versatility allows usage in LED components, semiconductor packaging, and sensing unit components. Home plate is chemically inert, preventing responses with the majority of metals or gases during processing.

Product packaging guarantees safe shipment. Each plate is independently covered in anti-static foam or vacuum-sealed. Mass orders make use of enhanced boxes to avoid damage. Taking care of referrals consist of using gloves to stay clear of surface area contamination. Storage space problems require a dry atmosphere below 30 ° C to keep efficiency.

Applications extend electronic devices, aerospace, vehicle, and power sectors. Common usages include motherboard, heating elements, and insulating layers. The substratum’s combination of thermal monitoring, electrical resistance, and mechanical strength makes it a flexible remedy for innovative engineering requirements.

(Insulating Al2o3 Ceramic Thin Plate Alumina Ceramic Substrate 95)

Applications of Insulating Al2o3 Ceramic Thin Plate Alumina Ceramic Substrate 95

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Insulating Al2o3 Ceramic Thin Plate Alumina Ceramic Substrate 95

What is the Al2O3 ceramic thin plate made of? The plate uses alumina (Al2O3) as the main material. It contains 95% alumina. This makes it strong. It handles high heat well. It insulates electricity effectively. The material resists chemicals. It stays stable in tough conditions.

What are the key features of this ceramic plate? The plate works for high temperatures. It moves heat quickly. It blocks electricity completely. It resists acid and alkali damage. It lasts long under stress. The surface stays smooth. This helps in precise setups.

Where is the Al2O3 ceramic substrate commonly used? It fits electronics needing insulation. Examples include circuit boards. It works in heaters and sensors. Industrial machines use it. High-power devices need it. LED lights rely on it. Labs apply it for testing.

How much heat can the ceramic plate handle? It survives up to 1600°C. It keeps shape under extreme heat. No cracks form. Performance stays steady. It cools down fast. This prevents damage.

How is the ceramic plate installed? Use epoxy glue. Mechanical clamps also work. Clean the surface first. Remove dirt or oil. Check alignment before fixing. Avoid hard impacts. Follow safety steps.

(Insulating Al2o3 Ceramic Thin Plate Alumina Ceramic Substrate 95)

REQUEST A QUOTE

RELATED PRODUCTS

Alumina Ceramic Material and Industrial Ceramic Application Honeycomb Ceramic for RTO RCO

Al2O3 Ceramic Hot Selling Refractory Alumina Brick Kiln Rotary Kiln Building Making Clay Brick For Oven

Customizable Alumina 99 Porcelain Ceramic Tube Insulated Al2O3 Ceramic Tubes Moulded Ceramic Plates

Factory Direct Alumina Ceramic – Wear-resistant and High-temperature Resistant Ceramic for Customized Processing

Custom Corundum Wear-resistant Alumina Ceramic Piece Al2O3 Ceramic Sheets